Semiconductor silicon-based optical waveguide device and preparation method thereof

A silicon-based optical waveguide and semiconductor technology, used in optical waveguides, optical components, light guides, etc., can solve the problem of high dependence on substrate quality, achieve flexible design and manufacturing, broad application prospects, yield and integration. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] According to a first aspect of the present invention, the present invention provides a method for preparing a semiconductor silicon-based optical waveguide device, comprising the following steps:

[0036] (a) Deposit the bottom cladding layer on the non-polished surface of the single-sided polished silicon wafer;

[0037] (b) sequentially stacking and depositing the lower cladding layer, core layer and mask layer on the polished surface of the single-sided polished silicon wafer;

[0038] (c) forming a waveguide channel after etching the core layer and removing the mask layer;

[0039] (d) Depositing an upper cladding layer on the etched core layer to obtain a semiconductor silicon-based optical waveguide device;

[0040] Preferably, the mask layer is a metal mask layer.

[0041] The preparation method of the semiconductor silicon-based optical waveguide device provided by the present invention uses semiconductor silicon as the substrate material, has good compatibili...

Embodiment 1

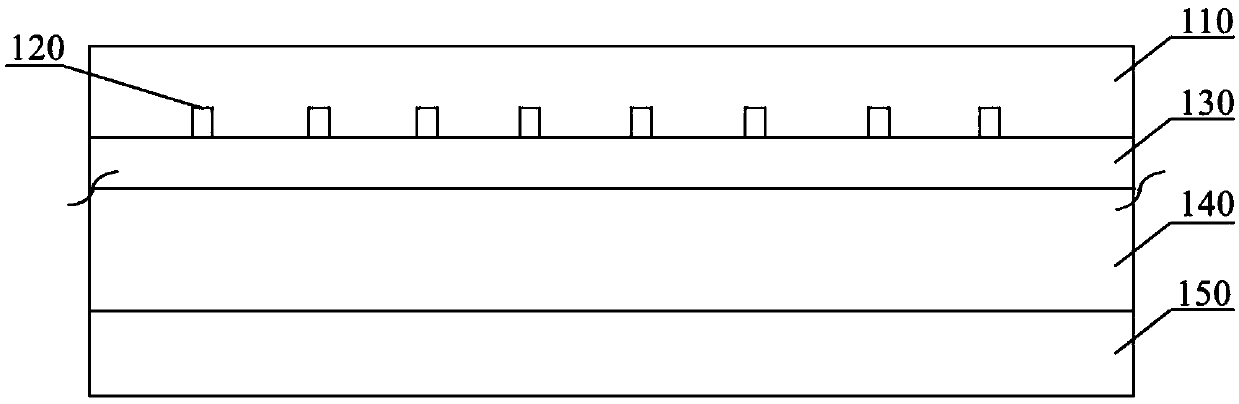

[0104] This embodiment provides a semiconductor silicon-based optical waveguide device, the structure of which is as follows figure 1 As shown, there are bottom cladding layer 150 , single-sided polished silicon wafer 140 , lower cladding layer 130 , waveguide channel 120 and upper cladding layer 110 from bottom to top. Its preparation method comprises the following steps:

[0105] (a) Select a general-purpose single-sided polished silicon wafer 140 for cleaning before deposition, and then use PECVD equipment to deposit a bottom cladding layer 150 on the non-polished surface of the single-sided polished silicon wafer 140. The bottom cladding layer 150 is boron-phosphorus-doped Silicon dioxide, wherein the mass ratio of borane to silicon dioxide is 1.7:100, the mass ratio of phosphine to silicon dioxide is 1.9:100, and the thickness is 18 μm.

[0106] (b) Use megasonic dilute hydrofluoric acid solution and SC-1 solution to clean the single-sided polished silicon wafer 140, and...

Embodiment 2

[0111] This embodiment provides a semiconductor silicon-based optical waveguide device. The difference between the preparation method of this embodiment and Embodiment 1 is that the thickness of the core layer is 5.5 μm, and 8 channels (5.5 μm ×5.5μm cross-sectional area) splitter optical waveguide device.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com