Leather scrap modified rubber outsole and preparation method thereof

A technology for modifying rubber and leather, applied in shoe soles, applications, clothing, etc., can solve the problem that composite materials cannot be applied to outsole, and achieve high-value utilization, reduce production costs, and realize the effect of resource recycling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] A preparation method for leather crumb modified rubber outsole, comprising the steps of:

[0040] Step (1): Preparation of leather shavings grafted polybutadiene

[0041] a) Put the tanned leather scraps and recycled waste leather products into a vacuum drying oven, and dry them in a vacuum at a drying temperature not higher than 90°C to obtain dried leather waste;

[0042] b) crushing and grinding the dried leather waste to obtain leather shavings of 50-600 mesh;

[0043] c) Take maleic anhydride grafted polybutadiene with a grafting rate of not less than 15%, put the maleic anhydride grafted polybutadiene into a torque rheometer, and after it melts, add leather scraps, melt and graft branches, that is, leather shavings grafted polybutadiene.

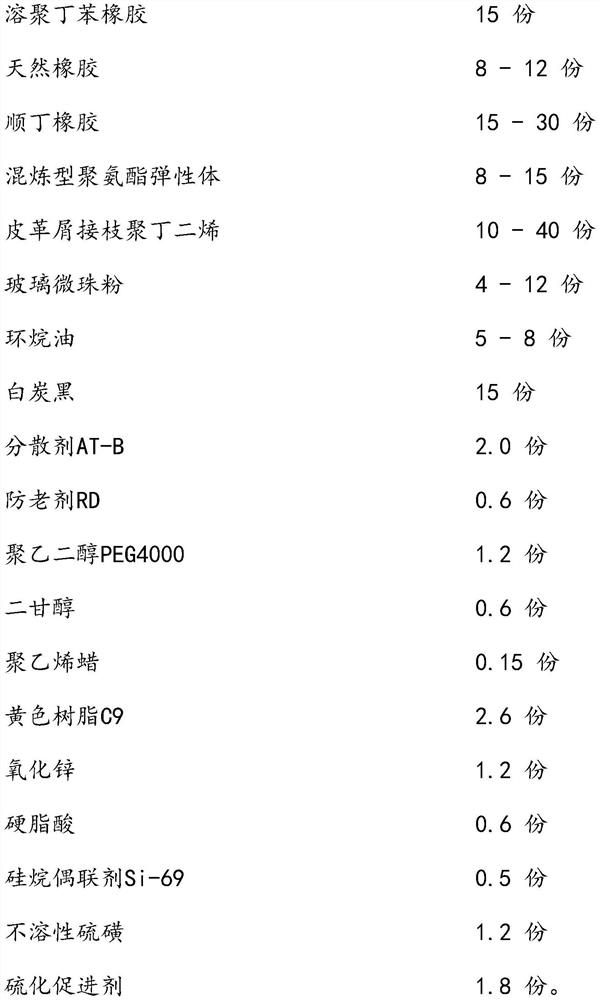

[0044] Step (2): Weigh 10 parts of natural rubber, 12 parts of mixing polyurethane elastomer (polymerized from polyether polyol, isocyanate and allyl ether), 25 parts of leather shavings grafted polybutadiene according to the ...

Embodiment 2

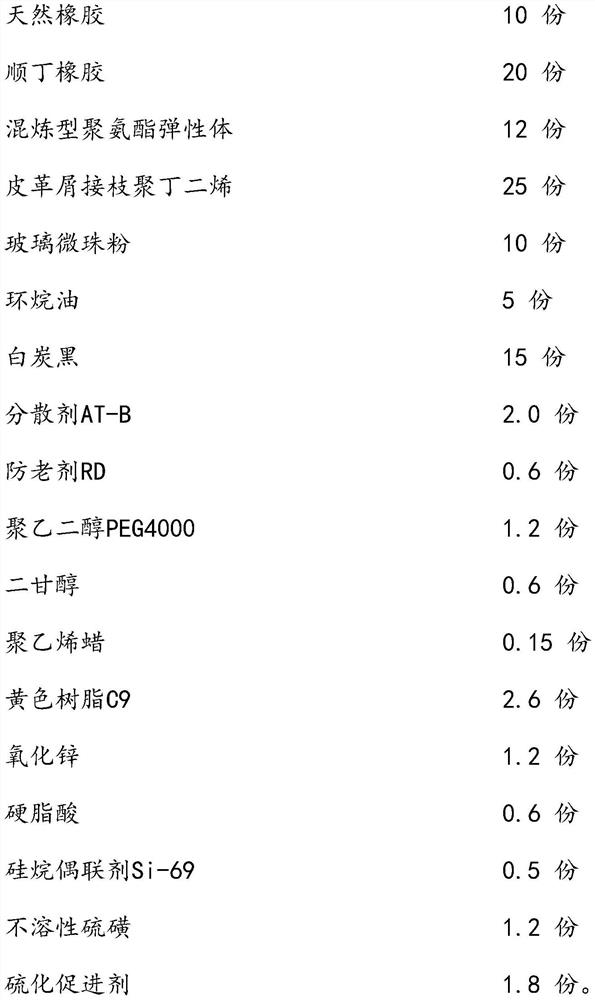

[0049] A kind of preparation method of leather crumb modified rubber outsole is basically the same as the preparation method in Example 1, the difference is:

[0050]

[0051]

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of grafting | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com