Pure-cotton trademark tape and manufacturing method thereof

A production method and technology of trademark tape, applied in the direction of textile, fabric, fiber type, etc., can solve the problems of improving the process of trademark tape, and achieve the effect of strong adhesion, improved effect, and not easy to fall off.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0057] Embodiment one

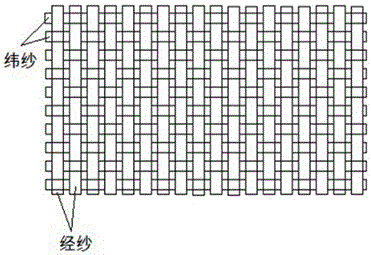

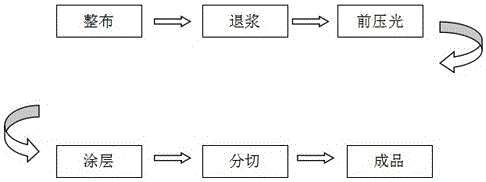

[0058] like figure 1 and figure 2 Shown, a kind of manufacture method of pure cotton trademark band, comprises the following steps successively:

[0059] (1) Base fabric pre-treatment: The base fabric layer is made of polyester warp and weft yarns, with a warp density of 20 threads / cm and a weft density of 20 threads / cm. Pass the base fabric layer through the cold pad-batch working fluid at 45m / min at 25°C to make the excess rate 100%-120%. The composition of cold pad batch working fluid is: NaOH40g / L, H 2 o 2 10g / L, water glass 10g / L, refining agent 20g / L, penetrant 5g / L. After the base cloth is cold-rolled, at 60°C, the composition is: NaOH30g / L, refining agent 5g / L, NaOH2 SO 3 1g / L deboiled one-bath working solution. After the first two steps are completed, the base cloth is washed in a water tank at 98°C until the pH is neutral, and the pretreatment is completed.

[0060] (2) Pre-calendering treatment: In order to better complete the coatin...

Example Embodiment

[0068] Embodiment two

[0069] like figure 1 and figure 2 Shown, a kind of manufacture method of pure cotton trademark band, comprises the following steps successively:

[0070] (1) Base fabric pre-treatment: The base fabric layer is made of polyester warp and weft yarns, the warp and weft counts are 32 yarns, the warp yarn density is 25 yarns / cm, and the weft yarn density is 25 yarns / cm . Pass the base fabric layer through the cold pad-batch working fluid at 45m / min at 25°C to make the excess rate 100%-120%. The composition of cold pad batch working fluid is: NaOH45g / L, H 2 o 2 11g / L, water glass 10g / L, refining agent 25g / L, penetrant 7g / L. After the base cloth is cold-rolled, at 60°C, the composition is: NaOH35g / L, refining agent 7g / L, NaOH 2 SO 3 3g / L deboiled one-bath working solution. After the first two steps are completed, the base cloth is washed in a water tank at 98°C until the pH is neutral, and the pretreatment is completed.

[0071] (2) Pre-calendering ...

Example Embodiment

[0079] Embodiment three

[0080] like figure 1 and figure 2 Shown, a kind of manufacture method of pure cotton trademark band, comprises the following steps successively:

[0081] (1) Base fabric pretreatment: The base fabric layer is made of polyester warp and weft yarns, the warp and weft counts are 32 yarns, the warp yarn density is 25 yarns / cm, and the weft yarn density is 30 yarns / cm . Pass the base fabric layer through the cold pad-batch working fluid at 45m / min at 25°C to make the excess rate 100%-120%. The composition of cold pad batch working fluid is: NaOH50g / L, H 2 o 2 12g / L, water glass 12g / L, refining agent 30g / L, penetrant 10g / L. After the base cloth is cold-rolled, at 60°C, the composition is: NaOH40g / L, refining agent 10g / L, NaOH 2 SO 3 5g / L deboiled one-bath working solution. After the first two steps are completed, the base cloth is washed in a water tank at 98°C until the pH is neutral, and the pretreatment is completed.

[0082] (2) Pre-calenderi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com