PI substrate, manufacturing method thereof and display device

A technology for display devices and substrates, applied in identification devices, semiconductor/solid-state device manufacturing, photovoltaic power generation, etc., can solve problems such as uneven edge thickness of PI films, achieve the effect of eliminating uneven edge thickness and improving yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

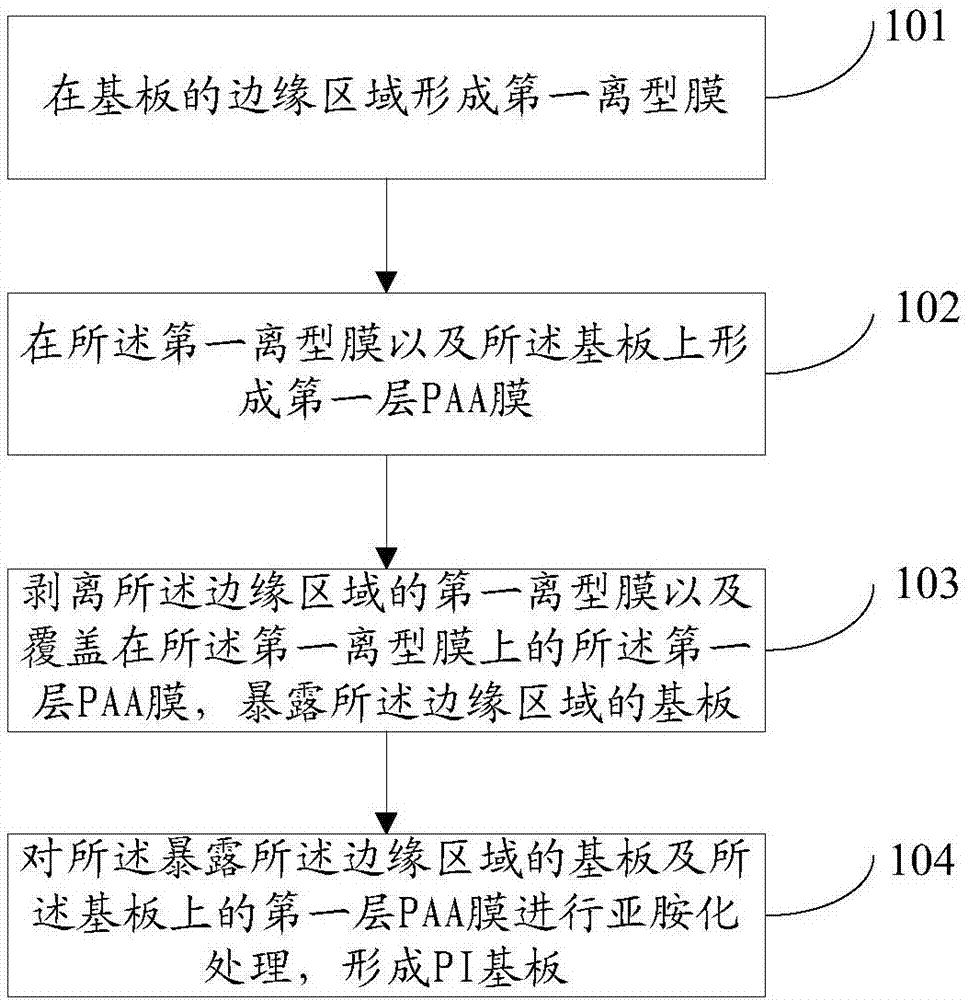

[0044] refer to figure 1 , which shows a flowchart of a method for preparing a PI substrate according to Embodiment 1 of the present invention.

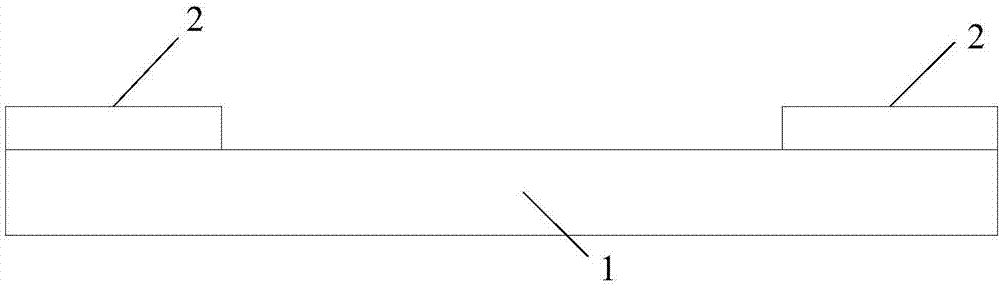

[0045] Step 101: forming a first release film on the edge region of the substrate, such as figure 2 shown.

[0046] A first release film 2 is formed on the edge region of the substrate 1, and the first release film 2 adopts a low-adhesion adhesive material, which is resistant to N-methyl-2-pyrrolidone (N-methyl-2-pyrrolidone, NMP) Solvent attack, and has heat resistance stability above 100°C.

[0047] The substrate can be formed of a transparent glass material whose main component is silicon dioxide. The material forming the substrate is not limited to the transparent glass material, and can also be a transparent plastic material. The substrate is preferably a glass substrate or a rigid substrate.

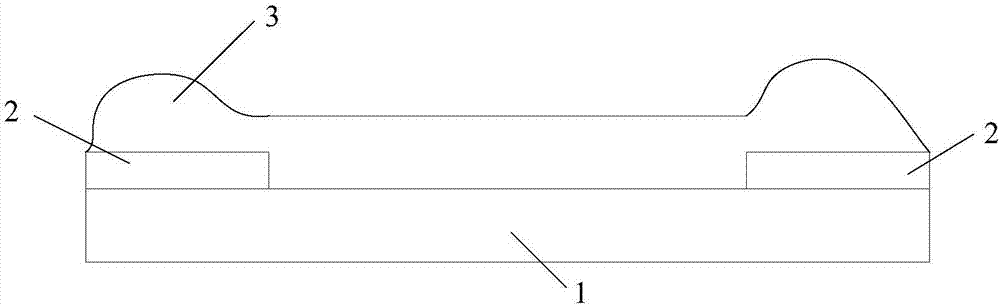

[0048] Step 102: Form a first layer of polyamic acid PAA film 3 on the first release film 2 and the substrate 1, such as image 3 s...

Embodiment 2

[0055] refer to Image 6 , which shows a flowchart of a method for preparing a PI substrate according to Embodiment 2 of the present invention.

[0056]Step 601: Form a first release film on the edge area of the substrate.

[0057] The first release film adopts a low-adhesive adhesive material, which is resistant to erosion by N-methyl-2-pyrrolidone (NMP) solvents, and has a heat-resistant stability above 100°C. Since polyimide can be resistant to erosion and reaction, the first release film material includes at least one of polyimide and polypropylene.

[0058] The width of the first release film can be set according to actual needs, which is not specifically limited in the present invention, and the width of the first release film is preferably 10 mm.

[0059] Step 602: forming a first layer of PAA film on the first release film and the substrate.

[0060] Coating a PAA film on the first release film and the substrate; drying the PAA film at high temperature to form a h...

Embodiment 3

[0082] refer to figure 2 , which shows a structural block diagram of a PI substrate according to Embodiment 3 of the present invention.

[0083] a substrate comprising a central region and an edge region;

[0084] A first layer of PAA film, the first layer of PAA film is formed in the central area of the substrate, wherein the flatness of the first layer of PAA film satisfies a preset condition.

[0085] The preset condition refers to that the flatness and thickness of the first PAA film are uniform.

[0086] Preferably, the PI substrate further includes: an inorganic layer covering the edge region of the substrate and the first layer of PAA film.

[0087] a second PAA film formed on the inorganic layer in the central region of the substrate.

[0088] In this embodiment, by forming a first release film in the edge area of the substrate; forming a first layer of PAA film on the first release film and the substrate; peeling off the first release film in the edge area and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com