Water-based composite slurry and preparation method thereof

A composite slurry, water-based technology, applied in pigment slurry, anti-fouling/underwater coating, climate sustainability, etc., can solve problems such as excess, poor wettability, and failure to flow normally

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0063] The present invention also provides a method for preparing the water-based composite slurry described in the above-mentioned technical solution, comprising the following steps:

[0064] a) mixing water, wetting agent, pH regulator, defoamer, dispersant and thickener to obtain a mixed dispersant;

[0065] b) mixing and dispersing the mixed dispersant with diatomaceous earth and pigments and fillers to obtain a prefabricated mixed slurry;

[0066] c) mixing and dispersing the prefabricated mixed slurry and the anti-mildew bactericide to obtain an aqueous composite slurry.

[0067] Among them, the types, dosages and sources of water, wetting agents, pH regulators, defoamers, dispersants, thickeners, diatomaceous earth, pigments and fillers, and anti-mold and fungicides are all consistent with those described in the above technical solutions , which will not be repeated here.

[0068] Regarding step a): the mixing method is not particularly limited, and it is sufficient t...

Embodiment 1

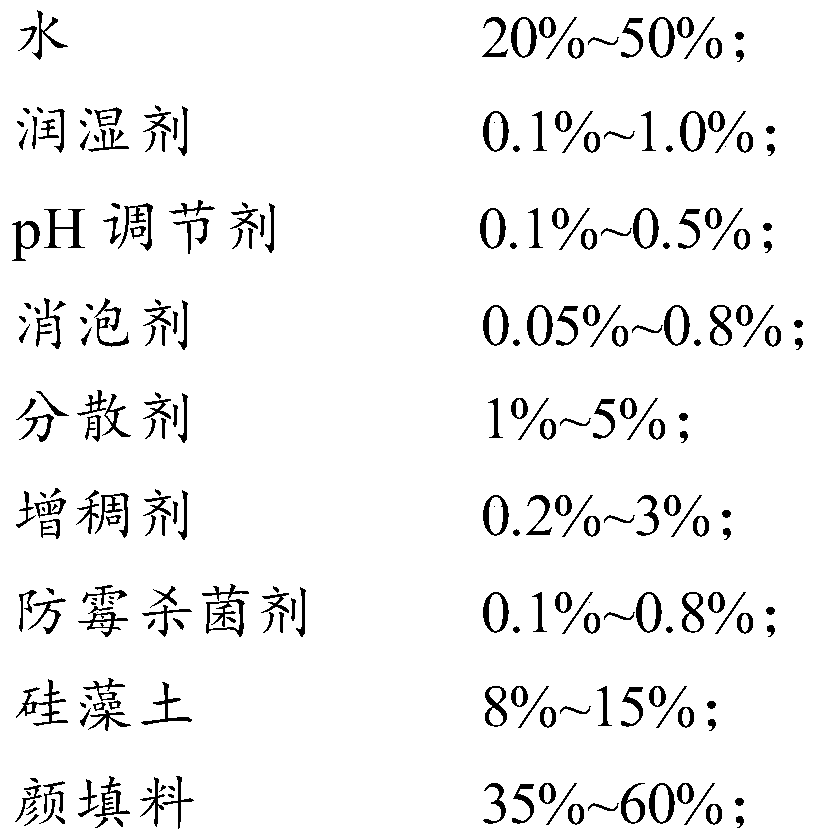

[0075] 1.1 Formula:

[0076]

[0077] Among them, the diatomite is calcined diatomite CELITE 490 with a particle size of 20-40 μm; the particle size of the pigment and filler is 200-400 nm; the pH of the slurry system is above 8.

[0078] 1.2 Preparation

[0079] S1. Add water, wetting agent, pH regulator, defoamer, dispersant and thickener into a stainless steel container and mix to obtain a mixed dispersant.

[0080] S2. Turn on the disperser, adjust the initial speed to 500r / min, slowly add diatomaceous earth and pigments and fillers to the mixed dispersant in turn, after the addition, adjust the speed of the dispersant to 1200r / min, disperse at high speed for 20min, until the slurry is evenly mixed . Use the scraper fineness meter to test the fineness of the slurry, if it reaches ≤40μm, the test is qualified.

[0081] S3. Add anti-mold and fungicide to the slurry, adjust the speed of the disperser to 1000r / min, disperse for 10min until the slurry is evenly mixed, and...

Embodiment 2

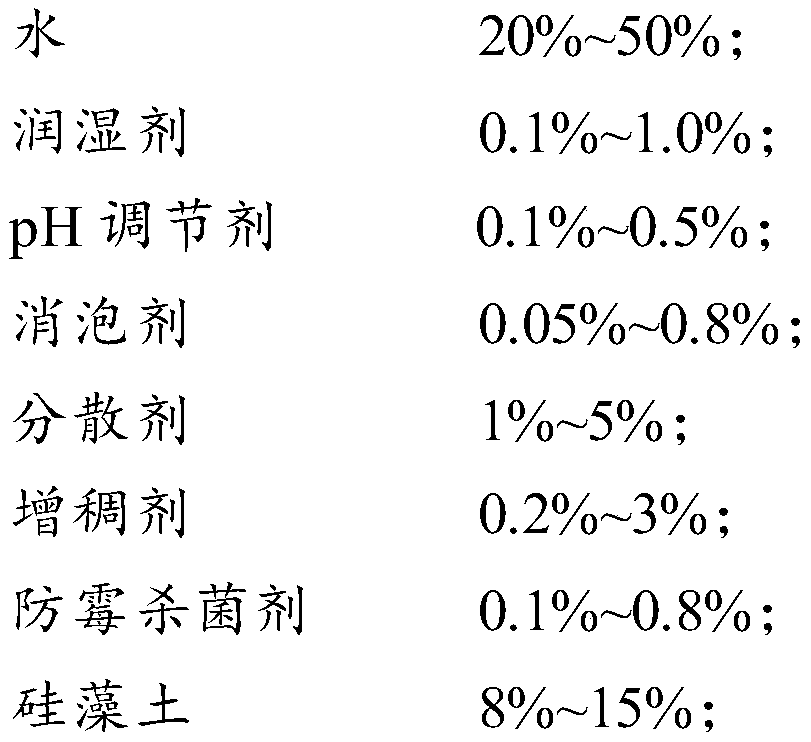

[0083] 1.1 Formula:

[0084]

[0085] Among them, the diatomite is calcined diatomite MGZ-600 with a particle size of 20-40 μm; the particle size of the pigment and filler is 700 mesh; the pH of the slurry system is above 8.

[0086] 1.2 Preparation: Same as Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com