Full-section multi-functional channel concrete lining machine

A full-section, multi-functional technology, applied in artificial waterways, water conservancy projects, buildings, etc., can solve problems such as unbalanced lining thickness, low degree of mechanization and work efficiency, and complex structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings.

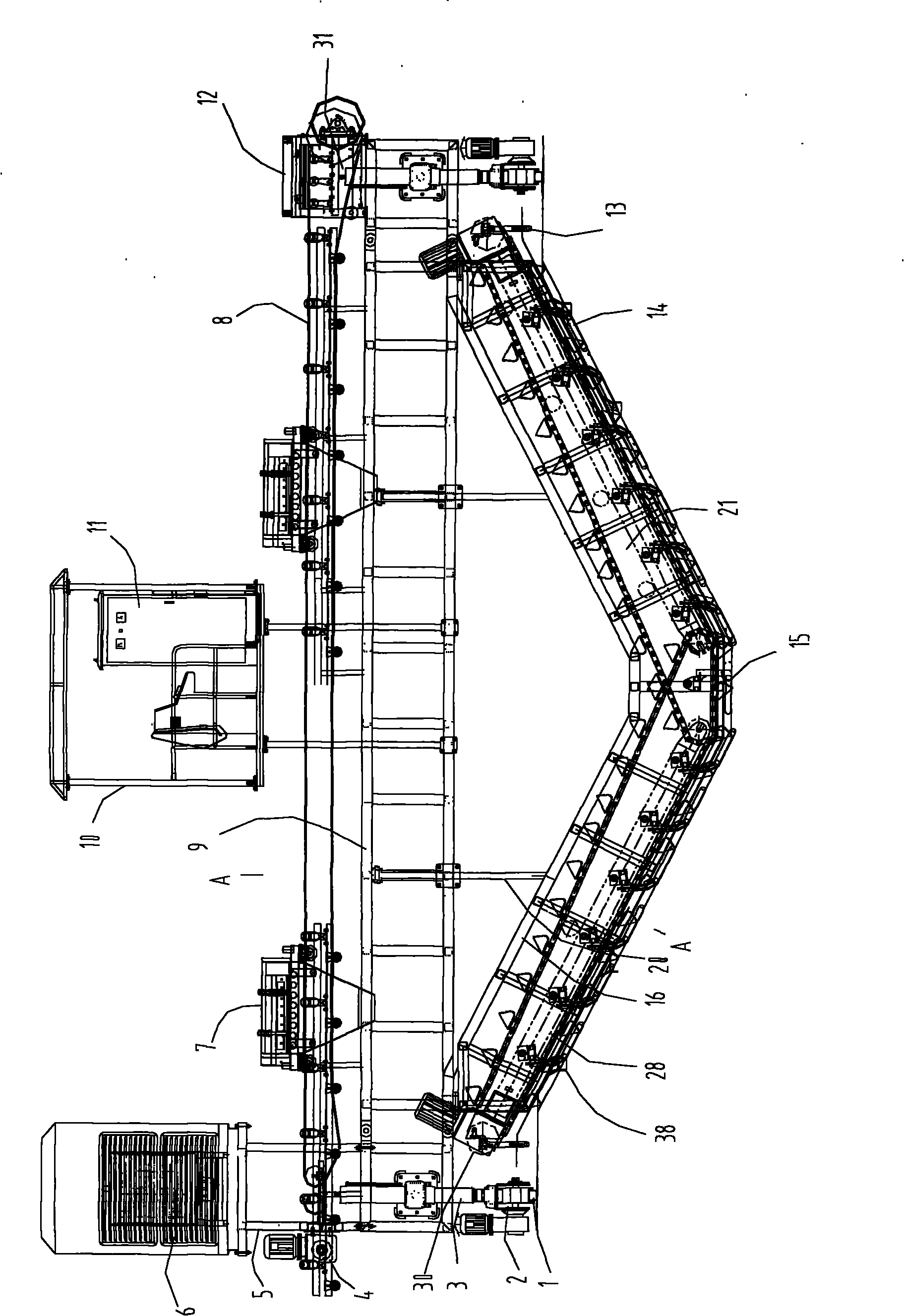

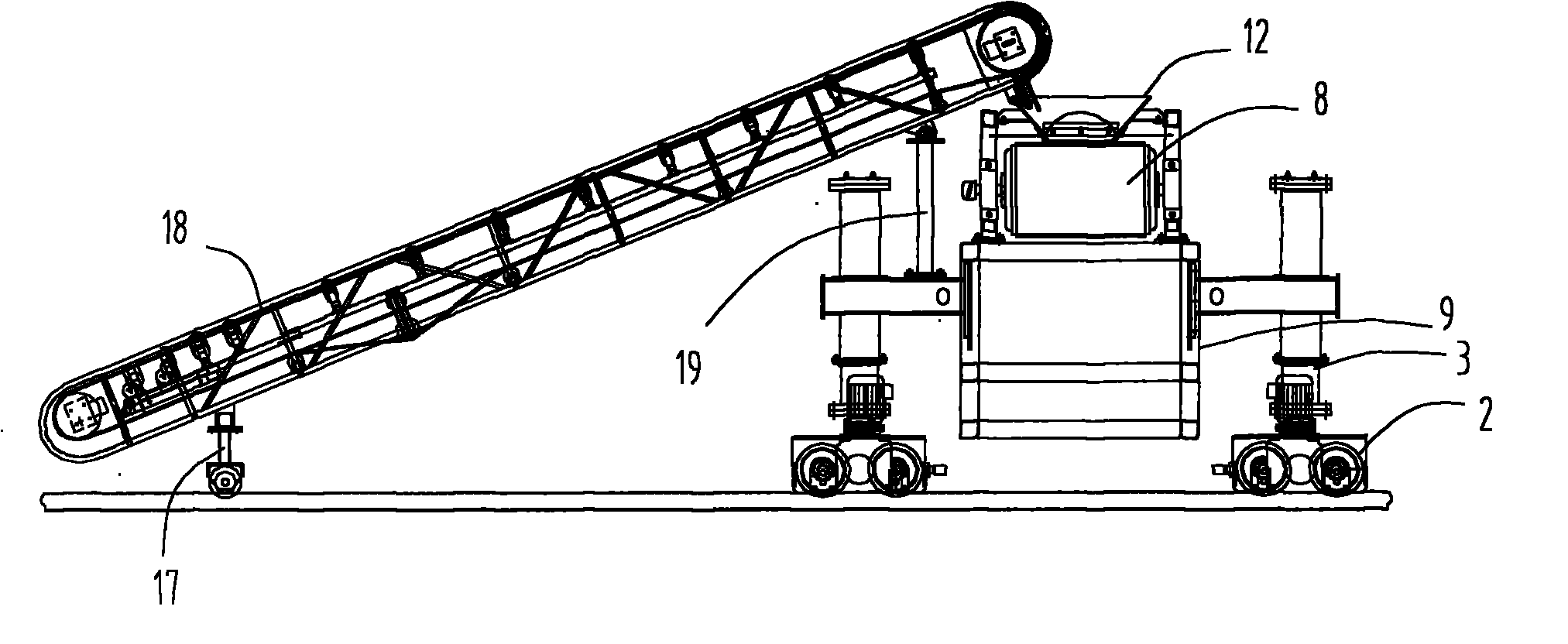

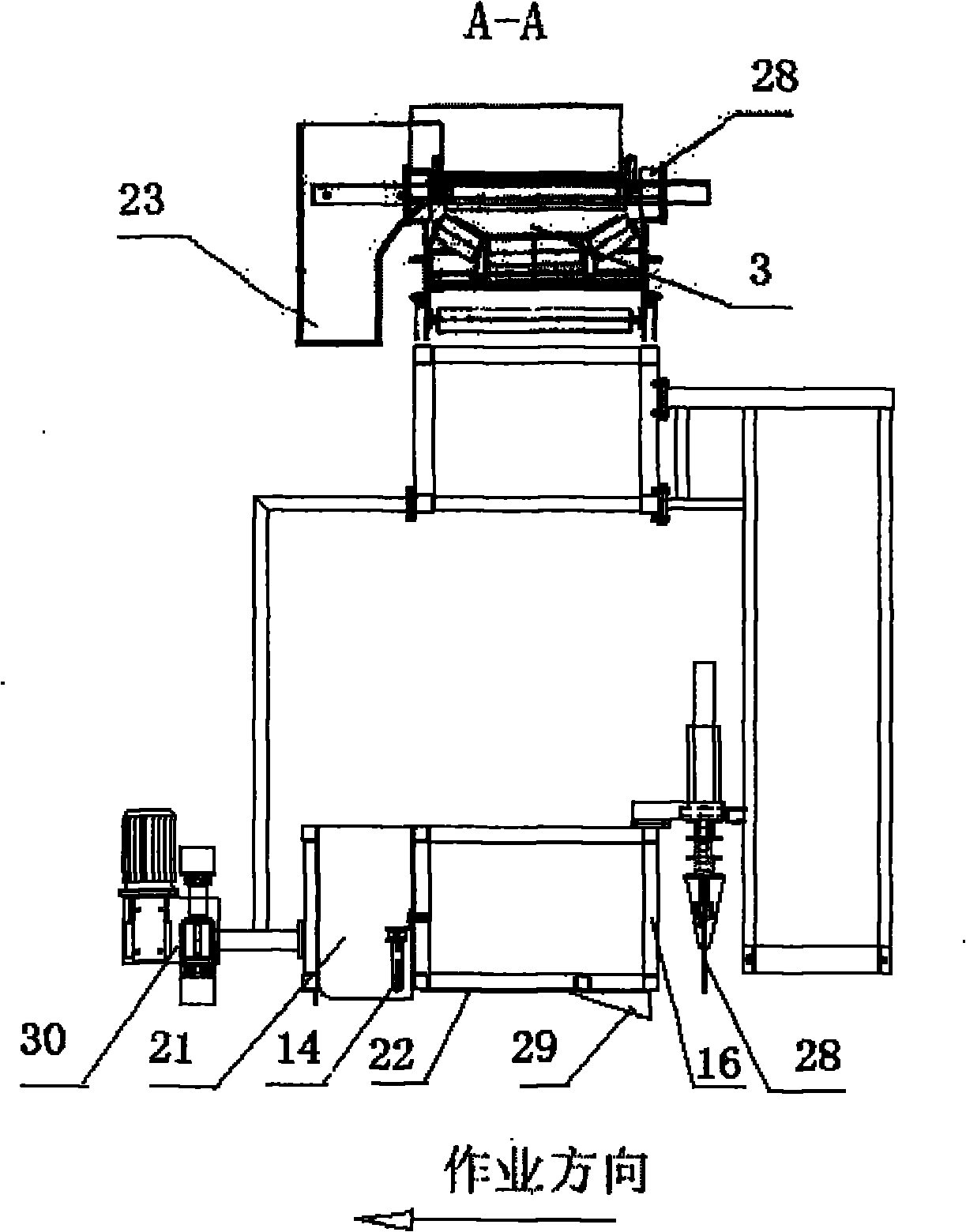

[0024] Such as figure 1 As shown, the present invention includes a main frame 9, a walking system, a complete machine lifting device, an automatic alignment system, a feeding system, a material distribution system, a vibrating scraping and compacting system, a full-section channel trimming system 30, a split forming system, Operating table, automatic control system, cleaning system 31, power system, full-section channel trimming system 30 includes full-section channel base surface trimming and forming device and continuously variable channel shoulder milling forming device 38, split forming system includes full-section transverse Slit forming device 28 and full-section longitudinal slit forming device 29.

[0025] distribution system such as figure 1 , 3 As shown, the main frame 9 spans the channel, the main frame 9 is equipped with a material distribution...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com