Method for increasing conversion efficiency of thin-film solar cell

A solar cell and conversion efficiency technology, applied in circuits, electrical components, gaseous chemical plating, etc., can solve the problem that the surface of the N-type buffer layer cannot be completely covered, the conversion efficiency of thin-film solar cells is restricted, and the surface step coverage of the film layer is poor, etc. problem, to achieve the effect of improving photoelectric conversion efficiency, facilitating large-scale production, and good thickness consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to further understand the content of the present invention, the content of the invention and specific embodiments are specifically described below:

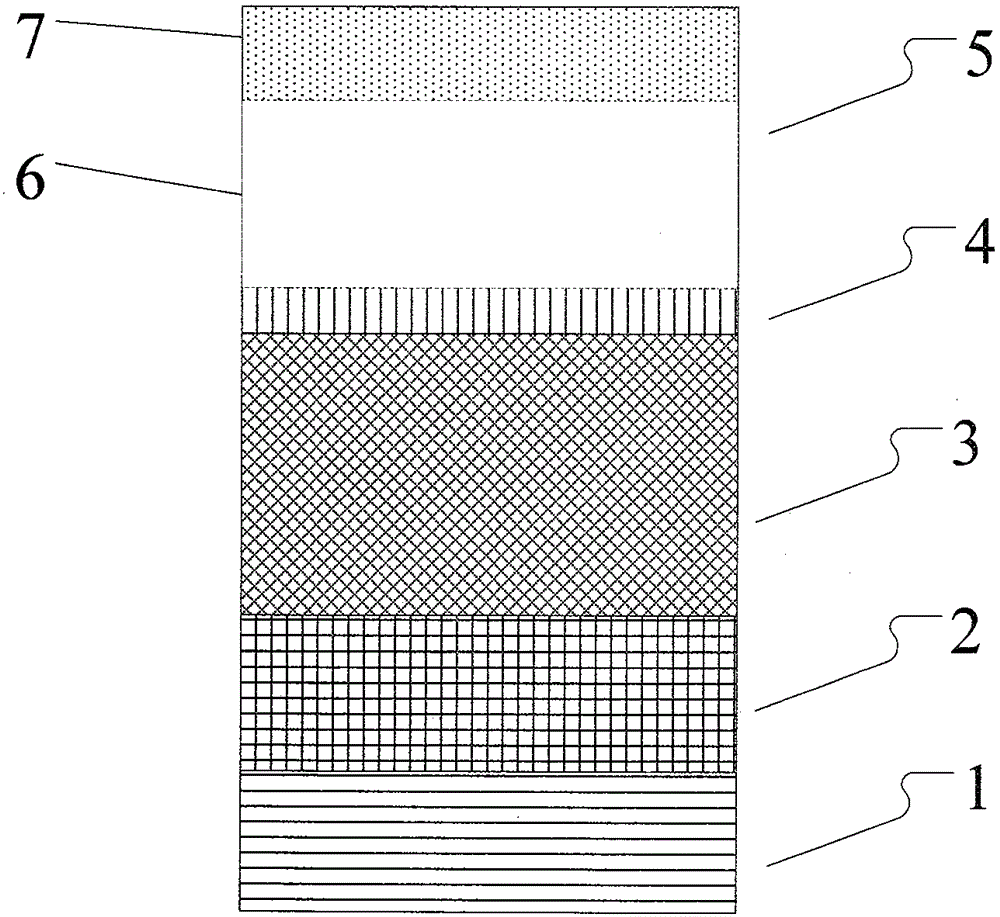

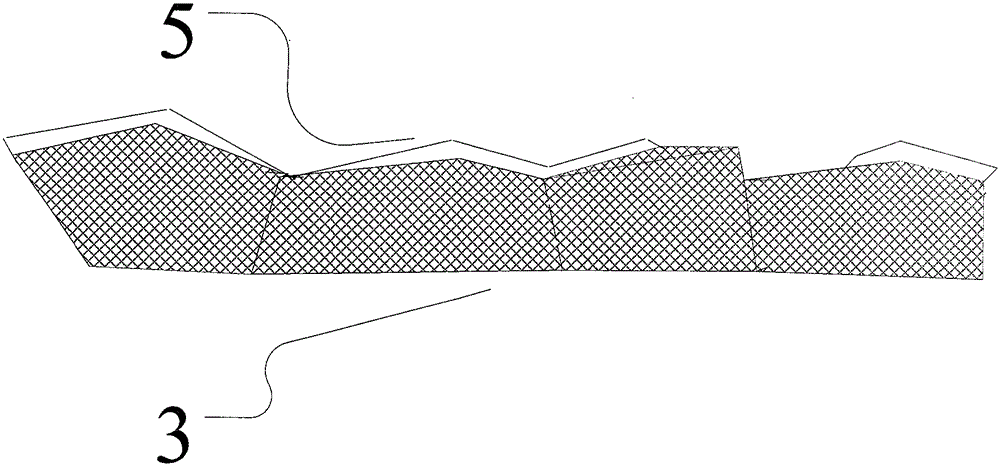

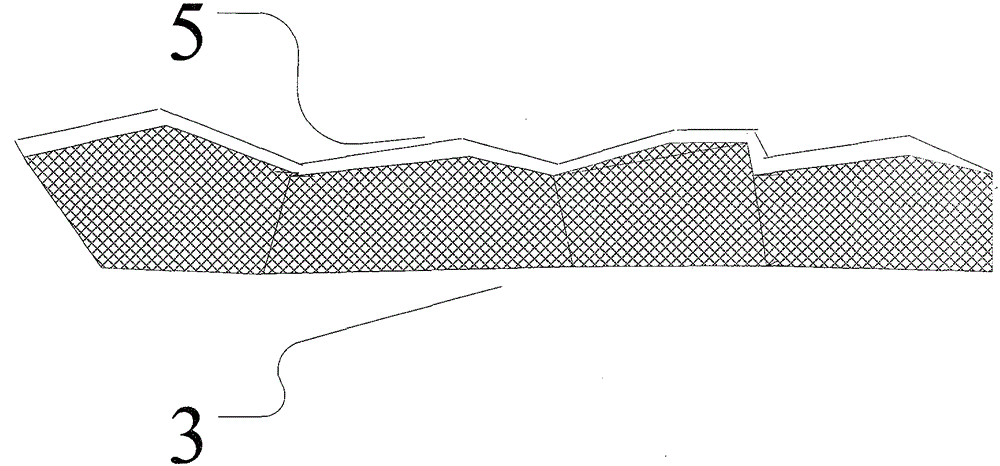

[0024] Such as figure 1 As shown, the thin-film solar cell includes a substrate 1, a back electrode 2, a P-type light absorbing layer 3, an N-type buffer layer 4 and a window layer 5, and the above-mentioned back electrode 2, P-type light absorbing layer 3, and N-type buffer layer 4 Depositing the window layer 5 and the window layer 5 on the substrate 1 sequentially is a method for improving the conversion efficiency of thin-film solar cells. Before processing the window layer 5, the semi-finished cell sheet to be processed is prepared first.

[0025] The production of semi-finished batteries can be processed according to the following methods according to the choice of glass or stainless steel for the substrate material:

[0026]When selecting glass as the substrate 1, first plate the back electrode 2 of the mol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com