Microwave plasma device and method for preparing diamond film and etched carbon film

A microwave plasma and diamond thin film technology, applied in the field of plasma, can solve the problems of unfavorable research and application of plasma technology, expensive equipment and other problems, and achieve the effects of simple structure, high energy conversion efficiency, high performance and price ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

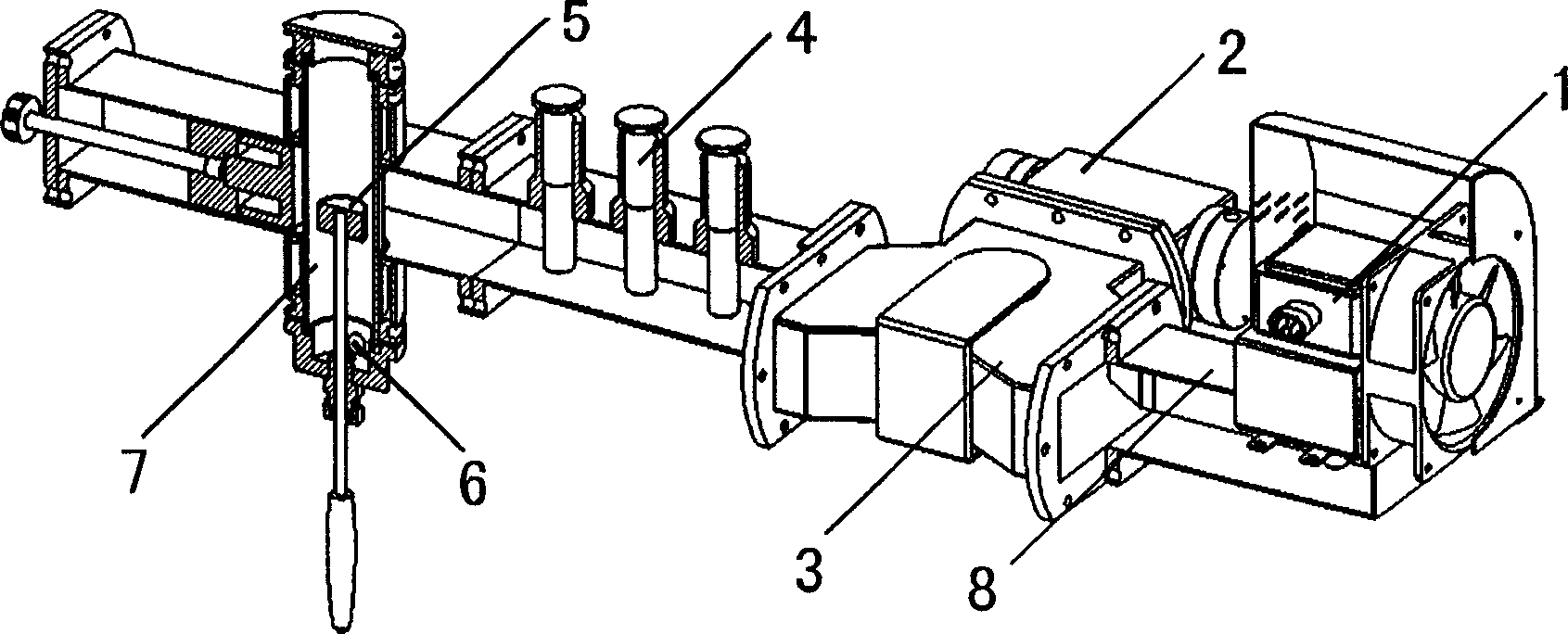

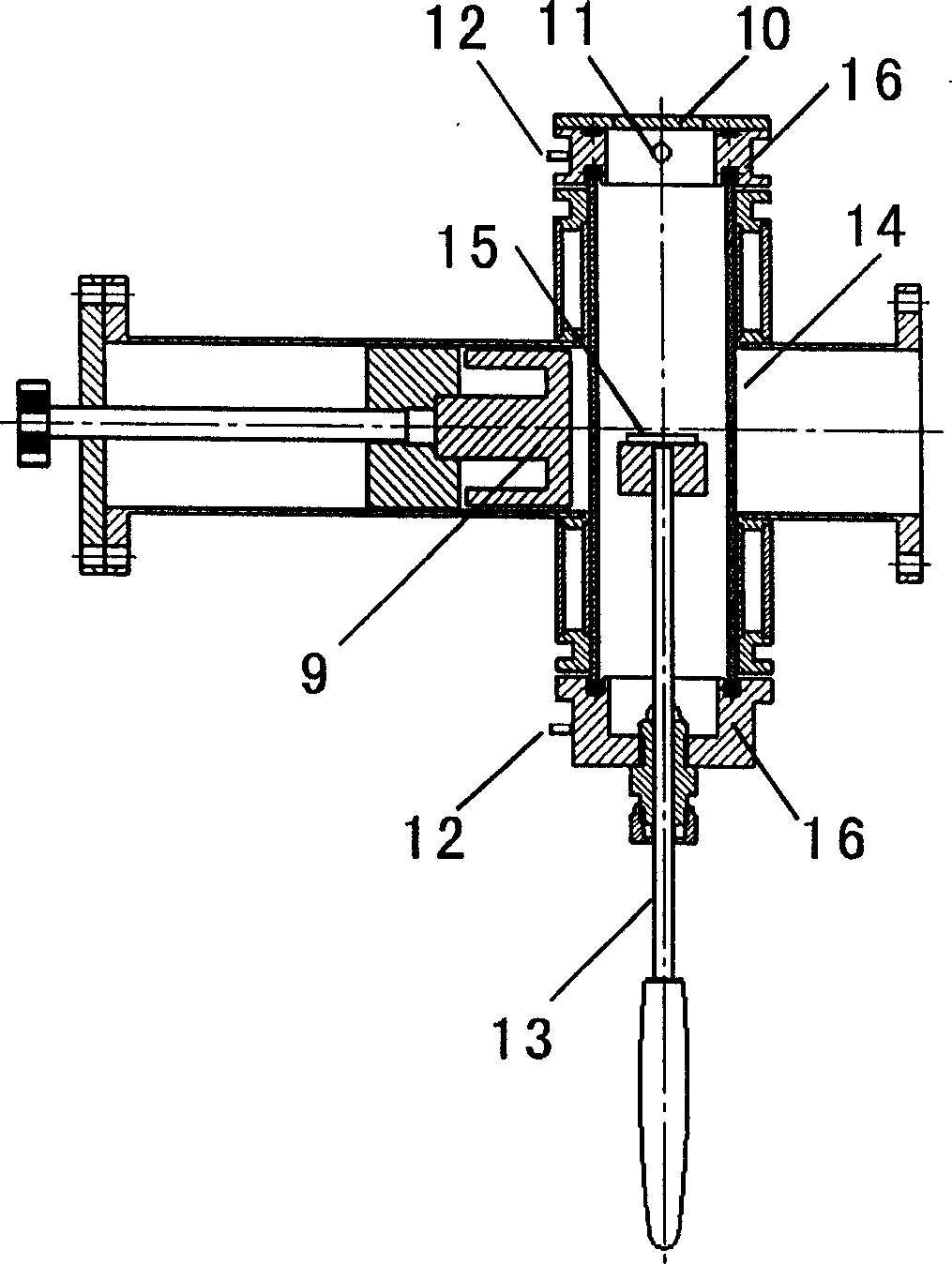

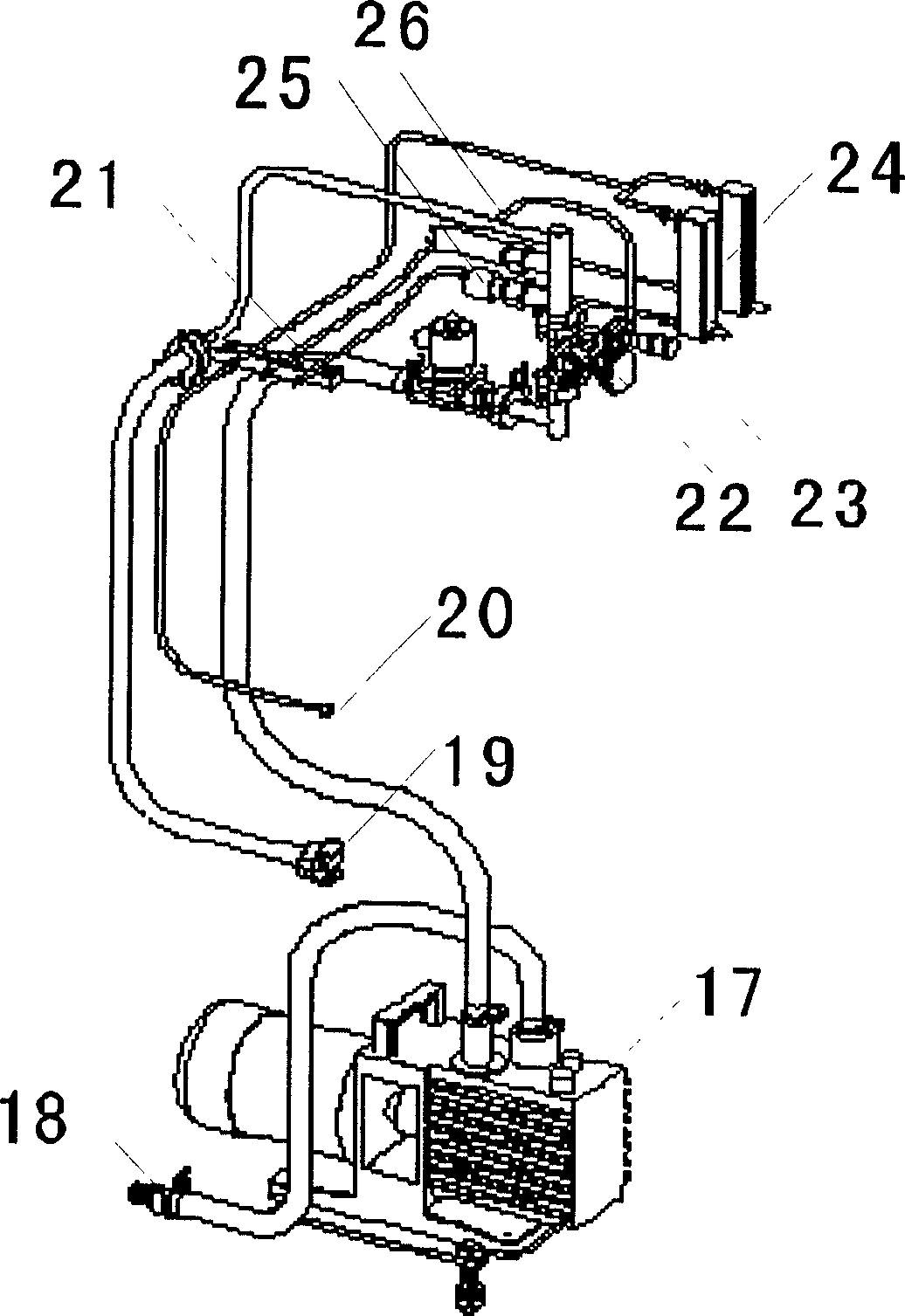

[0027] The markings in the accompanying drawings are as follows:

[0028] 1. Magnetron 2. Water load 3. Circulator

[0029] 4. Three-screw impedance adjuster 5. Substrate table 6. Gas outlet of reaction chamber

[0030] 7. Quartz tube reaction chamber 8. Waveguide 9. Short circuit piston

[0031] 10. Upper observation window 11. Working gas inlet 12. Cooling water connection

[0032] 13. Thermocouple 14. Microwave cavity 15. Substrate

[0033] 16. Water cooling bracket 17. Vacuum pump 18. Exhaust port

[0034] 19. Reaction chamber exhaust pipe 20. Reaction chamber intake pipe 21. Working gas inlet

[0035] 22. Diaphragm valve 23. Trim valve 24. Flow meter

[0036] 25. Pointer vacuum gauge 26. Digital vacuum gauge 27. Circulating water pump

[0037] 28. Cooling water outlet 29. Cooling water return inlet 30. Water tank 31. Compressor

[0038] The present invention will be further described below in combination with embodiments and accompanying drawings.

[0039] A devic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com