Assembly line equipment for producing hard PVC (polyvinyl chloride) sheets

An assembly line and sheet technology, used in applications, household appliances, other household appliances, etc., can solve the problems of many bubbles, narrow processing range, large surface flow lines, etc., to achieve uniform temperature, improve lateral shrinkage, and thickness consistency. improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

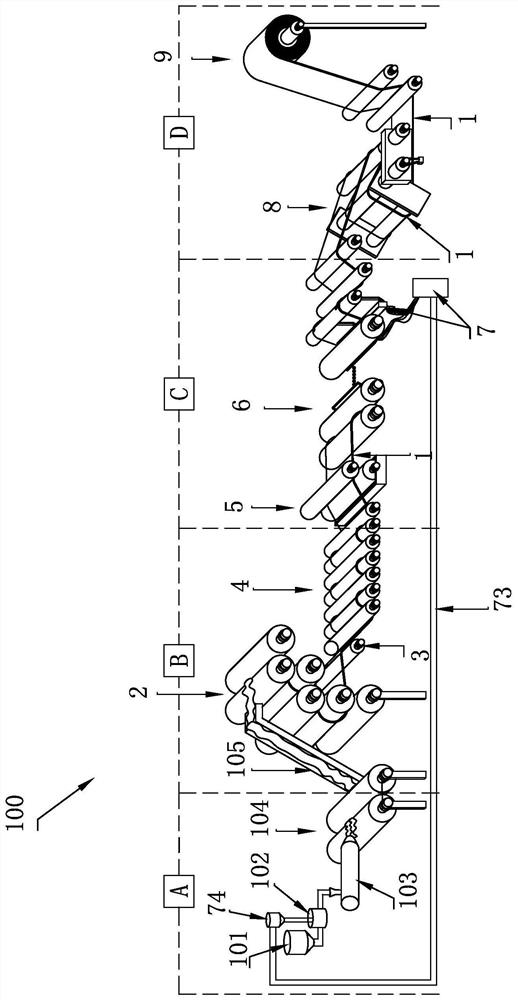

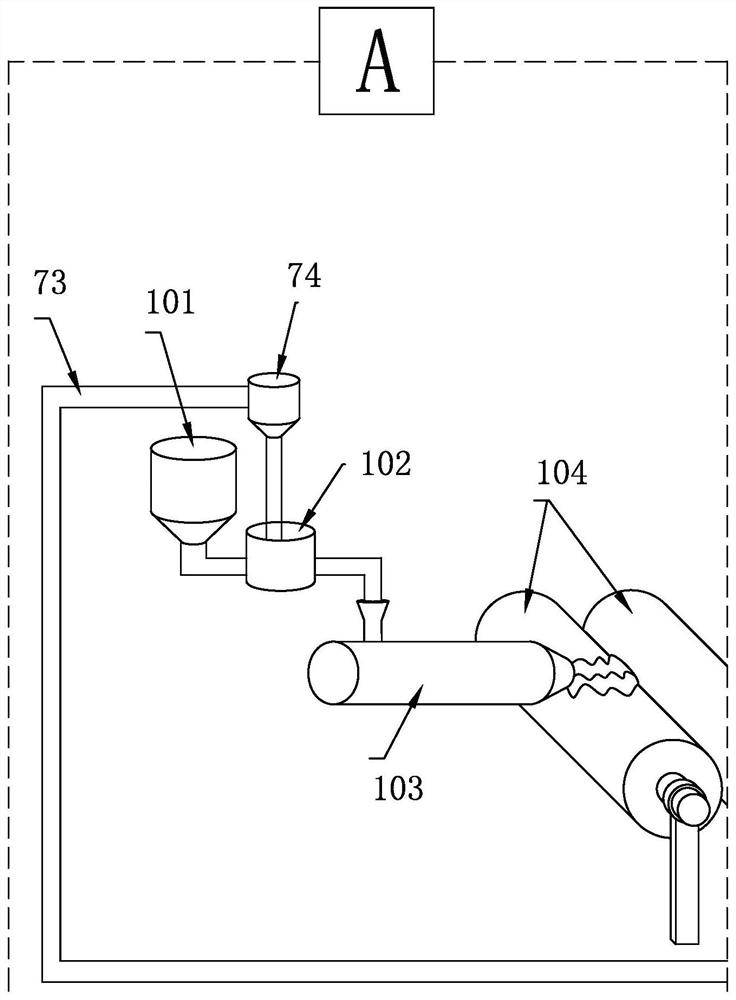

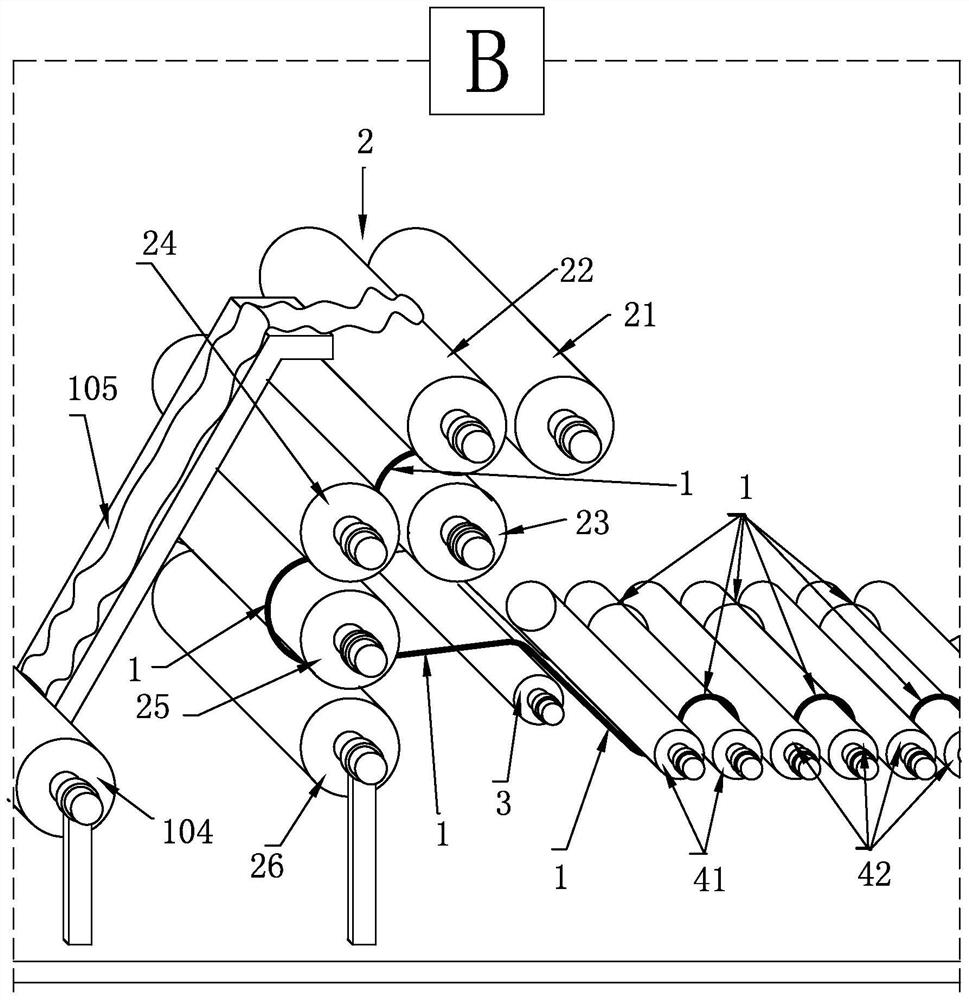

[0028] Such as figure 1 As shown in -5, the assembly line equipment used to produce rigid PVC sheets (hereinafter also referred to as sheets) of the present invention includes from front to back successively installed on the frame: high-speed pot 101, cooling pot 102, extruder 103. Open mill 104, feeder 105, calender 2, lead-away parts, initial cooling zone 4, rigidity improvement section 5, room temperature heat preservation zone 6, edge material online crushing and recovery device 7, sheet tension adjustment device 8, Finished sheet material winding device 9 and PLC automatic control and monitoring system (included in the main control circuit of the assembly line equipment) and other process equipment or process sections (Note: for the convenience of viewing the figure, the components of the above-mentioned process equipment or process sections The rack supporting these components is not shown).

[0029] The assembly line production equipment 100 of the present invention ha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com