Manufacturing process of motor stator core

A manufacturing process and stator core technology, which is applied in the field of manufacturing process of motor stator core, can solve the problems of difficult to control thickness difference, non-uniform thickness, and uneven thickness of stator core, so as to eliminate uneven thickness and uniform thickness. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Embodiment 1: A manufacturing process of a motor stator core, comprising the following process steps:

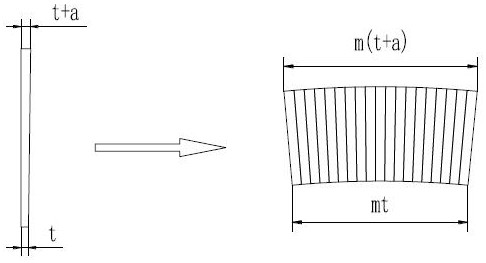

[0037] Pre-step: Detect the average thickness of the strip 1, and obtain the multiple relationship between the average thickness of the strip 1 and the thickness setting value of the stator core single block, so as to determine the stamping required to form a stator core single block The number of single stator core pieces;

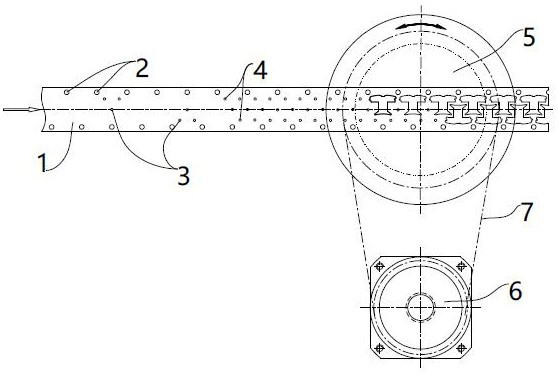

[0038] Step A, feeding: Take the strip material 1 and send it to the punching machine, so that the strip material 1 can continuously step forward and feed the material on the punching machine; There are 3 stations at the metering point, 4 stations at the punching point and blanking station. The schematic diagram of the stamping process line is as follows figure 1 shown;

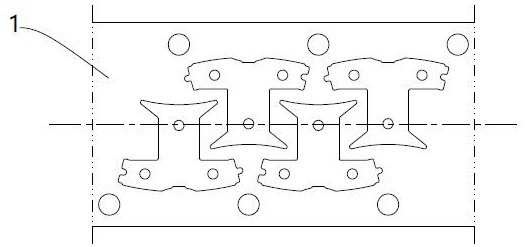

[0039] Step B, Punching the guiding hole 2: During the step forward feeding process of the strip 1, after each step, implement a punching of the guiding hole 2 on both sides o...

Embodiment 2

[0057] Embodiment 2: A manufacturing process of a motor stator core, comprising the following process steps:

[0058] Pre-step: Detect the average thickness of the strip 1, and obtain the multiple relationship between the average thickness of the strip 1 and the thickness setting value of the stator core single block, so as to determine the stamping required to form a stator core single block The number of single pieces of the stator core;

[0059] Step A, feeding: Take the strip material 1 and send it to the punching machine, so that the strip material 1 can continuously step forward and feed the material on the punching machine; There are 3 stations at the metering point, 4 stations at the punching point and blanking station. The schematic diagram of the stamping process line is as follows figure 1 shown;

[0060] Step B, Punching the guiding hole 2: During the step forward feeding process of the strip 1, after each step, implement a punching of the guiding hole 2 on both ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com