Screw taking structure

A screw and pick-up claw technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of slow manual operation and inconsistent quality control, and achieve the effect of process control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

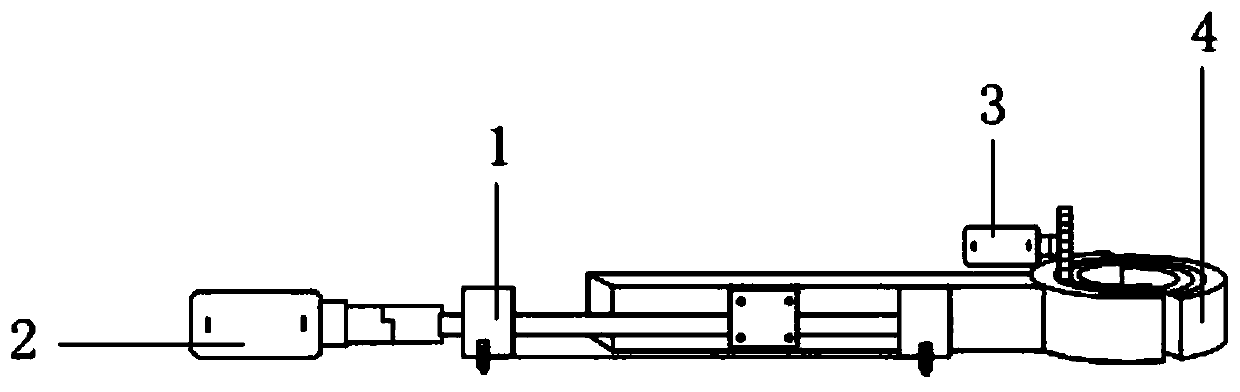

[0015] The screw reclaiming structure is characterized in that it includes a screw mechanism 1, a screw motor 2, a reclaiming motor 3, and a reclaiming claw head 4; the screw motor 3 is connected to the screw mechanism 1 through a coupling to drive the screw Rotation, the screw rod mechanism 1 has threads on the screw rod, which drives the slider to move left and right through the rotation of the screw rod. 4. A complete circle is formed by two fixed and rotating arcs. There is a toothed belt on the rotating arc. The reclaiming motor 3 and the motor shaft are installed with gears through structural parts, which are connected with the teeth on the reclaiming claw head 4. The belt is engaged to drive the reclaiming claw head 4 to close or open. The reclaiming motor 3 is installed on the reclaiming rod of the reclaiming mechanism through screws. The reclaiming claw head 4 has a chute structure on the reclaiming rod. After the reclaiming claw head 4 is closed, the diameter is sm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com