Pneumatic ram fully sealed feeding and discharging port of plastic powder mixing drum

A technology of pneumatic ram and discharge port, which is applied in the field of fully sealed feeding of the discharge port and the pneumatic ram of the mixing drum, which can solve the problems that automatic production cannot be achieved, automatic opening and closing cannot be realized, and plastic powder is easy to fall out of the cylinder, etc. problems, to achieve good sealing, fast opening and closing speed, and good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

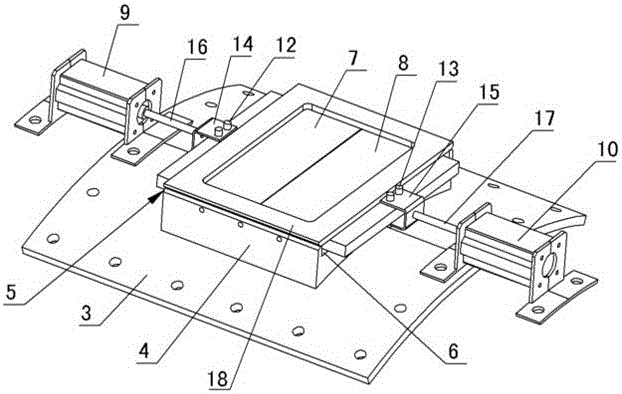

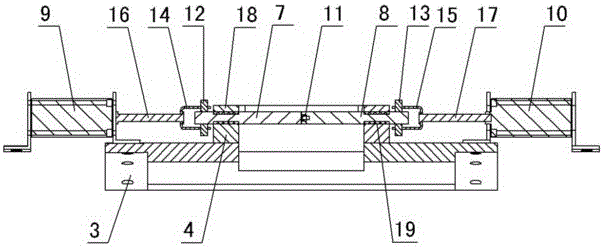

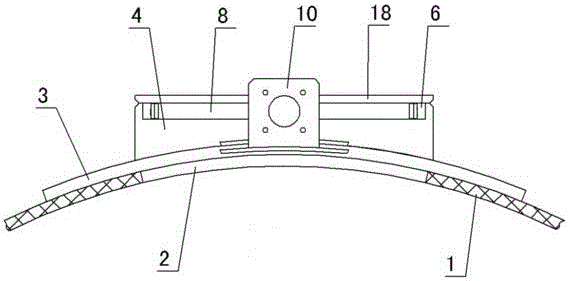

[0010] The invention relates to a fully sealed feeding and discharging port of a plastic powder mixing drum with a pneumatic gate, such as figure 1 — image 3 As shown, the cylinder body 1 including the mixing drum is provided with a feed and discharge port 2 on the cylinder body 1. It is characterized in that a cover plate 3 is installed around the feed and discharge port 2, and a gate seat is installed on the cover plate 3. 4. The left and right sides of the gate seat 4 are respectively made with a left gate groove 5 and a right gate groove 6, and a pressure plate 18 is installed on the left gate groove 5 and the right gate groove 6, and the left and right gate grooves 5 and 6 are connected with the pressure plate 18 are respectively provided with a left gate 7 and a right gate 8, the inner end faces of the left gate 7 and the right gate 8 are in contact, and there is a sealing device, the outer end of the left gate 7 is connected to the left cylinder 9, and the right gate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com