Multifunctional bundler

A strapping machine and multi-functional technology, which is applied to the parts of strapping machinery, strapping materials, packaging, etc., can solve the problems of bundling objects that cannot be small and irregular in appearance, reduce labor intensity, improve work efficiency, and fill technology lack of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

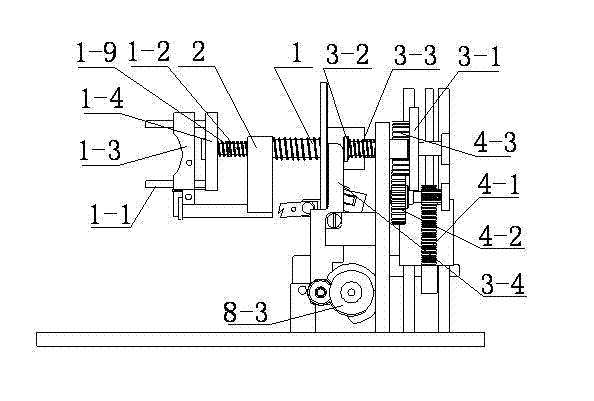

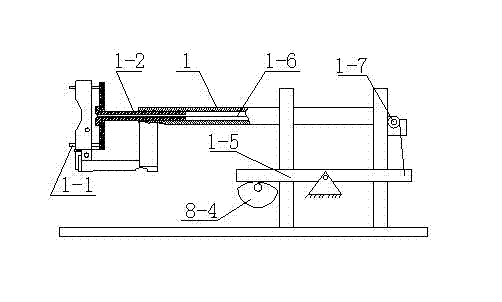

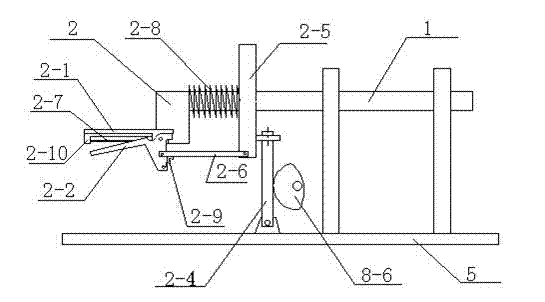

[0017] The structure of the multifunctional binding machine includes a combined cam driving mechanism assembly arranged on the frame, a pumping belt mechanism assembly, a belt winding mechanism assembly, and a cutting and bonding mechanism assembly. The important thing is: the winding The structure of the belt mechanism assembly includes: an intermediate transmission mechanism composed of a rack and pinion pair, a hollow shaft 1 connected to the gear 4-3, a solid shaft 1-2 with axial freedom with the hollow shaft 1, and a hollow shaft 1 The belt engaging mechanism positioned in the form of sliding fit, the hollow rotating shaft 1 brake locking mechanism, the belt winding positioning block 2 positioned at the end of the hollow rotating shaft 1, and the driving sliders 4-6 of the rack and pinion pairs rely on the intermediate connecting rod The driving mechanism and the pulleys positioned at both ends of the intermediate connecting rod and the hollow rotating shaft drive cam 8-1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com