Technological method of using high-phosphorus molten iron to produce ultralow-phosphorus steel

A process method, the technology of ultra-low phosphorus steel, applied in the field of iron and steel smelting, can solve the problems of deterioration of steel impact toughness, cold brittleness, and increase of steel ductile-brittle transition temperature, so as to reduce phosphorus content, reduce production costs, and optimize steelmaking process The effect of the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

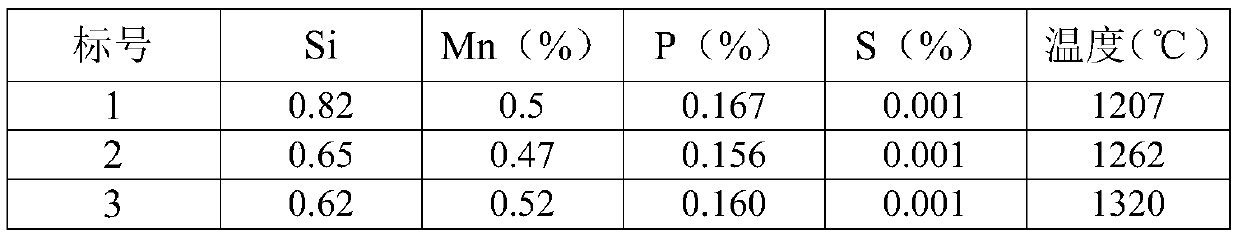

[0039] 1. Pretreatment of KR molten iron: The labels of the 7 furnaces of molten steel produced by continuous smelting are 1 to 7 in sequence. %.

[0040] Table 1 Situation of molten iron after KR desulfurization treatment (%)

[0041]

[0042]

[0043] 2. Converter smelting: control the final slag alkalinity, the blowing temperature at the end point; block the slag and tap the steel, blow the argon gas at the bottom of the ladle before tapping and stir for 1-2 minutes, and blow the argon gas at the bottom of the ladle to stir during the tapping process, and do not add molten steel for deoxidation agent and slag deoxidizer; the end temperature of converter smelting, the basicity of final slag and the composition of tapping molten steel are listed in Table 2. It can be seen from Table 2 that the P content of the steel is 0.0065-0.0123%, and the average dephosphorization rate is 94.1%. Furthermore, by controlling the end point temperature at 1600-1620°C, the P content ca...

Embodiment 2

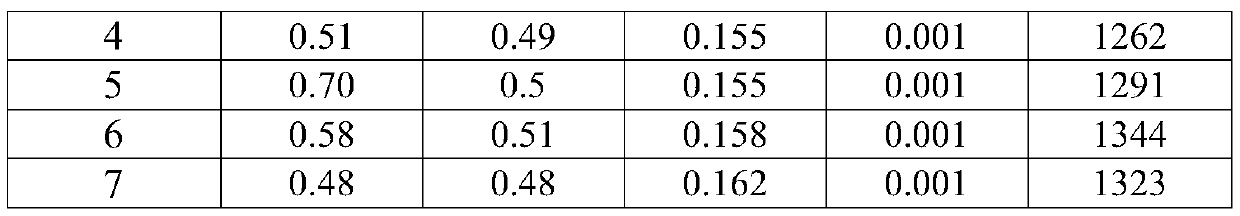

[0054] 1. Pretreatment of KR molten iron: the grades of the 4 furnaces of molten steel produced by continuous smelting are 8-11 in sequence. %.

[0055] Table 5 Situation of molten iron after KR desulfurization treatment

[0056] label

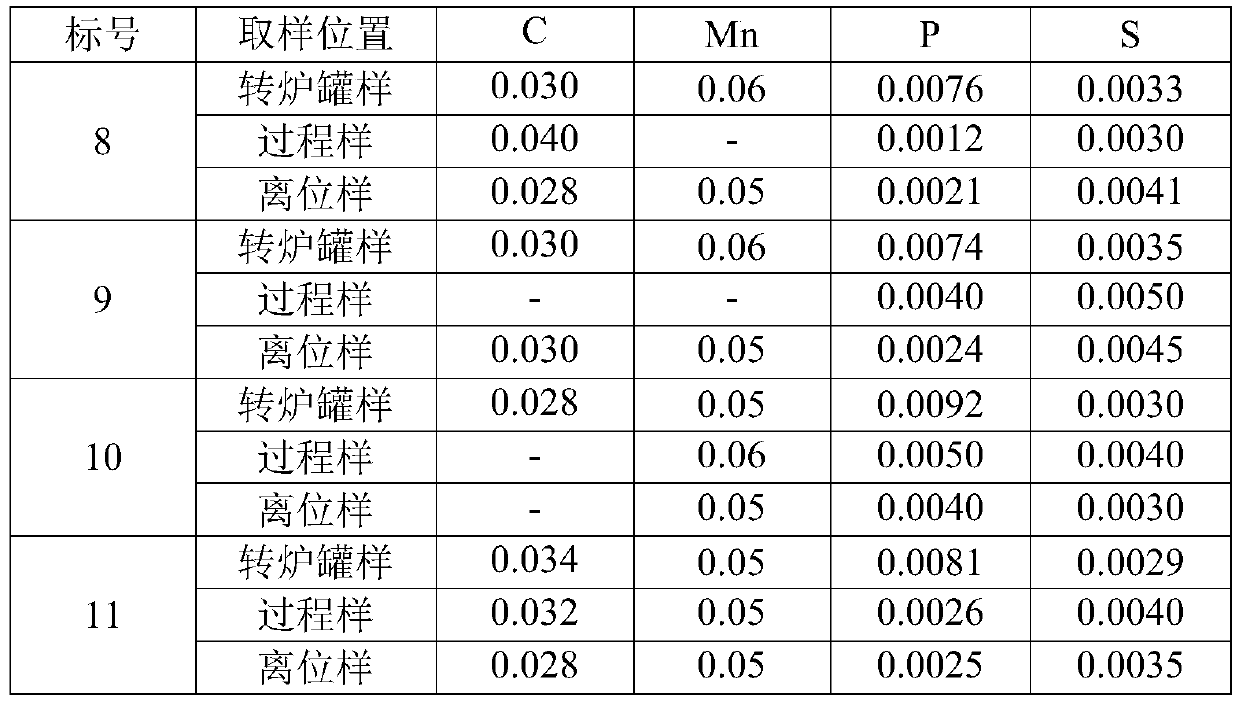

[0057] 2. Converter smelting: control the final slag alkalinity, the blowing temperature at the end point; block the slag and tap the steel, blow the argon gas at the bottom of the ladle before tapping and stir for 1-2 minutes, and blow the argon gas at the bottom of the ladle to stir during the tapping process, and do not add molten steel for deoxidation agent and slag deoxidizer; converter smelting end temperature, final slag basicity and tapping molten steel composition are listed in Table 6. It can be seen from Table 2 that the content of P in the steel is 0.010-0.012%.

[0058] Table 6 Composition of tapping at the end of converter (%) and end temperature of blowing (℃)

[0059] label

[0060] 3. LF refining: during...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com