3D (Three-Dimensional) glass metal complex, preparation method thereof and electronic product

A glass-metal, electronic product technology, applied in the direction of electrical equipment shell/cabinet/drawer, sub-station equipment, electrical components, etc., can solve the problems of not tight combination, increased risk of broken screen, no stepless combination, etc. Product yield, reduce the risk of broken screen, reduce the effect of production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

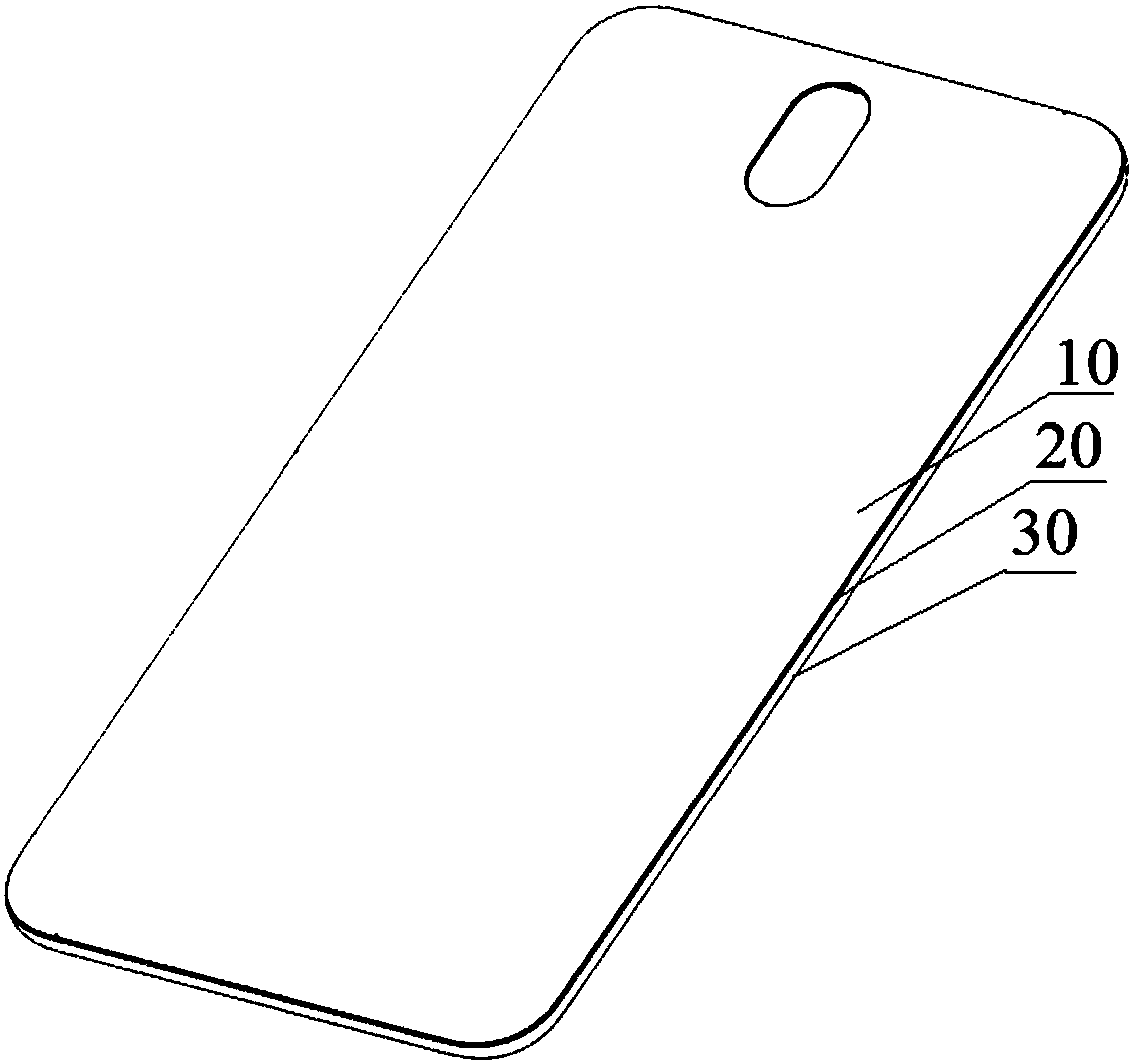

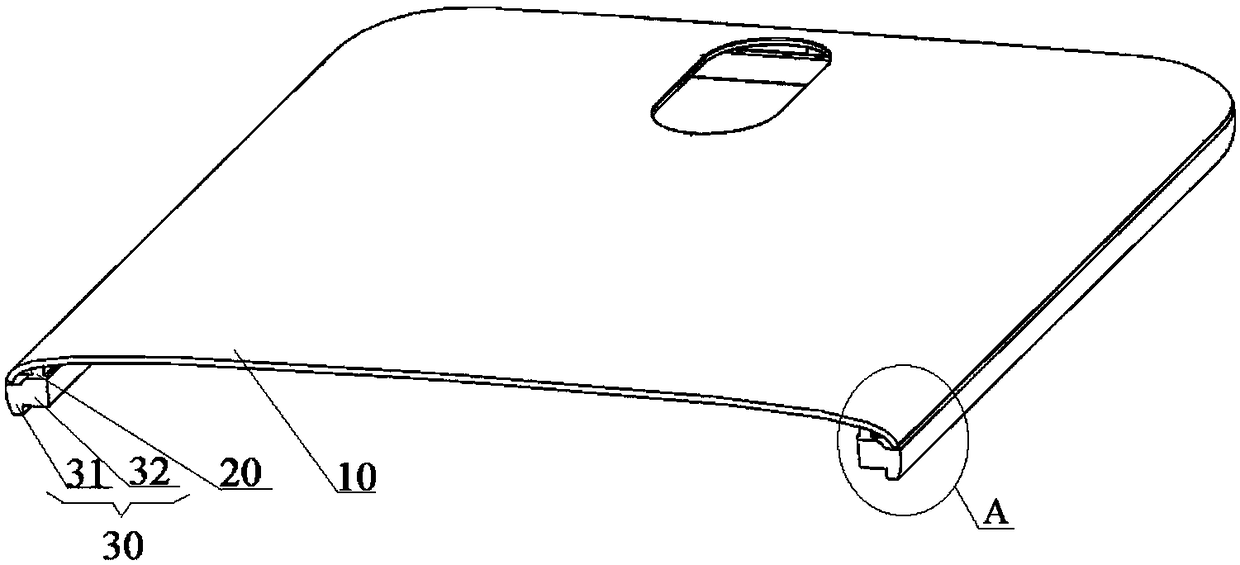

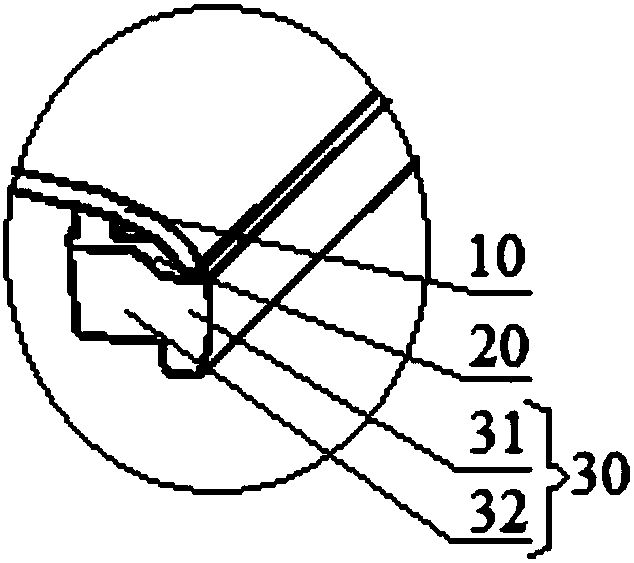

[0030] In a second aspect, the present invention provides a method for preparing a 3D glass-metal composite, the method comprising: (1) providing a 3D glass cover plate 10 (such as Figure 4 shown), and coat the activator on the side surface of the 3D glass cover plate 10, and dry; (2) provide a metal frame prefabricated body 30' (such as Figure 5 As shown), the metal frame prefabricated body 30' is reserved with respect to the final structure of the metal frame 30 with a reserved portion 33 extending outward along the outer circumference of the metal frame 30; (3) the 3D obtained in step (1) The glass cover plate 10 and the metal frame prefabricated body 30′ are placed in an injection mold, and injection plastic is filled between the side surface of the 3D glass cover plate 10 and the upper surface of the metal frame prefabricated body 30, and injection molding is performed to obtain a 3D glass metal Composite preforms (such as Figure 6 shown); (4) cutting the 3D glass-met...

Embodiment 1

[0086](1) Roughen the side surface of the 3D glass cover plate prepared above, and use a 70T screen to screen-print UV ink on the side surface of the aforementioned 3D glass cover plate. Under the machine, expose for 3 minutes; use a 380-mesh screen to screen-print the activator on the UV ink, the thickness of the screen printing of the activator is 10 μm, and then put the glass in a tunnel dryer at 90°C to dry for 90 minutes; the activator is a polyurethane system , including polyurethane, acetone and ethylenediamine, based on the weight of the activator, the contents of polyurethane, acetone and ethylenediamine are respectively 88% by weight, 8% by weight and 4% by weight.

[0087] (2) The aluminum alloy is processed and shaped, polished, chemically polished, sand blasted, anodized, microporous, and film-coated in sequence to obtain an aluminum alloy frame prefabricated body (refer to the above description for the structure, and the width of the reserved part is 1.5 mm), and...

Embodiment 2

[0091] (1) Roughen the side surface of the 3D glass cover plate prepared above, use a 70T screen to screen-print thermosetting ink on the side surface of the 3D glass cover plate, the thickness of the thermosetting ink is 15 μm, and then Dry in an oven for 90 minutes; use a 300-mesh screen to screen-print the activator on the thermosetting ink, the thickness of the screen-printed activator is 15 μm, and then put the glass in a tunnel dryer at 80°C to dry for 110 minutes; the activator is polyurethane The system includes polyurethane, ethyl acetate and ethylene glycol. Based on the weight of the activator, the contents of polyurethane, ethyl acetate and ethylene glycol are respectively 85 wt%, 10 wt% and 5 wt%.

[0092] (2) The aluminum alloy is processed and shaped, polished, chemically polished, sand blasted, anodized, microporous, and film-coated in sequence to obtain an aluminum alloy frame prefabricated body (refer to the above description for the structure, and the width o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com