Pole piece, preparation method thereof and battery

A pole piece and positive pole piece technology, which is applied in the field of pole piece and its preparation, can solve the problems of different pole piece current density, uneven pole piece thickness, and increased battery resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

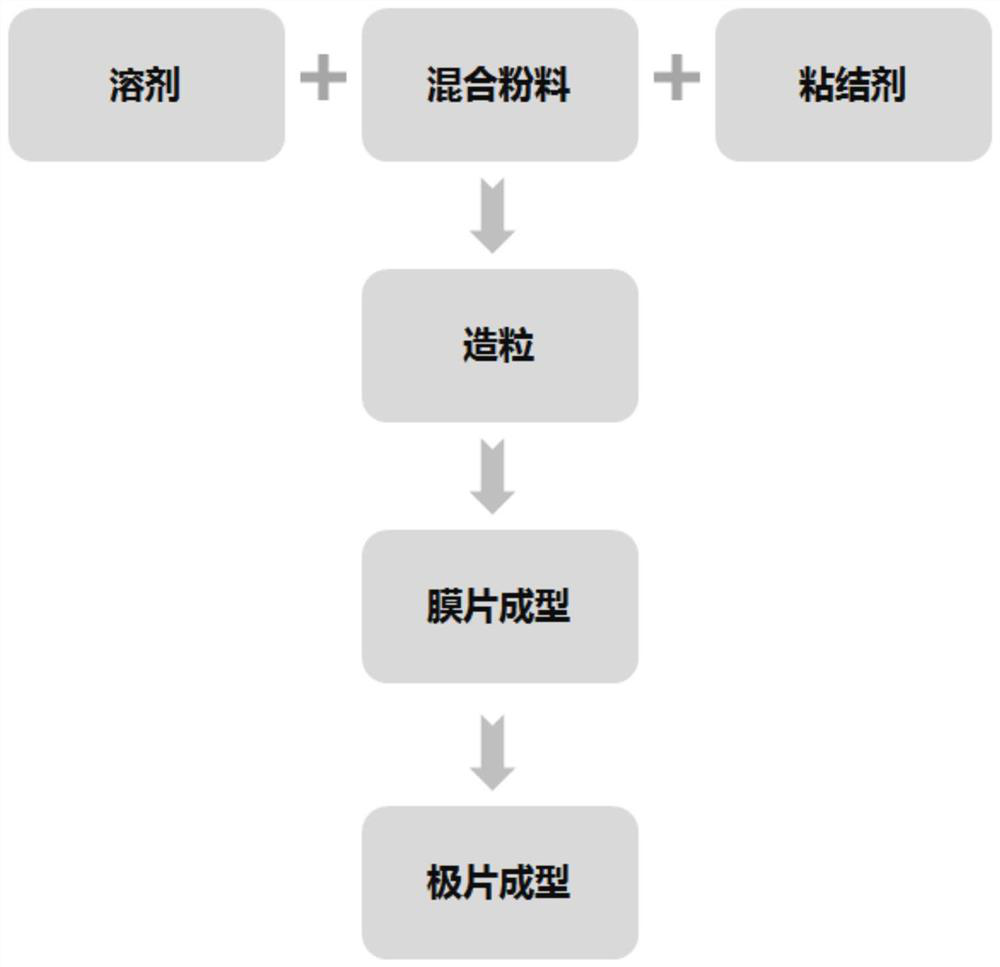

[0059] The present embodiment is prepared according to the following method:

[0060] (1) 78wt% LiFePO 4 Fully mix with 2wt% conductive carbon, then fully mix with 3% polytetrafluoroethylene binder, 17wt% ethanol / water (1 / 2) mixed solvent, use a high-speed granulator to mix and granulate at a speed of 1000rpm for 5min, Prepare mixed particles;

[0061] (2) The mixed particles described in step (1) are used with a three-roll film laminator (0.1 mm between roll 1 and roll 2, and 0.08 mm between roll 2 and roll 3) at a temperature of 25 ° C with a speed of 3 r / min. The aluminum foil of the current collector is formed into a membrane, and then baked in an oven at 120° C. for 8 hours, and then cut into positive electrodes after baking.

[0062] The schematic flow chart of the preparation method of this embodiment is as follows figure 1 shown.

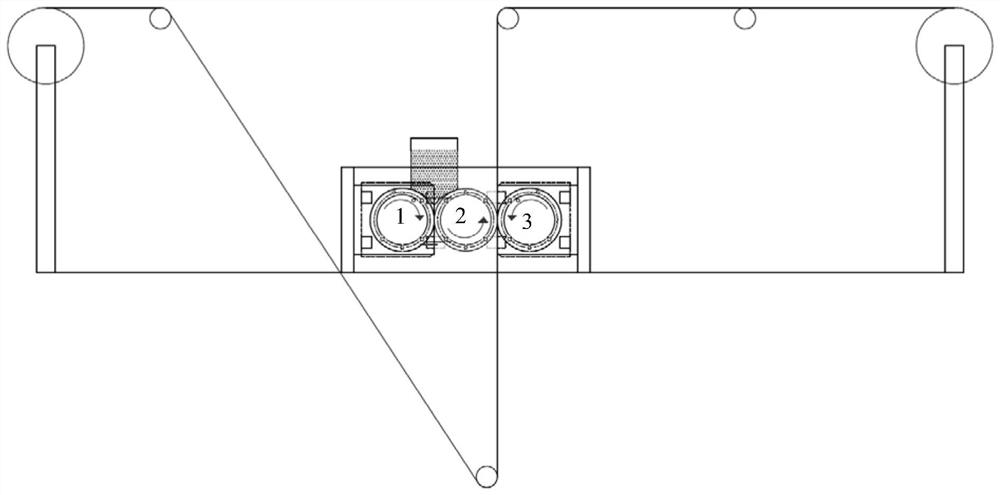

[0063] The schematic diagram of the laminating machine of this embodiment is as figure 2 As shown, the roll 1 and roll 2 of the clamp...

Embodiment 2

[0066] The present embodiment is prepared according to the following method:

[0067] (1) with the step 1 of embodiment 1

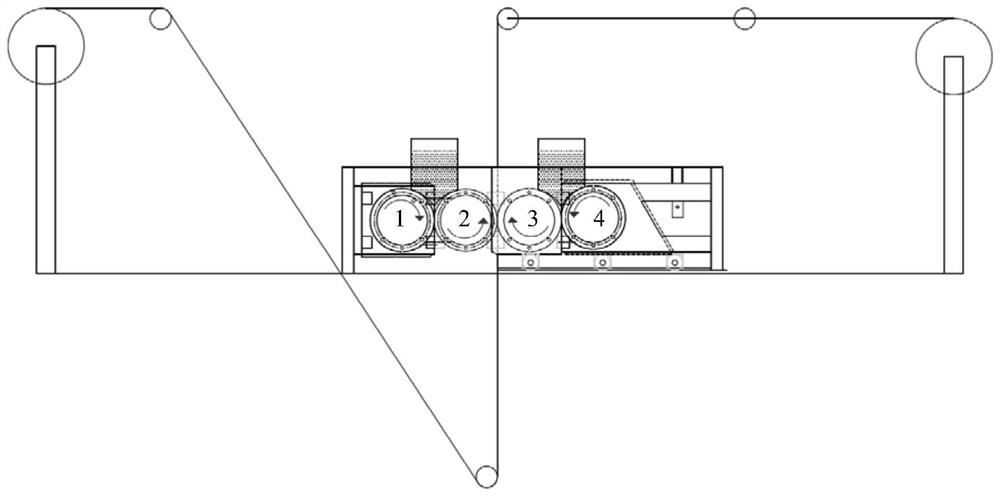

[0068] (2) The mixed particles described in step (1) are used in a four-roll laminating machine (the distance between the roller 1 and the roller 2 and the roller 3 and the roller 4 is 0.1 mm, and the distance between the roller 2 and the roller 3 is 0.1 mm), at 25 °C at a roller speed of 3r / min to form a membrane with the aluminum foil of the current collector, and then bake in an oven at 120 °C for 8 hours, and then bake and cut to obtain the positive electrode sheet.

[0069] The schematic diagram of the laminating machine of this embodiment is as image 3 As shown, roll 1 and roll 2 of the clamping machine pre-press the mixed particles, roll 3 and roll 4 also pre-press the mixed particles, and roll 2 and roll 3 combine the pre-pressed mixed particles with the current collector Co-membrane.

[0070] The test results of the positive electrode sheet p...

Embodiment 3

[0072] The present embodiment is prepared according to the following method:

[0073] (1) Fully mix 95wt% lithium iron phosphate and 2.5wt% conductive carbon, then fully mix with 2.5% polytetrafluoroethylene binder, use a high-speed granulator to mix and granulate at a speed of 200rpm for 1min, and prepare a mixed particles;

[0074] (2) Use the same four-roll mold clamping machine as in Example 2 to form the positive electrode sheet with the aluminum foil of the current collector at a temperature of 15 ° C at a temperature of 15 ° C, and then place it in a 200 ° C Bake in an oven for 28 hours to obtain a positive electrode sheet.

[0075] The test results of the positive electrode sheet prepared in this example are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com