Brushless permanent magnet direct current motor for automobile

A permanent magnet DC, automotive technology, applied in electrical components, electromechanical devices, magnetic circuit static parts, etc., can solve the problems affecting the reliability and life of the motor, many contacts, and large installation space, to ensure electrical safety performance. and the effect of product quality requirements, simplified controllers, and improved reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

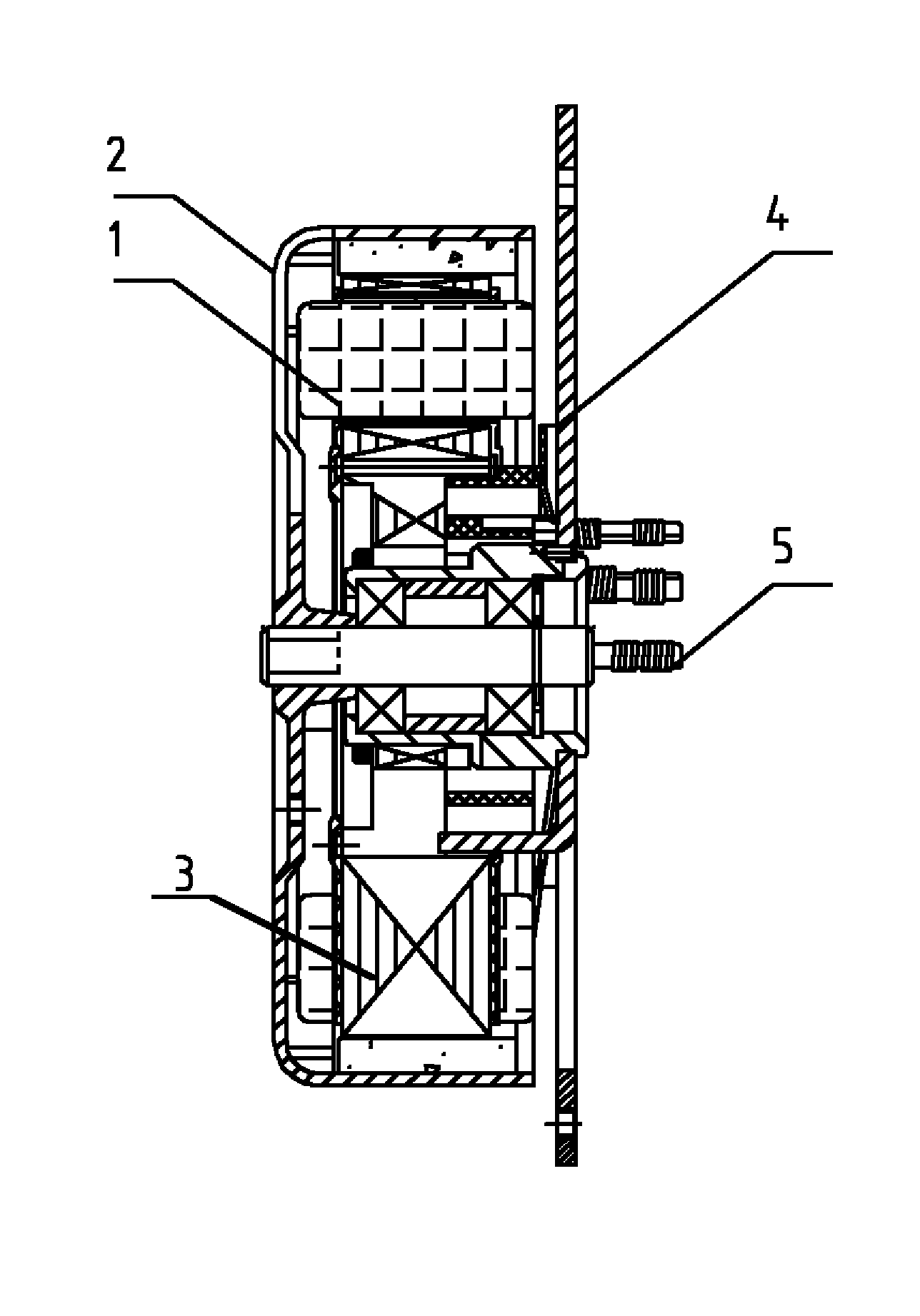

[0017] See figure 1 , Figure 5 As shown, the present invention includes a stator 1, an outer rotor 2, and an insulation system 3. The insulation system 3 includes a stator core 12, an insulation board, and an outlet socket 9. An insulation plug is placed between the stator core 12 and the polyester enameled round copper wire. plate, and 4 is the fixed plate.

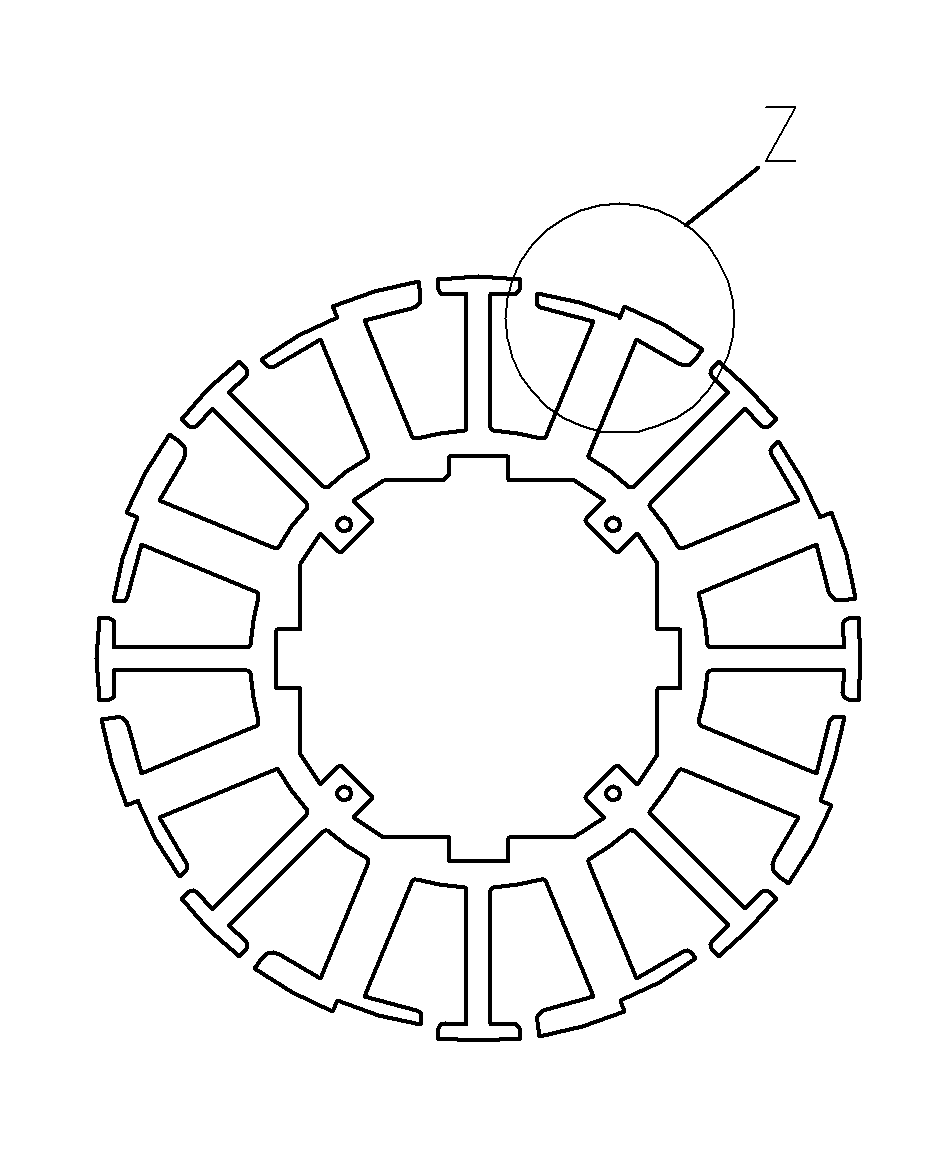

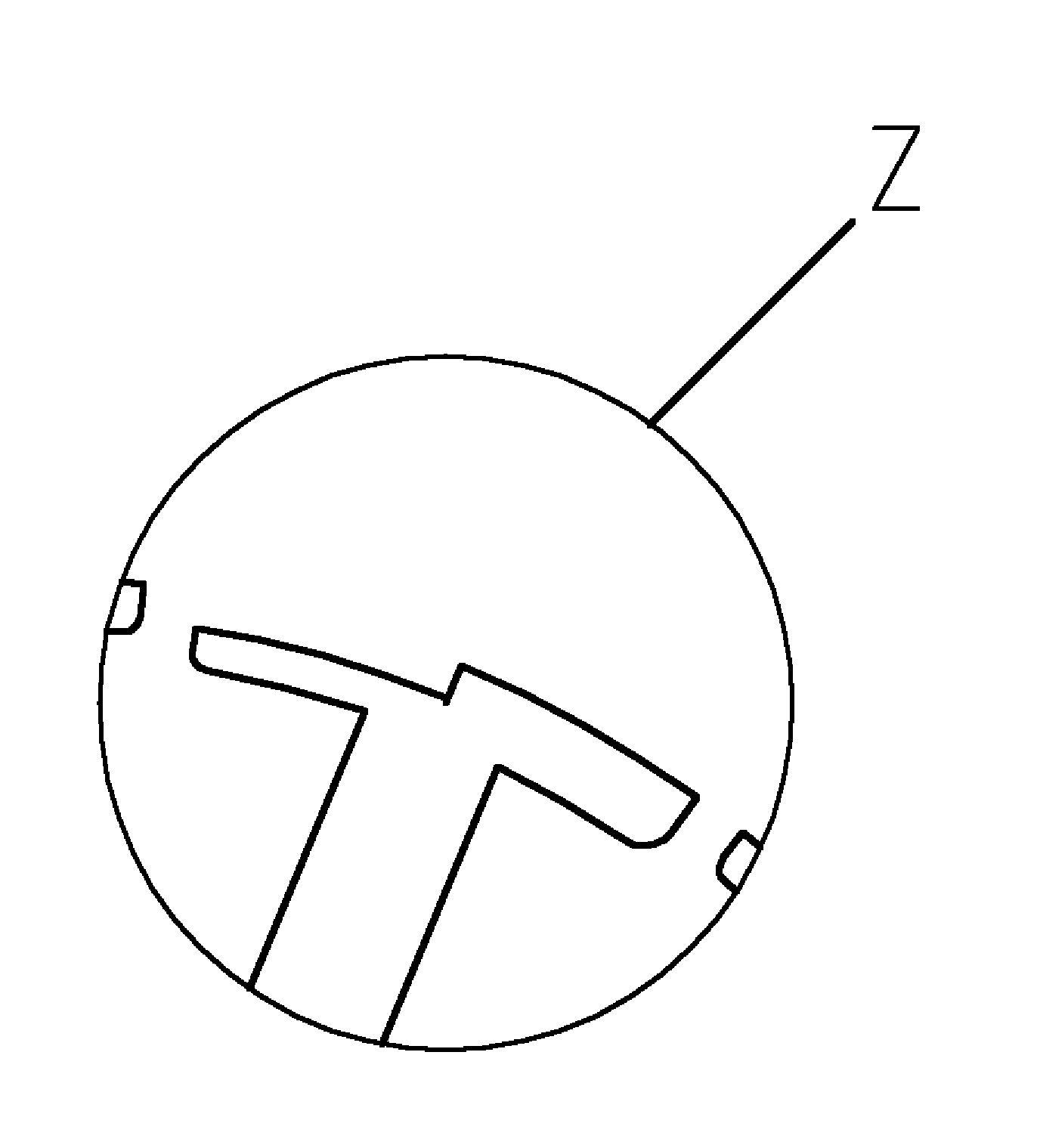

[0018] See figure 2 , image 3 and Figure 5 As shown, a magnetic field equivalent to a rotating magnetic field is designed to be established in the magnetic field, and a gap is designed in the T-shaped tooth portion of the stator 1 according to the magnetic circuit, so that the distribution of the air gap between the stator 1 and the outer rotor 2 is not uniform, and the magnetic field strength and torque are generated. Therefore, a rotating magnetic field is generated, and the outer rotor 2 is fixed to rotate in the direction of the gap, which improves the reliability of the brushless permanent magnet DC motor an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com