Process and system for treating hydrochloric acid-containing wastewater

A technology for acid wastewater and treatment systems, applied in water/sewage treatment, heating water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problems of high wastewater treatment costs, achieve no discharge of three wastes, and have a good operating environment , the effect of avoiding emission pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

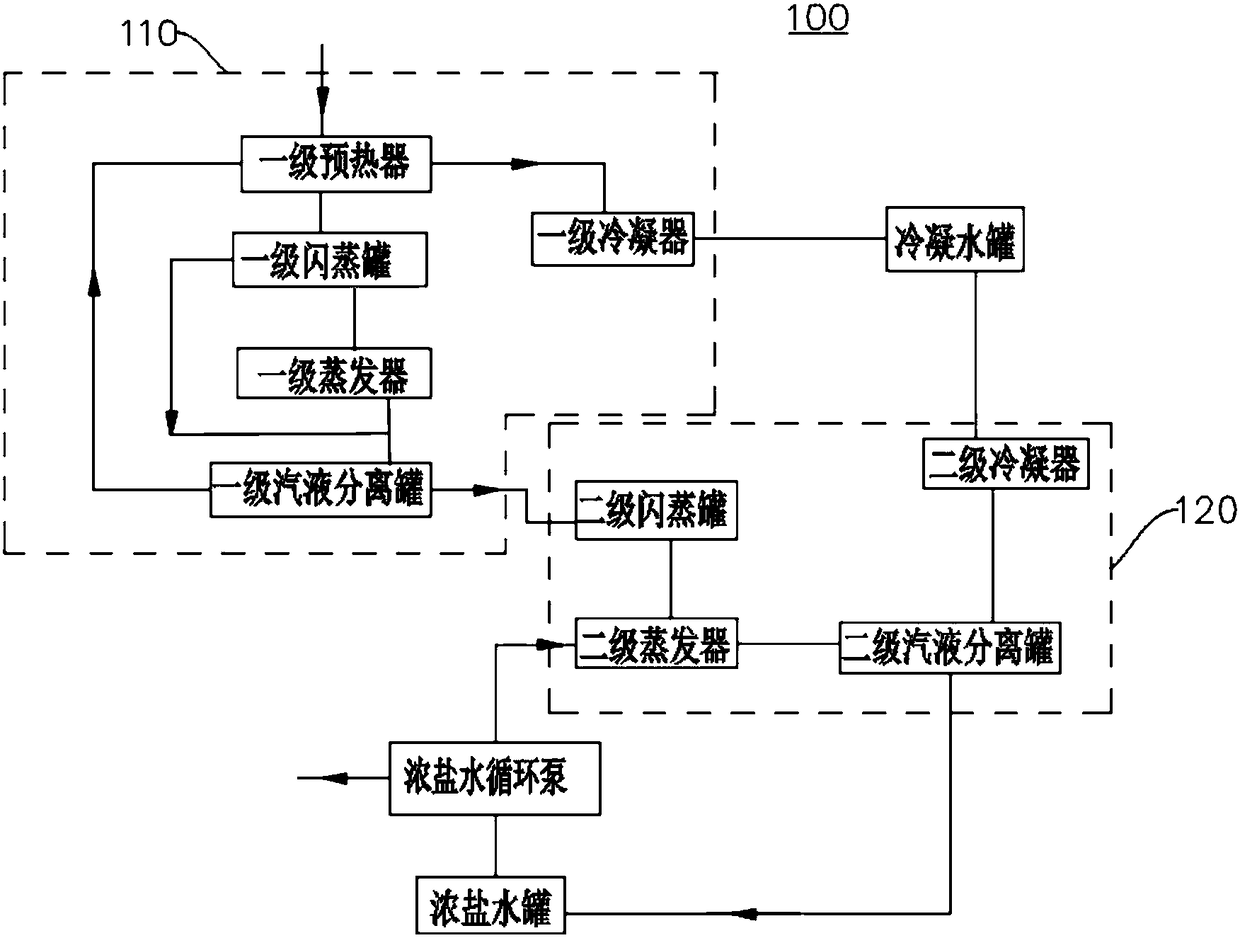

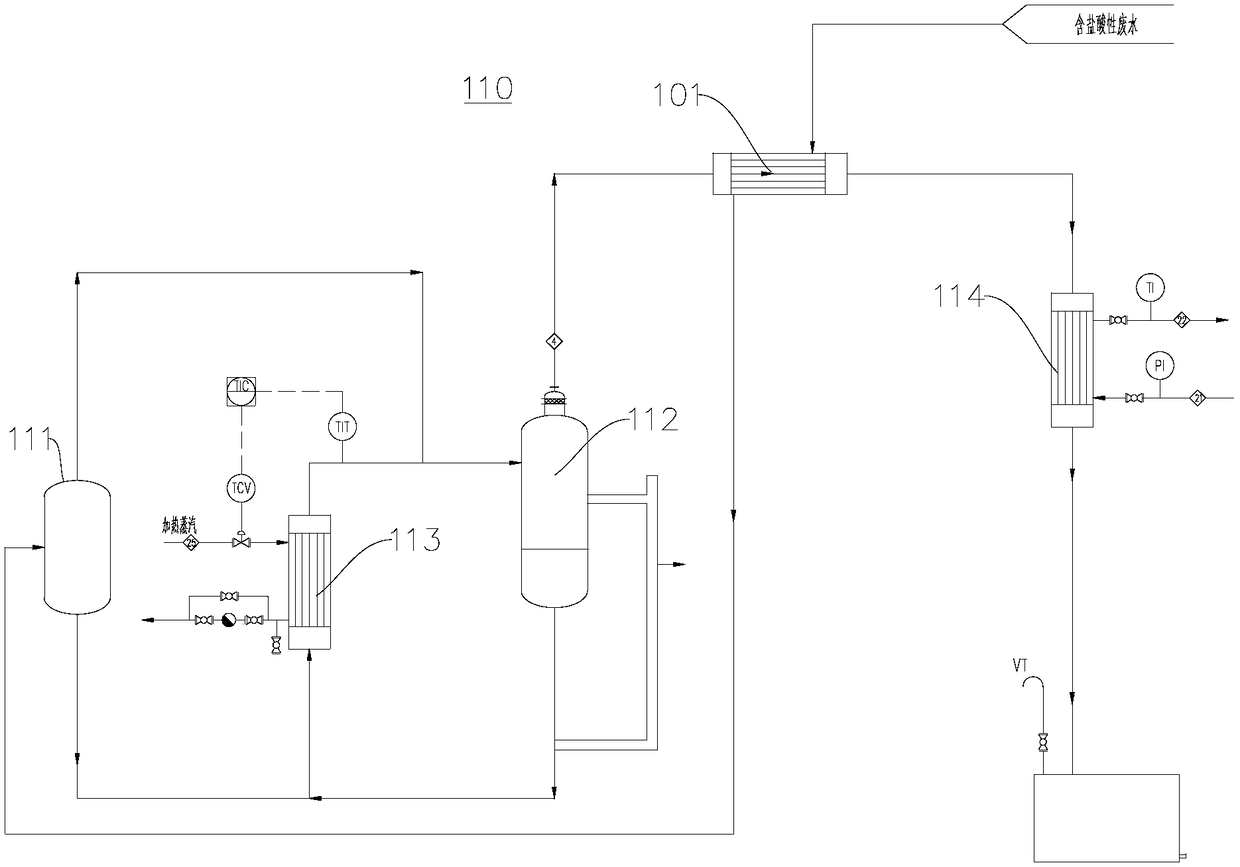

[0049] figure 1 A schematic flow chart of the system 100 for treating acidic acidic wastewater containing salt provided by the embodiment of the present invention is shown. see figure 1 , this embodiment provides a saline-containing acidic wastewater treatment system 100, which is mainly used for the treatment and recovery of saline-containing acidic wastewater.

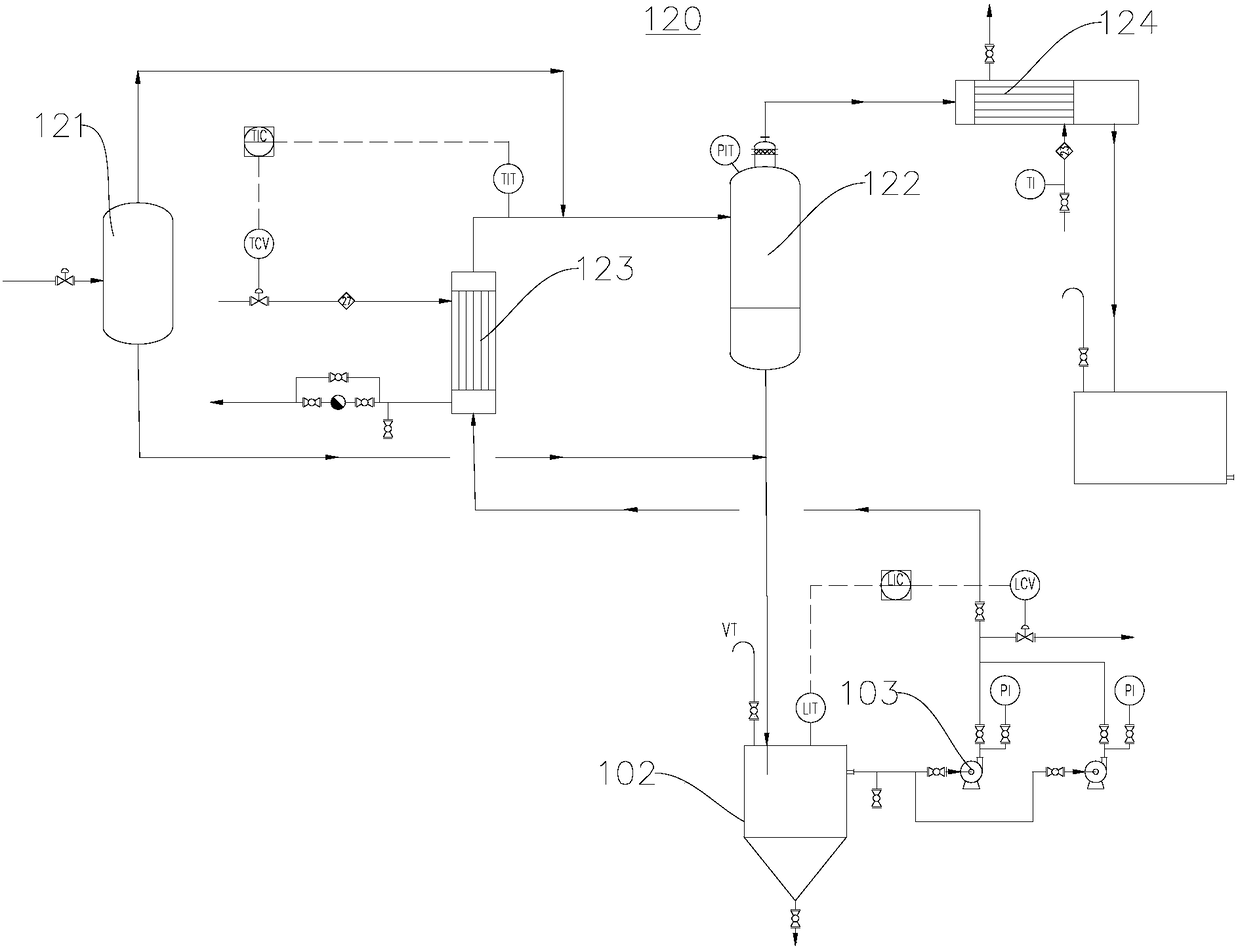

[0050] The hydrochloric acid wastewater treatment system 100 includes a primary evaporation concentration section 110 and a secondary evaporation concentration section 120 . The secondary evaporation concentration section 120 is connected with the primary evaporation concentration section 110 .

[0051] The primary evaporation concentration section 110 includes a primary flash tank 111 and a primary vapor-liquid separation tank 112 ; the primary vapor-liquid separation tank 112 is connected to the primary flash tank 111 .

[0052] The primary flash tank 111, the primary vapor-liquid separation tank 112, the secondar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com