A light decolorization device for producing white pepper

A white pepper and decolorization technology, applied in the directions of packaging, application, transportation and packaging, can solve the problems of production site restrictions and weather effects, susceptibility to environmental pollution, extensive production processes, etc. Low, high luminous efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

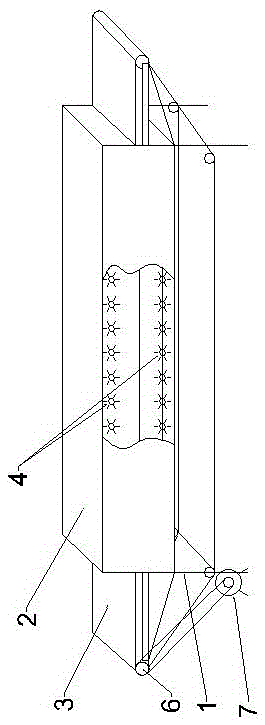

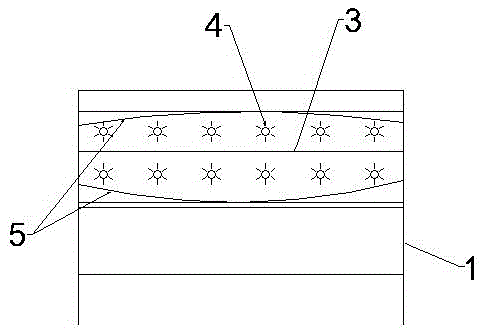

[0014] Below in conjunction with all accompanying drawings the present invention will be further described, and preferred embodiment of the present invention is: see appended figure 1 And attached figure 2 , the light decolorization device that the production white pepper described in the present embodiment is used comprises frame 1, decolorization tunnel 2, conveyer belt 3, light source 4, sprocket wheel 6, variable frequency motor 7, wherein, conveyer belt 3 is installed on frame 1 Above, its two ends protrude from the frame 1 to form an input end and an output end, and the conveyor belt 3 at one end is connected to the frequency conversion motor 7 at the bottom of the frame 1 through a sprocket 6 and a chain belt. The conveyor belt 3 adopts The stainless steel wire is woven into a mesh shape, the diameter of the stainless steel wire used is 1.4mm, and the mesh after weaving is 12×25mm; the upper part of the frame 1 is provided with a decolorization tunnel 2, and the decolo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com