Resin composition, prepreg containing same and dielectric substrate for antenna

A resin composition and prepreg technology, applied in the direction of synthetic resin layered products, layered products, metal layered products, etc., can solve thickness deviation, thickness consistency, poor dielectric constant consistency, different resin content, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-7

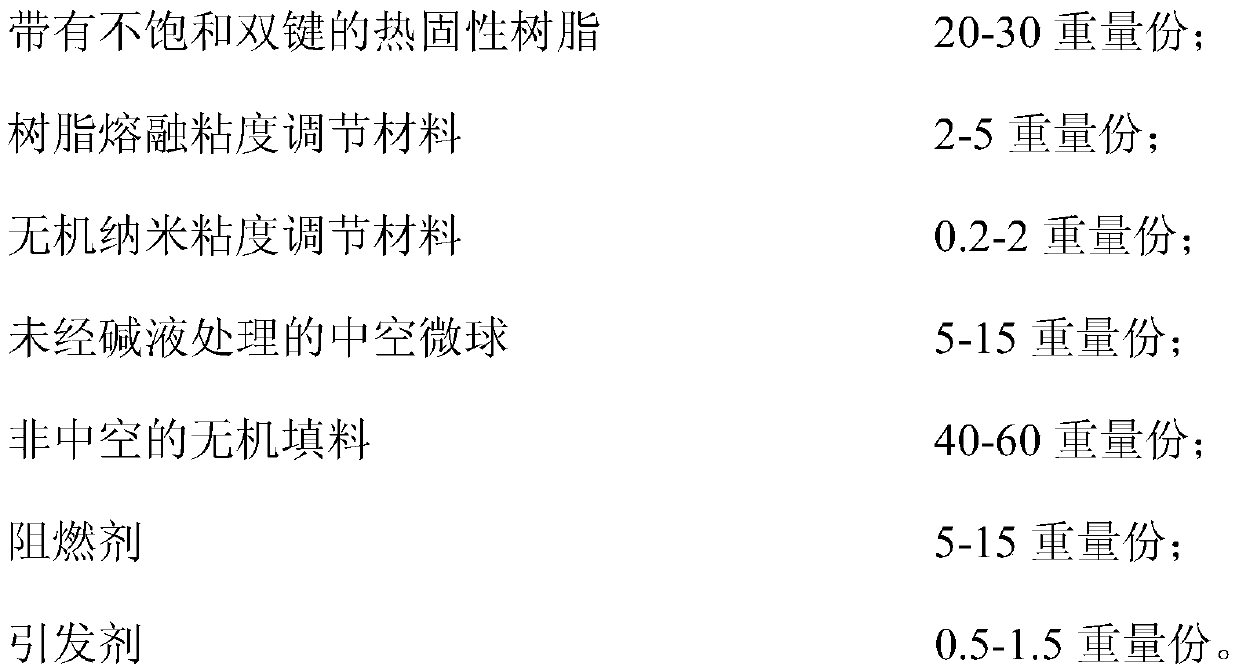

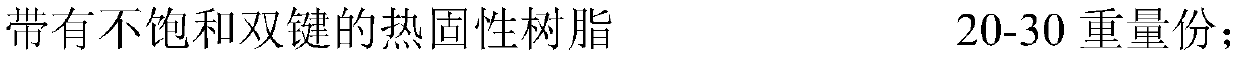

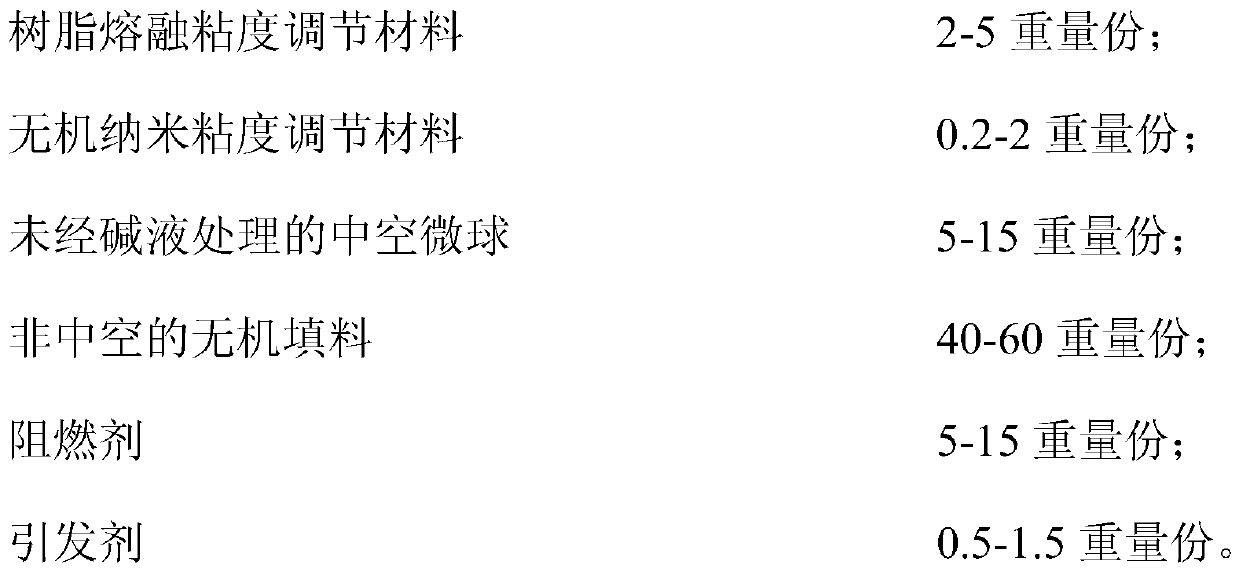

[0073] Prepare the resin composition according to the components shown in Table 2 (the unit of raw material dosage is parts by weight), and make a copper-clad laminate sample according to the following production method:

[0074] (1) Dissolve and mix the components in the formula quantity into the reaction kettle, and dilute to an appropriate viscosity with a solvent, stir and mix evenly to obtain the resin glue.

[0075] (2) Soak the glass fiber cloth with the resin glue, dry the solvent and bake until it is semi-cured, then stack multiple sheets, press and cover a piece of copper foil on the top and bottom, and put it into a press for curing to obtain a copper-clad laminate. , the curing temperature is 150-300°C, and the curing pressure is 25-70kg / cm 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com