Method of preparing hydrophobic membrane through physical vapor deposition of fluoroalkyl silane

A technology of physical vapor deposition and fluorosilane, which is applied in the direction of ion implantation plating, coating, metal material coating process, etc., can solve the problems of poor coating adhesion, high cost, poor wear resistance, etc., and achieve the utilization of raw materials The effect of high efficiency, low production cost and short process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention is described in detail below in conjunction with specific embodiments.

[0016] A method for preparing a hydrophobic film by physical vapor deposition of fluorosilane, comprising the following steps:

[0017] One, clean the substrate.

[0018] 2. Plasma glow treatment: Put the base material into PVD vacuum equipment and vacuumize it. When the vacuum degree reaches 10 -2 At Pa, implement plasma glow treatment on the substrate, the ion source current is 0.5-0.8A, the argon flow rate is 100-200SCCM, and the time is 2-5min, so as to achieve the purpose of cleaning and activating the surface of the substrate.

[0019] 3. Intermediate frequency magnetron sputtering transparent silicon oxide film: intermediate frequency power supply 300-1000W, negative bias voltage 100-200V, argon flow rate 30-80SCCM, oxygen flow rate 50-100SCCM, sputtering time 4-7min, sputtering target The material is pure silicon target.

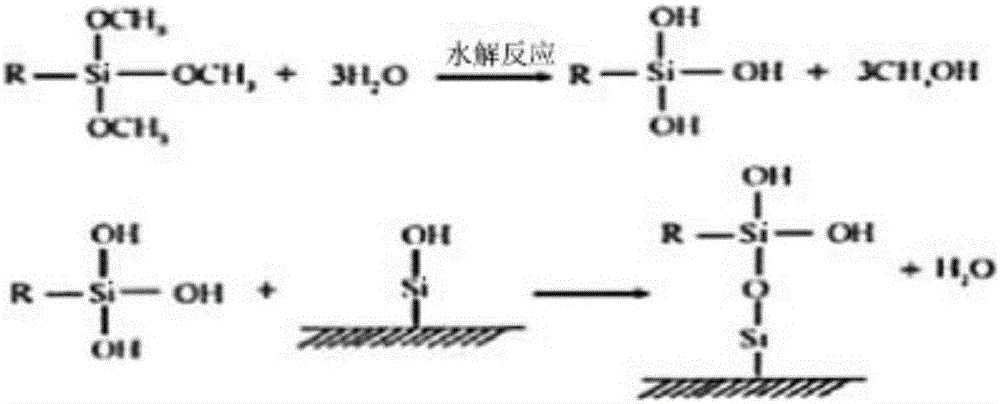

[0020] 4. Vacuum evaporation of fluorosilan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com