Multicomponent polymer for rigid polyvinyl chloride and preparation method of multicomponent polymer

A rigid polyvinyl chloride, multi-component technology, applied in the field of new processing modifiers for rigid polyvinyl chloride (hereinafter referred to as PVC) and its preparation, can solve the problem of deviation from the overall plan, narrow processing range, rigid PVC Improve the melt strength and balance torque, improve the surface finish, and excellent self-lubricating performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

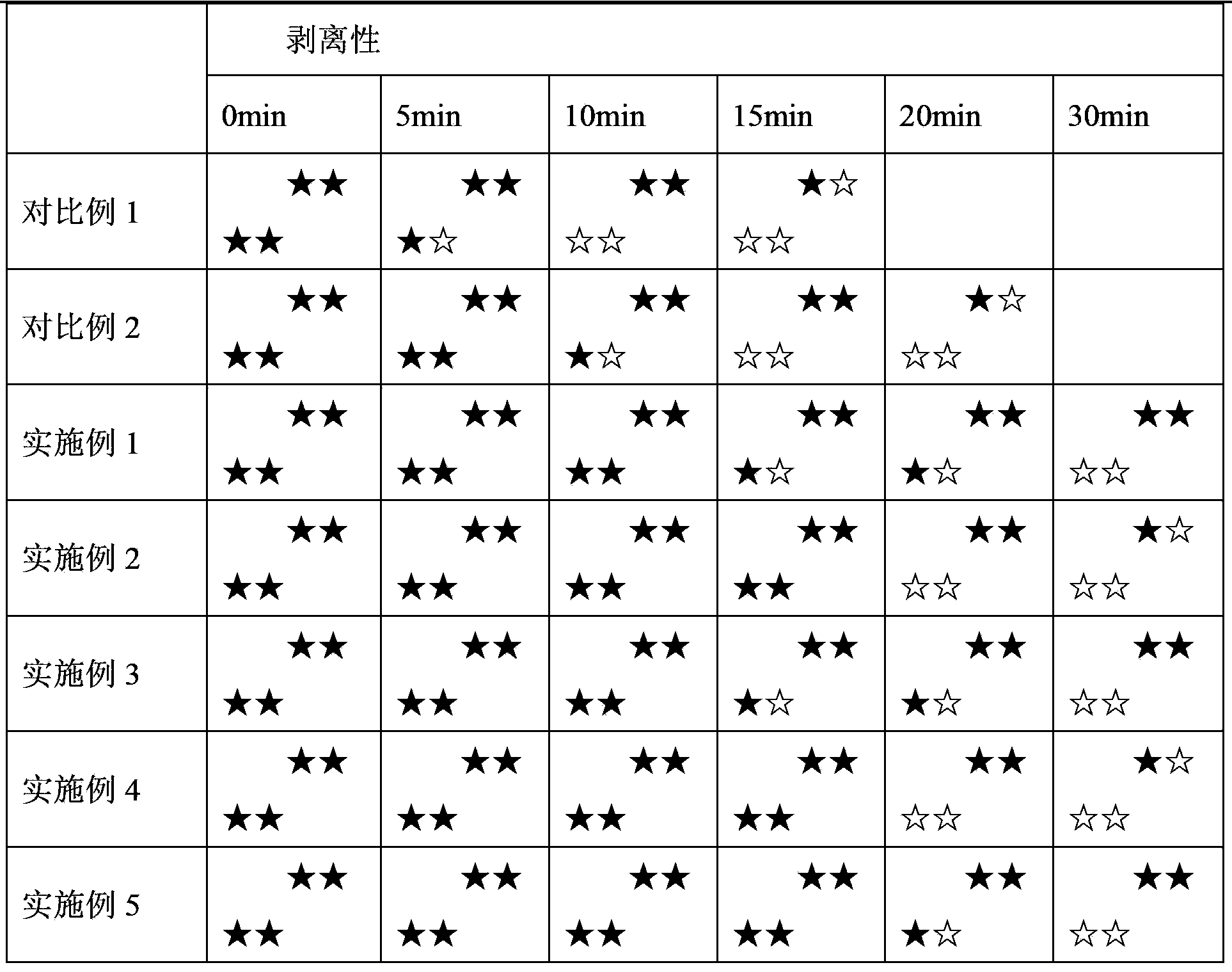

Examples

Embodiment 1

[0035] (1) Preparation of polymer emulsion intermediate A:

[0036] First, 100 parts by weight of monomers (1 part by weight of methacrylic acid, 99 parts by weight of vinyl acetate), 250 parts by weight of water, 1.0 parts by weight of polyvinyl alcohol, and 0.5 parts by weight of sodium lauryl sulfate are added to the reaction device; Raise the temperature to 60°C at a stirring speed of 300 rpm, add 0.01 parts by weight of potassium persulfate, control the reaction temperature below 80°C, react for 8 hours, add 5 parts by weight of sodium lauryl sulfate, cool down and discharge, and obtain a polymer Product emulsion intermediate A;

[0037] (2) Preparation of polymer emulsion intermediate B:

[0038] 100 parts by weight of monomers (1 part by weight of isooctyl acrylate, 99 parts by weight of methyl methacrylate), 300 parts by weight of water, and 0.5 parts by weight of sodium lauryl sulfate are added to the reaction device; at 300 rpm Raise the temperature to 80°C under s...

Embodiment 2

[0042] (1) Preparation of polymer emulsion intermediate A:

[0043] First, 100 parts by weight of monomers (5 parts by weight of methacrylic acid, 95 parts by weight of vinyl acetate), 250 parts by weight of water, 5.0 parts by weight of polyvinyl alcohol, and 3.0 parts by weight of sodium dodecylbenzenesulfonate are added to the reaction device ; heat up to 55°C at a stirring speed of 300 rpm, add 0.05 parts by weight of potassium persulfate, control the reaction temperature below 80°C, react for 5 hours, add 10 parts by weight of sodium lauryl sulfate, cool down and discharge, Obtain polymer emulsion intermediate A;

[0044] (2) Preparation of polymer emulsion intermediate B:

[0045]Add 100 parts by weight of monomers (10 parts by weight of ethyl acrylate, 90 parts by weight of methyl methacrylate), 300 parts by weight of water, and 3.0 parts by weight of sodium lauryl sulfate into the reaction device; stirring at 250 rpm Raise the temperature to 80°C at a high speed, add...

Embodiment 3

[0049] (1) Preparation of polymer emulsion intermediate A:

[0050] First, 100 parts by weight of monomers (5 parts by weight of methacrylic acid, 95 parts by weight of vinyl acetate), 300 parts by weight of water, 4.0 parts by weight of polyvinyl alcohol, and 2.0 parts by weight of sodium dodecylbenzenesulfonate are added to the reaction device ;Heat up to 50°C at a stirring speed of 50 rpm, add 0.05 parts by weight of potassium persulfate, control the reaction temperature below 80°C, react for 5 hours, add 5 parts by weight of aqueous silica, cool down and discharge, and obtain polymerization Product emulsion intermediate A;

[0051] (2) Preparation of polymer emulsion intermediate B:

[0052] Add 100 parts by weight of monomers (5 parts by weight of butyl acrylate, 95 parts by weight of methyl methacrylate), 300 parts by weight of water, and 3.0 parts by weight of sodium lauryl sulfate into the reaction device; stirring at 250 rpm Raise the temperature to 80°C at a high s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com