Copper sulfide anode and preparation method thereof

A copper sulfide and positive electrode technology, applied in battery electrodes, electrical components, circuits, etc., can solve the problems of unfavorable large-area preparation, long preparation cycle, and high equipment requirements, so as to improve cycle stability, avoid long-term reaction, and conduction performance Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

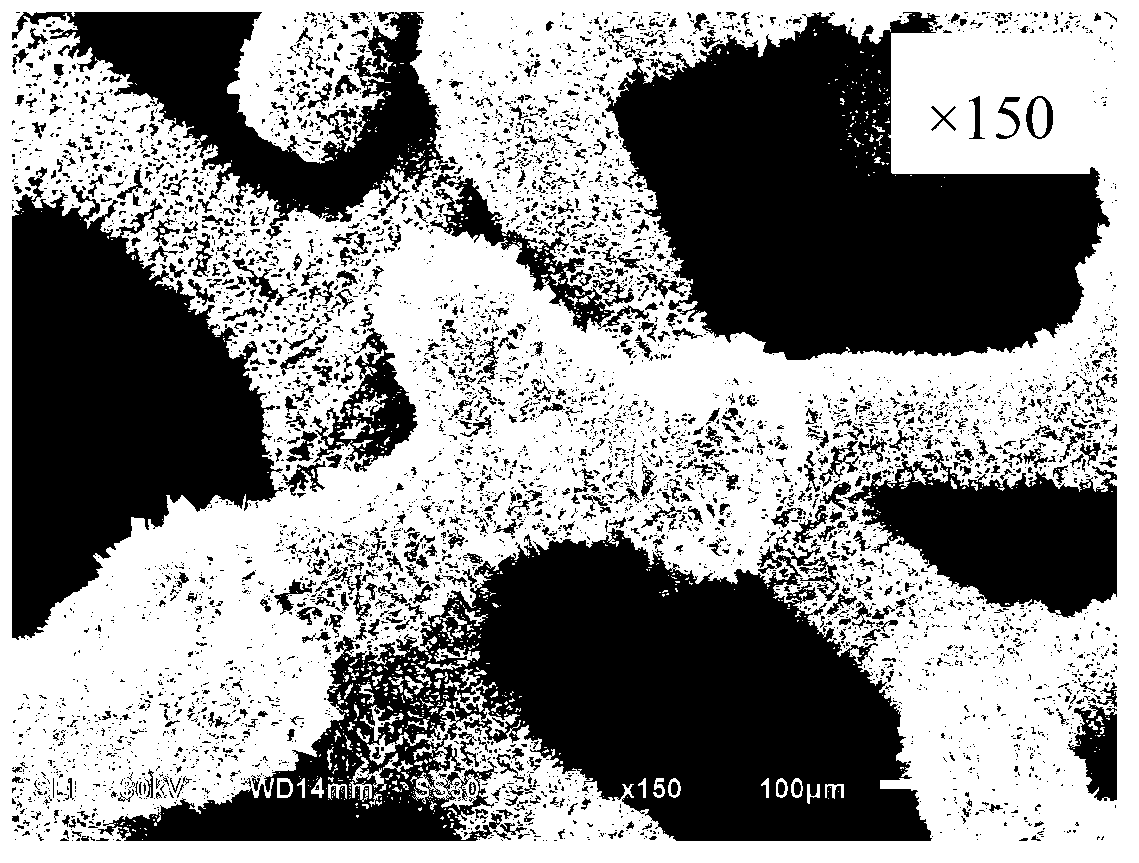

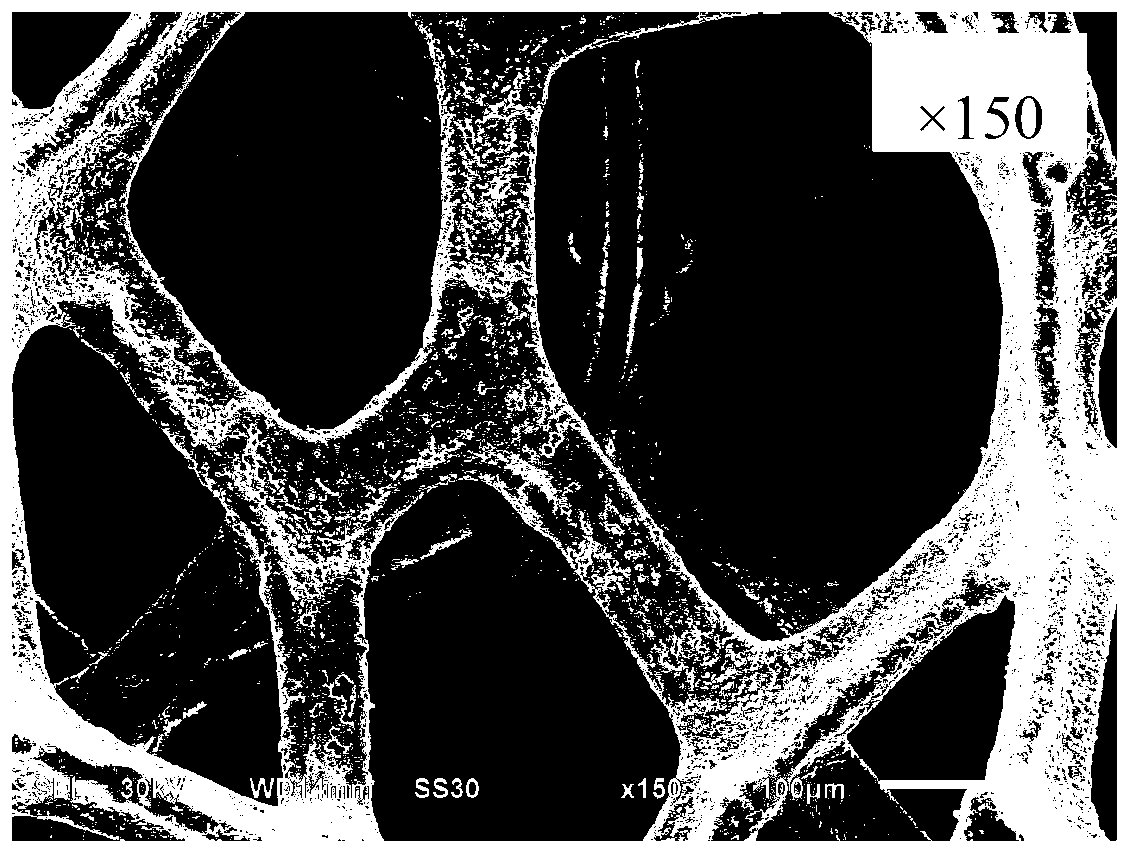

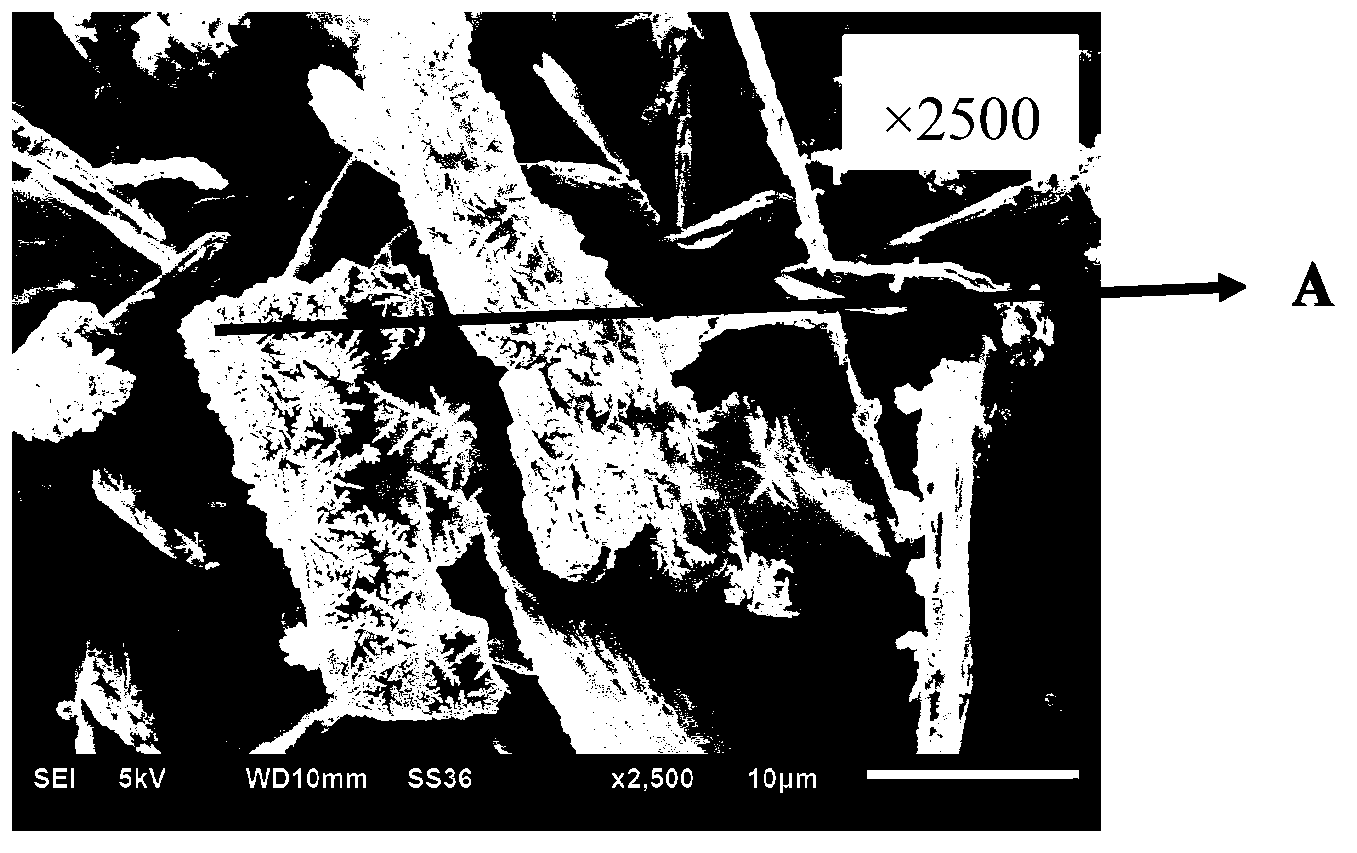

[0049] Preparation of copper sulfide integrated positive electrode: cut the foamed copper with a porosity of 94%, a pore diameter of 0.2mm, and a thickness of 2.5mm into discs with a diameter of 10mm, and press it to 0.2mm with a tablet press, and in 1mol / L HCl Use ultrasonic cleaning in the solution for 15 minutes, then ultrasonic cleaning in acetone solution for 15 minutes, and ultrasonic cleaning in deionized water for 10 minutes. The sulfur load is 0.03g / cm 2 Prepare foamed copper and elemental sulfur, weigh 2.9 mg of elemental sulfur ground to 50 μm, cover the elemental sulfur evenly on the foamed copper, place it in a tube furnace, and under the protection of nitrogen flow, the gas flow rate is 1.5 L / min, the flow rate 20cm / min; keep warm at 155°C for 3h, then raise the temperature to 350°C, keep warm for 1h, synthesize lamellar copper sulfide on the foamed copper skeleton, and the copper sulfide on the sheet has a snowflake-like shape, that is, the positive electrode, t...

Embodiment 2

[0052] Preparation of copper sulfide integrated positive electrode: Cut the foamed copper with a porosity of 96%, a pore diameter of 0.15 mm, and a thickness of 2.7 mm into discs with a diameter of 10 mm, and press it to 0.3 mm with a tablet press. Use ultrasonic cleaning in HCl solution for 30 minutes, then ultrasonic cleaning in acetone solution for 30 minutes, and ultrasonic cleaning in deionized water for 15 minutes. According to the sulfur loading capacity of foamed copper is 0.18g / cm 2 Prepare foamed copper and elemental sulfur, weigh 17.5 mg of elemental sulfur ground to 10 μm, cover the elemental sulfur evenly on the foamed copper, place it in a tube furnace, and under the protection of argon gas flow, the gas flow rate is 0.1L / min. The flow rate is 2cm / min; heat preservation at 155°C for 8 hours, and the lamellar copper sulfide is synthesized on the foamed copper skeleton. The copper sulfide on the sheet has a hexagonal columnar shape, and the positive electrode is ob...

Embodiment 3

[0055] Preparation of copper sulfide integrated positive electrode: foamed copper with a porosity of 98%, a pore diameter of 0.1mm, and a thickness of 3mm is cut into a disc with a diameter of 10mm, pressed to 0.5mm with a tablet press, and placed in a 2mol / L HCl solution Use ultrasonic cleaning for 60 minutes, then ultrasonic cleaning in acetone solution for 60 minutes, ultrasonic cleaning in deionized water for 20 minutes, the power of ultrasonic wave is 100W, vacuum dry the cleaned foamed copper at 80°C for 40 minutes, and set aside; The amount is 0.3g / cm 2 Prepare foamed copper and elemental sulfur, weigh 29 mg of elemental sulfur ground to 100 μm, cover the elemental sulfur evenly on the foamed copper, place it in a tube furnace, and under the protection of an argon atmosphere, the gas flow rate is 5 L / min, and the flow rate is 60cm / min; heat preservation at 155°C for 2 hours, heat preservation at 250°C for 1 hour, synthesize sheet-like copper sulfide on the foamed copper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Sheet thickness | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com