Device and method for winding belt layer of radial wire cord tire

A technology of radial tires and winding devices, applied in the field of tire manufacturing, to achieve the effects of cost saving, good binding force, and avoiding stress concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

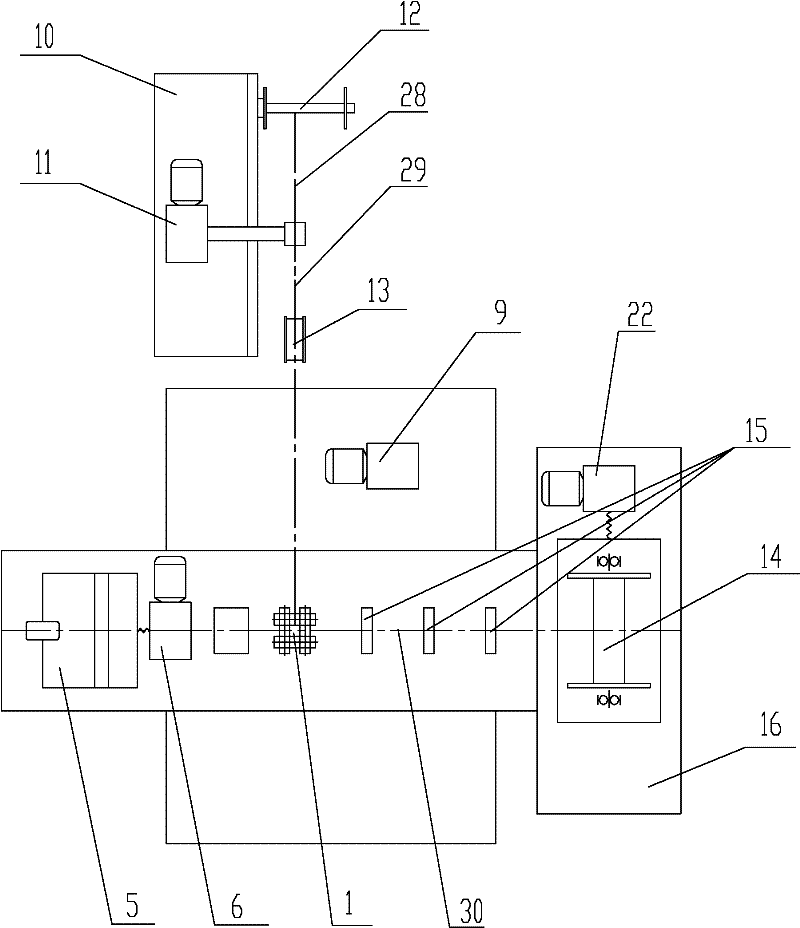

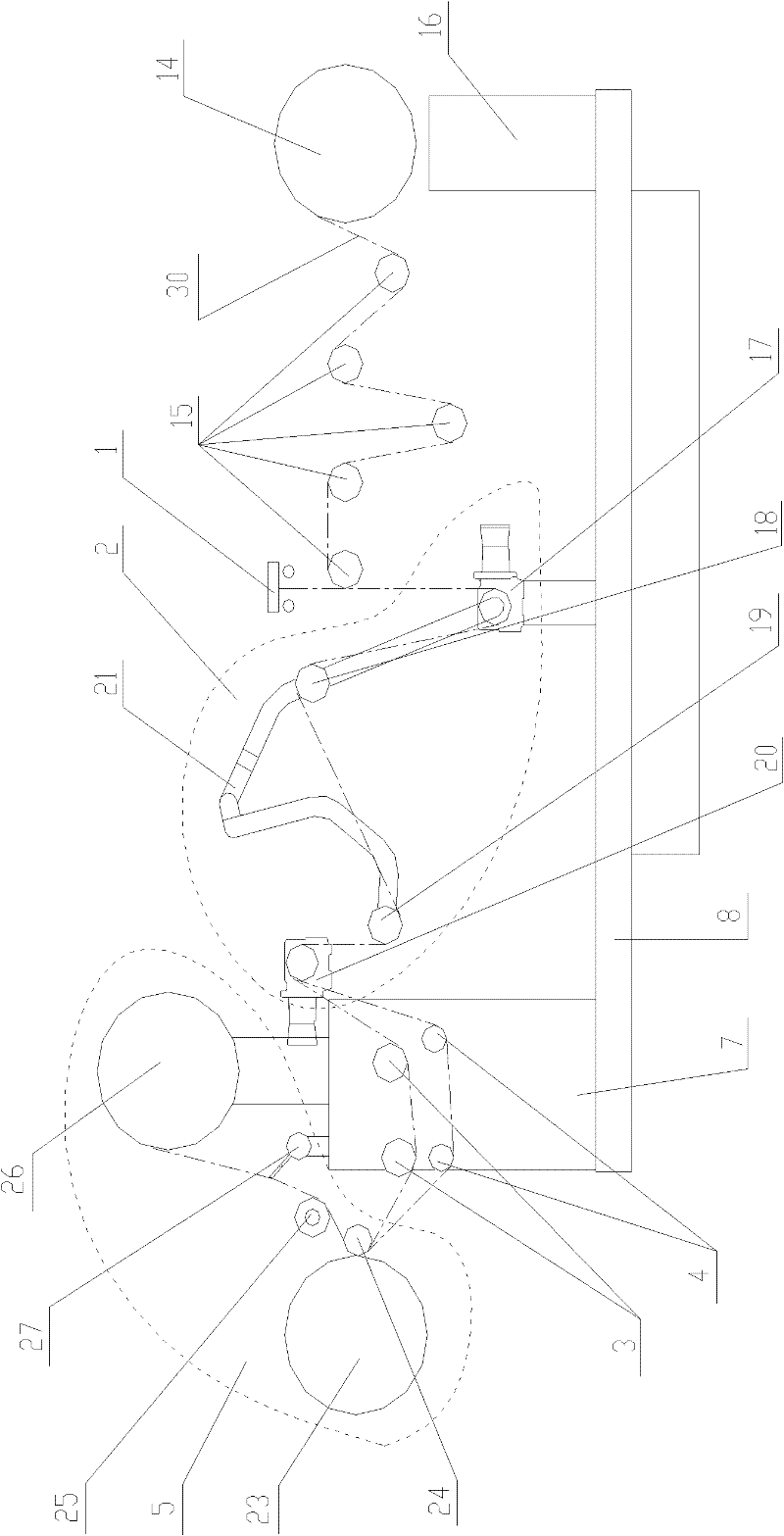

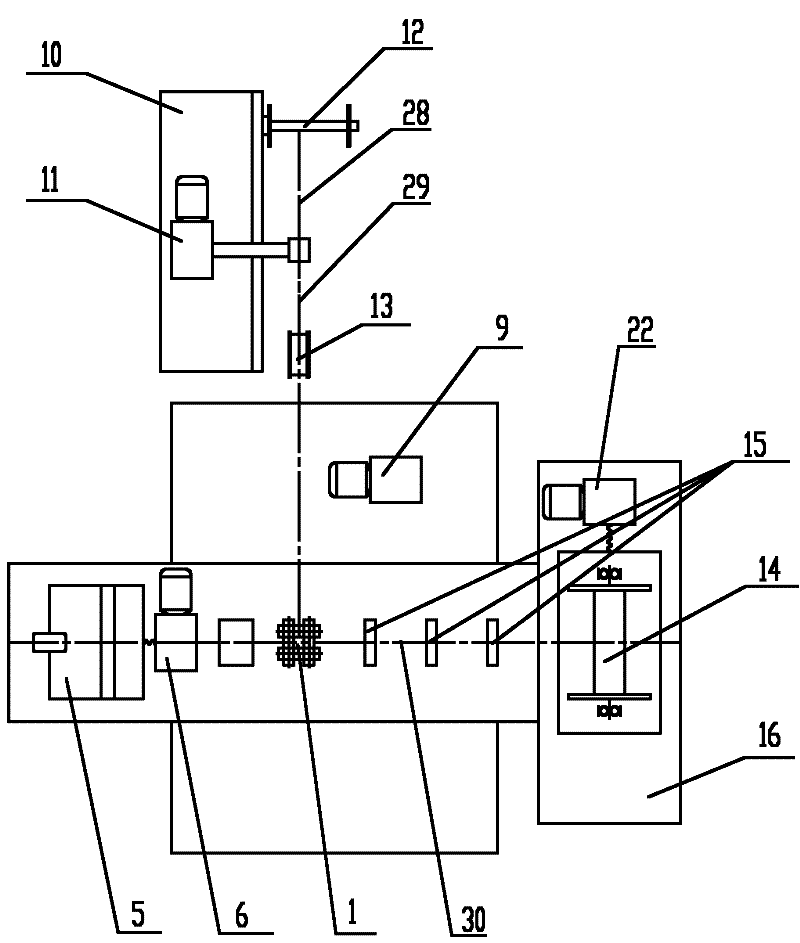

[0031] A kind of steel wire radial tire belt layer winding device of this embodiment, its structure is as follows figure 1 As shown, it includes a steel wire glue coating mechanism, a film unwinding mechanism and a lamination winding mechanism. The steel wire glue coating mechanism is set at the steel wire input end of the lamination winding mechanism, and the film unwinding mechanism is set at the film input end of the lamination winding mechanism; figure 1 As shown in or 2, the bonding winding mechanism includes a steel wire reversing wheel 1, a common guide wheel group 2, a first film guide wheel group 3, a steel wire guide wheel group 4, a winding head 5, a winding head drive assembly 6, and a winding head frame 7. Winding middle frame 8 and middle frame driving assembly 9, according to the conveying direction of steel wire, steel wire reversing wheel 1, common guide wheel group 2, steel wire guide wheel group 4 and winding head 5 are connected in sequence, the first film g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com