Reactive flame retardant containing double DOPO groups and nitrogen, and preparation method and application thereof

A reactive flame retardant and reaction technology, which is applied in the field of flame retardant materials, can solve problems such as failure to meet the performance requirements of flame retardants, poor flame retardant performance, and field limitations, and achieve improved condensed phase flame retardant effects and reduced carbon residues. The effect of reducing the rate and reducing the amount of addition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example

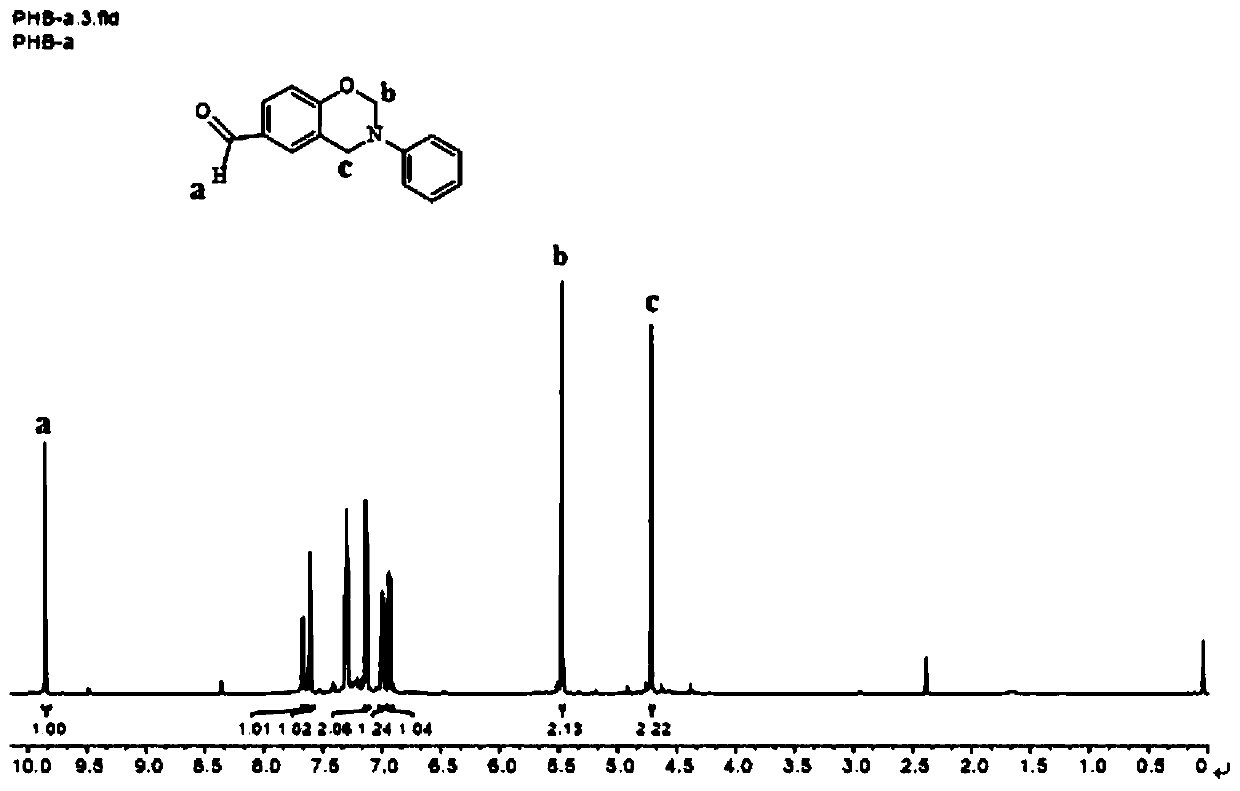

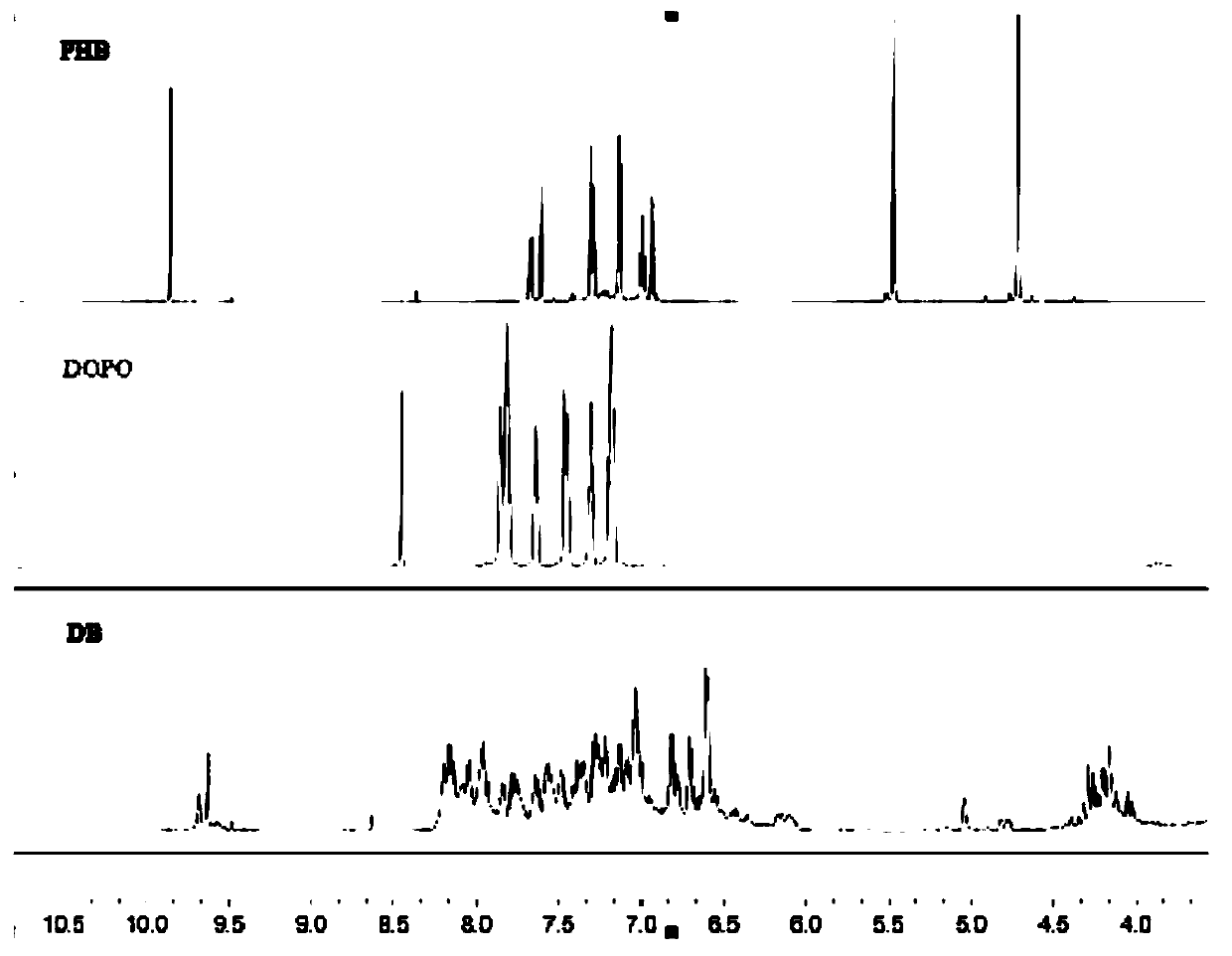

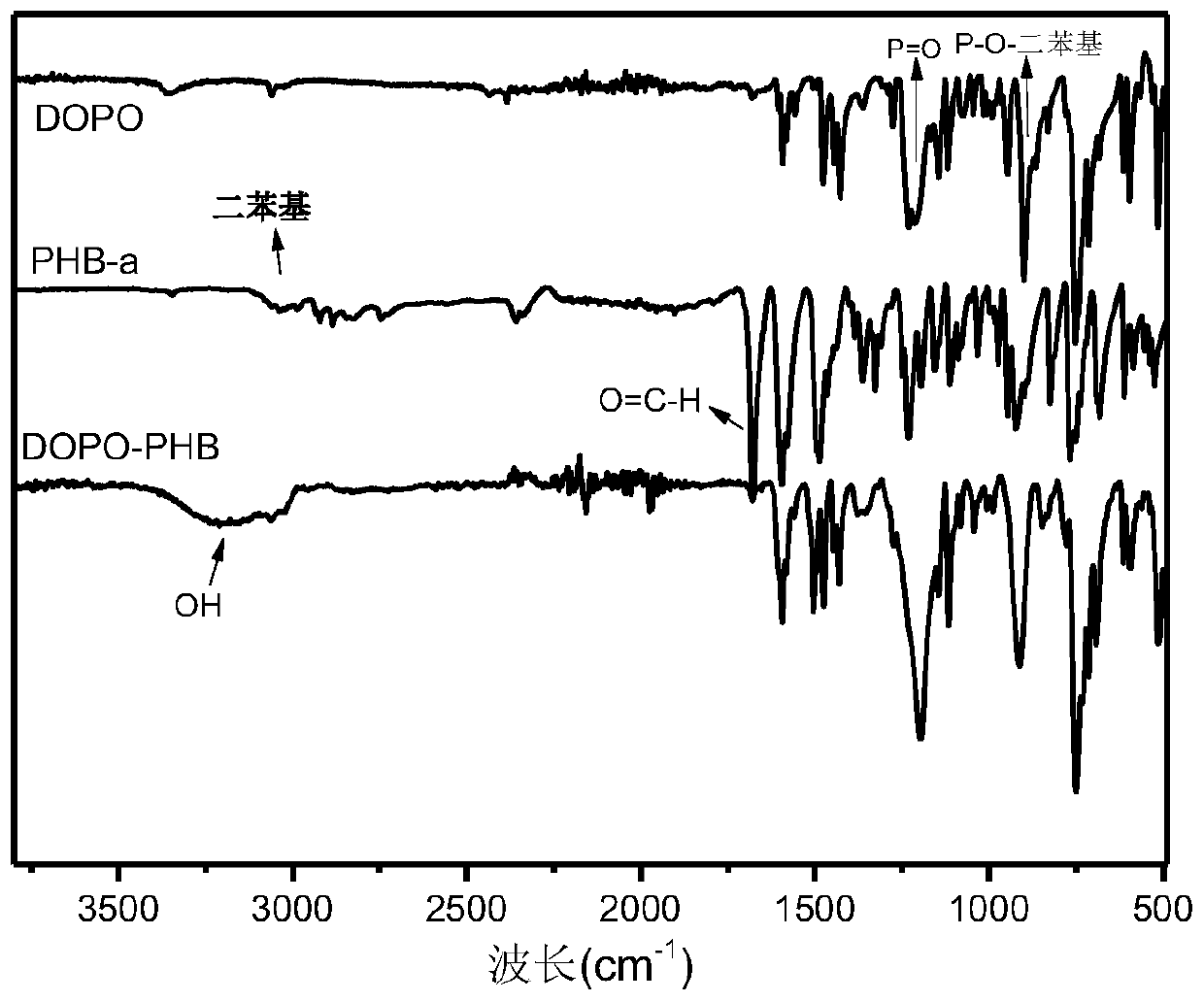

[0037] Dissolve 1.39g (0.015mol) of aniline, 1.22g (0.01mol) of p-hydroxybenzaldehyde and 1.51g (0.05mol) of paraformaldehyde in 50mL of dioxane, and react at 80°C for 10 hours under stirring conditions. After the end, suction filtration under reduced pressure gave a light yellow solid 3-phenyl-6-aldehyde-3,4-dihydro-2H-1,3-benzoxazine PHB with a yield of 94%, and its H NMR spectrum was as follows: figure 1 As shown; 2.39g (0.01mol) of PHB and 6.48g (0.03mol) of DOPO were respectively added into a three-necked flask, and 20ml of anhydrous toluene was added, protected by nitrogen, heated to 130°C, and reacted for 5 hours under magnetic stirring. After the reaction was completed, the solvent was removed by filtration to obtain a light yellow solid, which was then poured into toluene for washing and filtered. Repeat 3 times, thereby remove excessive DOPO, obtain target flame retardant DB, the compound shown in formula (II), product is through proton nuclear magnetic resonance spe...

Embodiment 1

[0045] The preparation of the epoxy resin modified by embodiment 1 reactive flame retardant (DB)

[0046] First, the flame retardant DB synthesized in Preparation Example 1 was ground into powder. Weigh 100g of epoxy resin E-44, raise the temperature to 140°C, add 5g of flame retardant DB, then add 30g of curing agent 4,4'-diaminodiphenylsulfone (DDS), stir well and pour into preheated poly Tetrafluoroethylene mold was kept at 180°C for 4 hours to obtain a flame retardant-modified epoxy resin called PEa1.

[0047] Prepare flame retardant modified epoxy resin samples according to the same method, the difference is that the addition amount of flame retardant DB is different: the addition amount of DB is 10g, and the epoxy resin modified by flame retardant of gained is called PEa2; The addition amount is 15g, and the epoxy resin modified by the flame retardant is called PEa3; and the addition amount of DB is 20g, and the epoxy resin modified by the flame retardant is called PEa4...

Embodiment 2

[0051] Example 2 Preparation of reactive flame retardant (DB) and benzoxazine (PHB) compound system modified epoxy resin:

[0052] First, the flame retardant DB synthesized in Preparation Example 1 was ground into powder. Weigh 100g of epoxy resin E-44, heat up to 140°C, do not add flame retardant DB, then add 30g of curing agent 4,4'-diaminodiphenylsulfone (DDS), 5g of aldehyde benzoxazine ( PHB) is poured into the preheated polytetrafluoroethylene mold after stirring evenly, and is kept at 180 ℃ for 4 hours, and the epoxy resin obtained is called PEb1.

[0053] Prepare flame retardant modified epoxy resin samples according to the same method, the difference is that the addition amount of flame retardant DB is different: the addition amount of DB is 5g, and the epoxy resin modified by flame retardant of gained is called PEb2; The addition amount is 10g, and the epoxy resin modified by the flame retardant is called PEb3; the addition amount of DB is 15g, and the epoxy resin m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| limiting oxygen index | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com