Integrated wire-wound DC tuning fork, plug and method for manufacturing the same

An integrated, wire-based technology, applied in the manufacture of contacts, assembly/disassembly of contacts, contact parts, etc., can solve problems such as instantaneous circuit breaks, easy tin drop, poor contact, etc., to achieve improved structure, cost savings, and enhanced reliability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

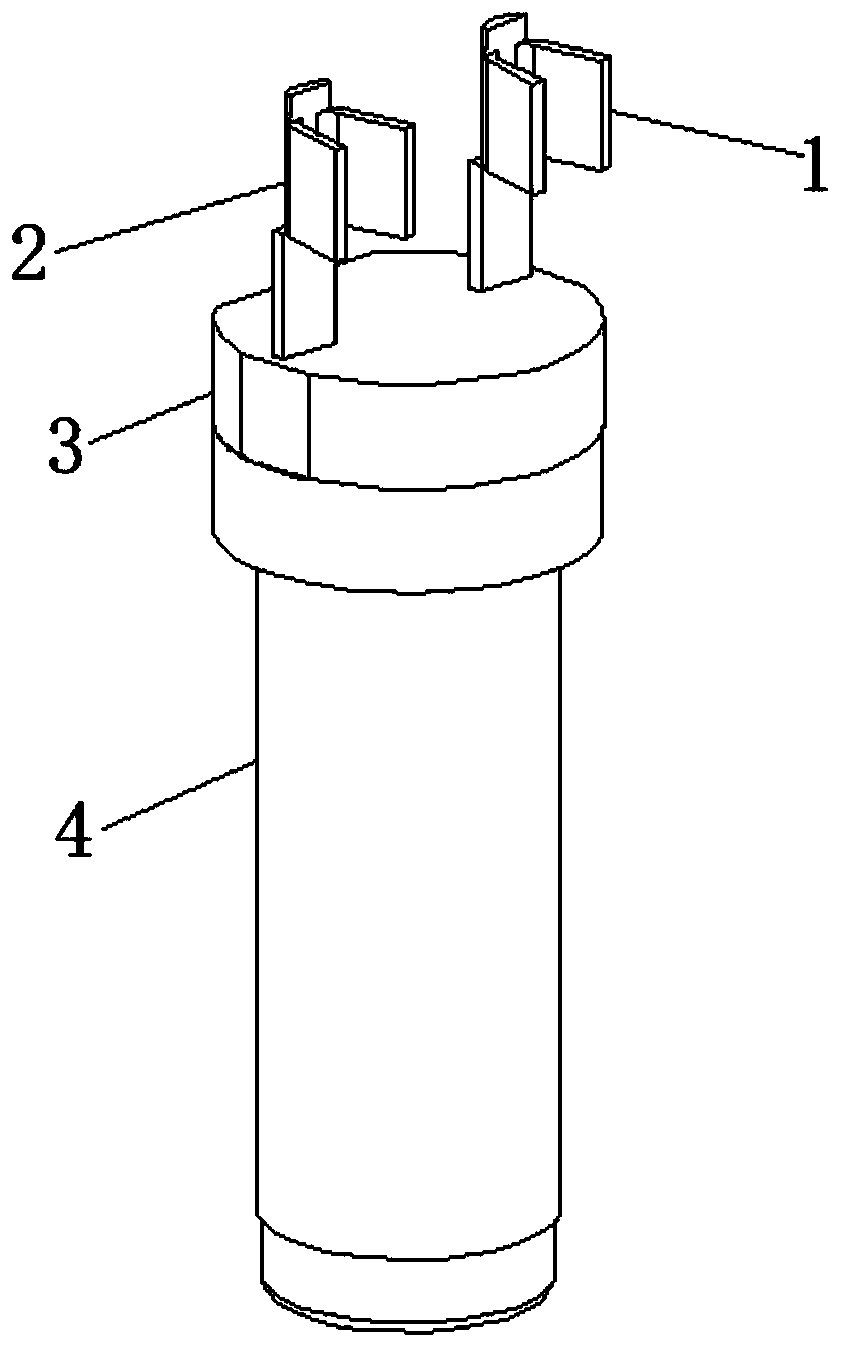

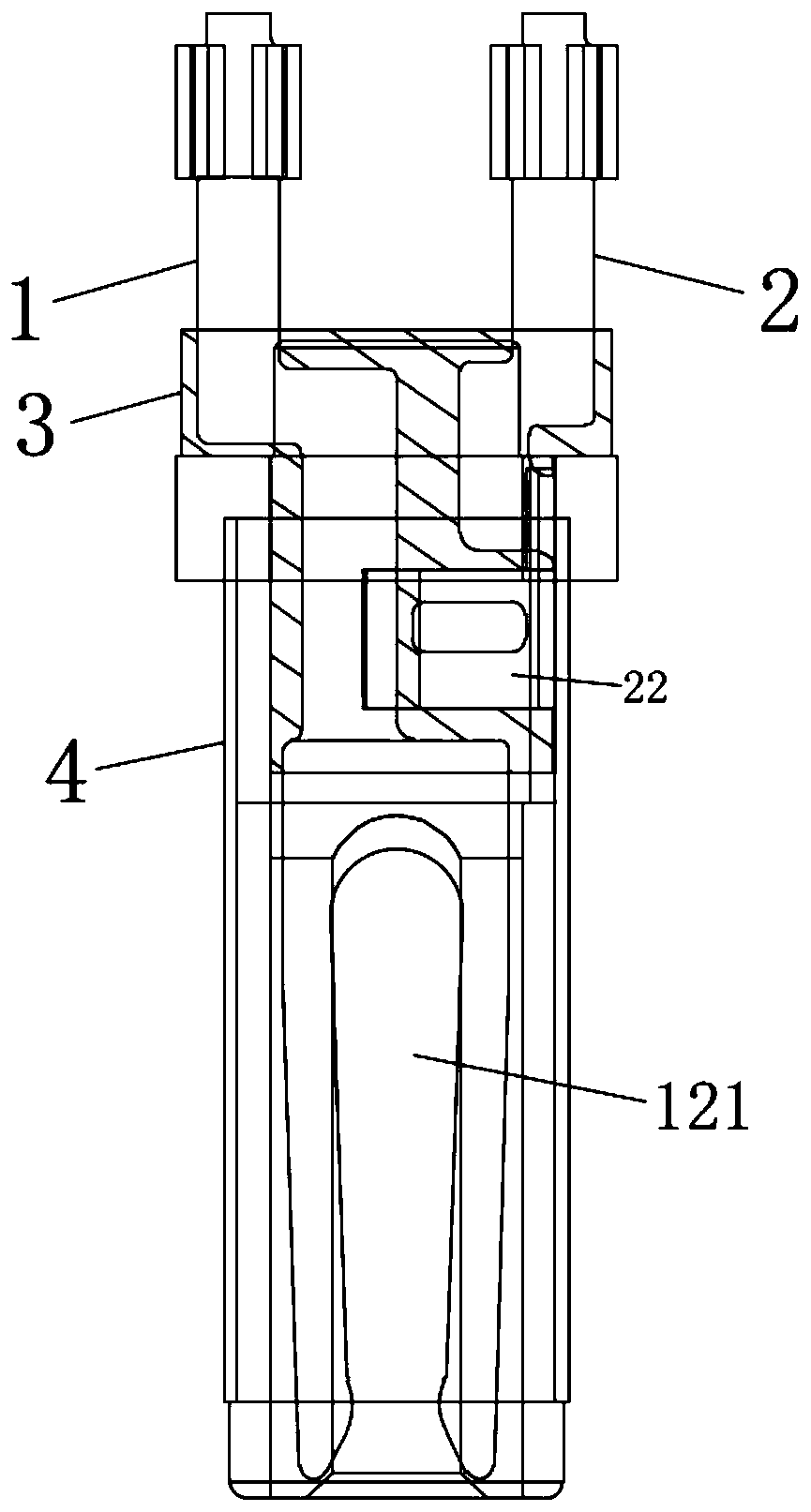

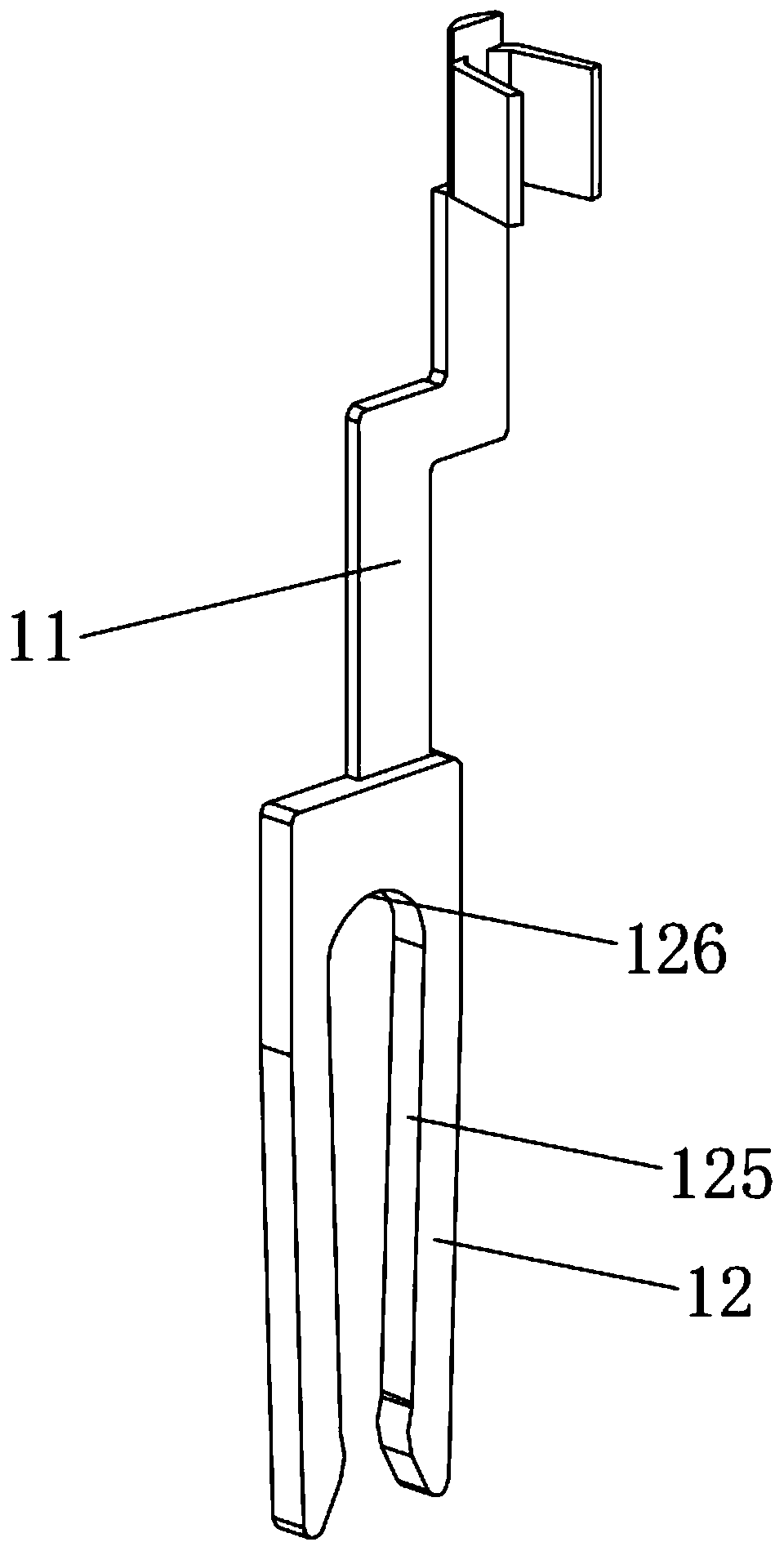

[0028] see Figure 1-9 As shown, the present invention relates to an integrated wire-bonding type DC tuning fork, which includes a lead terminal and a tube body 4, the lead terminal is sleeved in the tube body 4, and the lead terminal includes a first electrode 1, a second electrode The second electrode 2 and the inner mold 3, the first electrode 1 includes a conductive connecting piece 11 and a contact elastic piece 12, the thickness of the conductive connecting piece 11 is smaller than that of the contact elastic piece 12, and the conductive connecting piece 11 and the contact elastic piece 12 are integrally formed , The traditional conductive connection piece and the contact spring piece are manufactured by different equipment, and then welded together by soldering. The traditional method is how to change the connection structure of the two to avoid quality problems caused by welding. No one skilled in the art has thought of using different thicknesses of conductive connecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com