Laser-welding fiber grating surface temperature sensor and packaging method thereof

A fiber grating, laser welding technology, applied in the direction of thermometers, thermometers, instruments, etc. with physical/chemical changes, can solve the problems affecting the natural thermal expansion of metal substrates and fiber gratings, easy creep and aging, fiber grating center wavelength shift, etc. problems, to achieve the effect of improving long-term reliability and stability, overcoming creep and aging, and reducing contact thermal resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with specific examples and accompanying drawings.

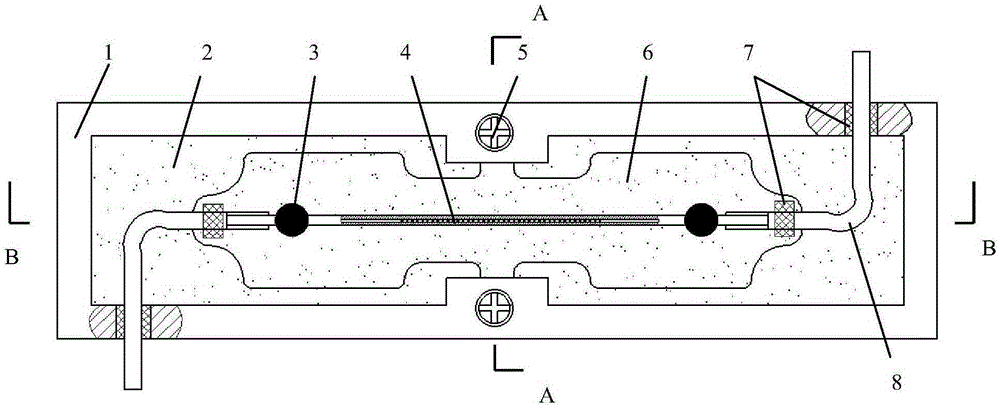

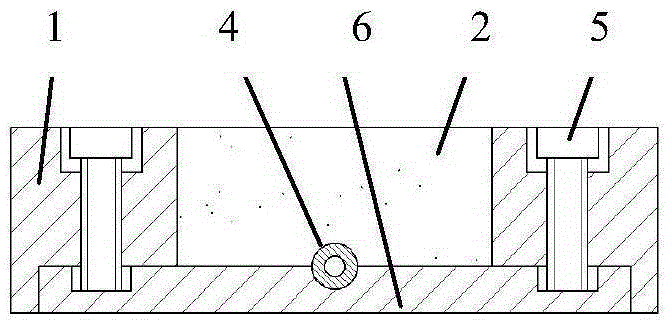

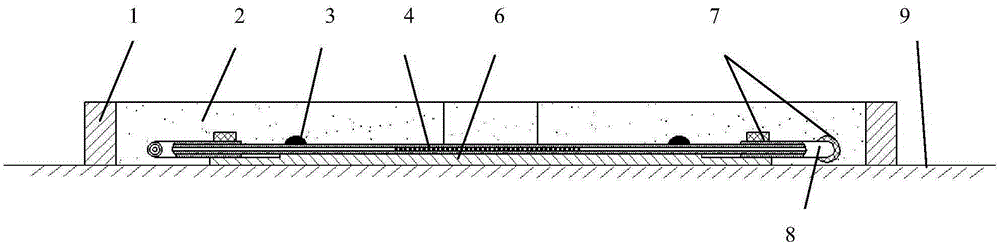

[0030] figure 1 It is a structural schematic diagram of an embodiment of the present invention, figure 2 for figure 1 A-A sectional view of, image 3 for figure 1 The B-B sectional view, Figure 4 for figure 1 The bottom view of a laser-welded fiber grating surface temperature sensor, comprising an optical fiber, a metal substrate 6 and a bottomless non-metallic frame 1; The signal transmission pigtail, the two ends of the fiber grating 4 coated with metal layer are fixed on the metal substrate 6 by laser welding, the signal transmission pigtail is covered with a protective fiber sleeve 8; the bottom of the non-metallic frame 1 and the metal The substrate 6 is fixed, and the non-metallic frame 1 is provided with a through hole for the fiber protection sleeve 8 to pass through, and the non-metallic frame 1 is filled with paste-like heat-conducti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com