700 MPa-stage-or-over ultra-high-strength weather-resisting steel plate and hot continuous rolling production method thereof

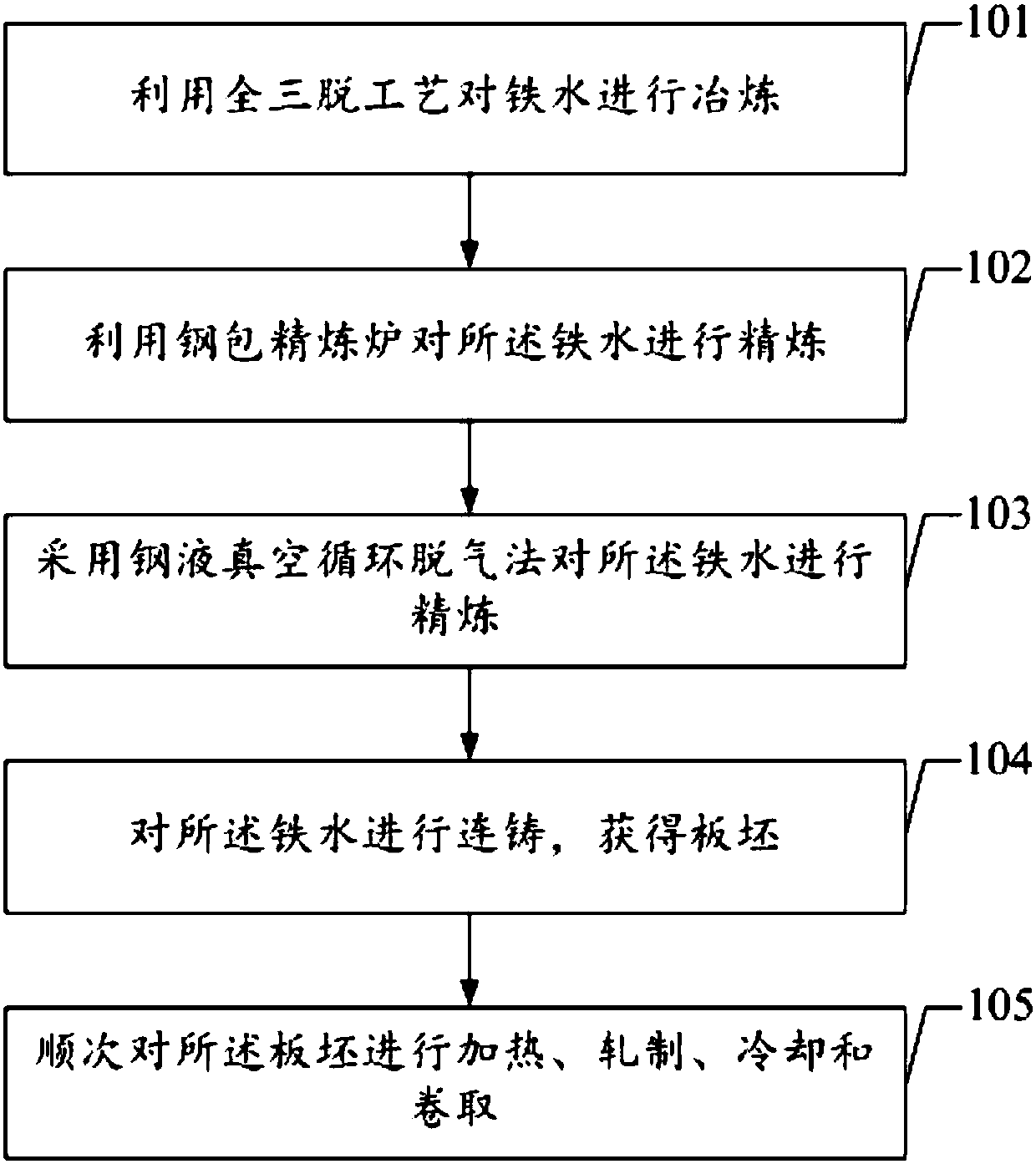

An ultra-high-strength, hot continuous rolling technology, applied in the field of iron and steel smelting, can solve the problems of unsatisfactory weather-resistant steel plate strength, complicated process, and low production efficiency, and achieve good weather resistance, simple process, and high production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] First of all, it is produced by the "full three desulfurization" process, using low-sulfur blast furnace molten iron as raw material, the molten iron is desulfurized by KR, the sulfur content in the molten iron is reduced from 0.039% to 0.0004%, and the desulfurized molten iron is mixed into a 300-ton dephosphorization converter for desulfurization Silicon dephosphorization treatment, adding 17 tons of scrap steel to the dephosphorization furnace, after 7 minutes of oxygen blowing, the semi-steel is produced, the composition of the semi-steel is: C 3.32%, P0.022%, S 0.005%, and then 300 tons of decarburization converter Load copper plates, nickel plates and semi-steel for further decarburization and temperature-raising blowing. The final composition is: C 0.039%, P0.0065%, S0.007%, and the tapping temperature of the converter is 1676°C. During the process, Si-Mn, medium carbon Mn-Fe and Cr-Fe are added for alloying treatment. When the molten steel in the ladle is about 1...

Embodiment 2

[0058]First of all, it is produced by the "full three desulfurization" process, using low-sulfur blast furnace molten iron as raw material. The molten iron is desulfurized by KR, and the sulfur content in the molten iron is reduced from 0.034% to 0.0001%. The desulfurized molten iron is mixed into a 300-ton dephosphorization converter for desulfurization Silicon dephosphorization treatment, adding 17 tons of scrap steel to the dephosphorization furnace, after 8 minutes of oxygen blowing, the semi-steel is produced, the composition of the semi-steel is: C 3.29%, P0.024%, S 0.004%, and then 300 tons of decarburization converter Load copper plates, nickel plates and semi-steel for further decarburization and temperature-raising blowing. The final composition is: C 0.034%, P0.008%, S0.007%, and the tapping temperature of the converter is 1667°C. During the process, Si-Mn, medium carbon Mn-Fe and Cr-Fe are added for alloying treatment. When the molten steel in the ladle is about 120...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com