Gas protection welding wire for nuclear power steel containment vessel

A gas shielded welding wire and containment technology, applied in welding media, welding equipment, welding/cutting media/materials, etc., can solve the problems of the impact of the third-generation nuclear power plant project progress, different welding quality, high cost, etc., and achieve the welding process. Good performance and physical and chemical properties, small splash, beautiful molding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The gas-shielded welding wire used for nuclear power steel containment is characterized in that the chemical composition is:

[0038] C: 0.081%

[0039] Mn: 1.54%

[0040] Si: 0.44%

[0041] Ni: 1.02%;

[0042] S: 0.003%;

[0043] P: 0.005%;

[0044] Cr: 0.045%;

[0045] Mo: 0.14%;

[0046] Cu: 0.11%;

[0047] The remainder is iron and unavoidable impurities.

[0048] The welding wire obtained in this embodiment is made of 80%Ar+20%CO 2 Shielding gas, using DC reverse connection for welding test, stable arc, small spatter, beautiful weld shape.

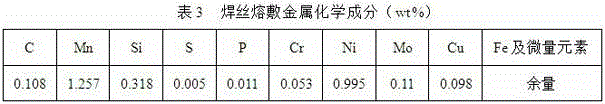

[0049] The chemical composition of the deposited metal of the welding wire is shown in Table 1, and the mechanical properties of the deposited metal are shown in Table 2.

[0050]

[0051]

Embodiment 2

[0053] The gas-shielded welding wire used for nuclear power steel containment is characterized in that the chemical composition is:

[0054] C: 0.085%

[0055] Mn: 1.49%

[0056] Si: 0.40%

[0057] Ni: 0.98%;

[0058] S: 0.004%;

[0059] P: 0.005%;

[0060] Cr: 0.05%;

[0061] Mo: 0.14%;

[0062] Cu: 0.12%;

[0063] The remainder is iron and unavoidable impurities.

[0064] The welding wire obtained in this embodiment is made of 80%Ar+20%CO 2 Shielding gas, using DC reverse connection for welding test, stable arc, small spatter, beautiful weld shape.

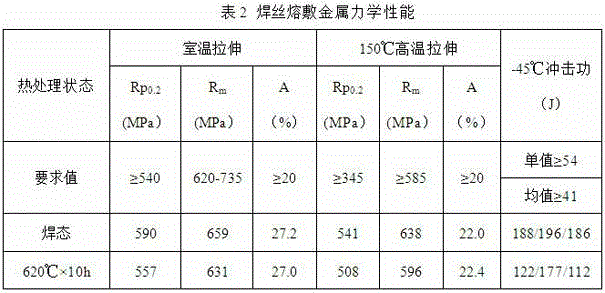

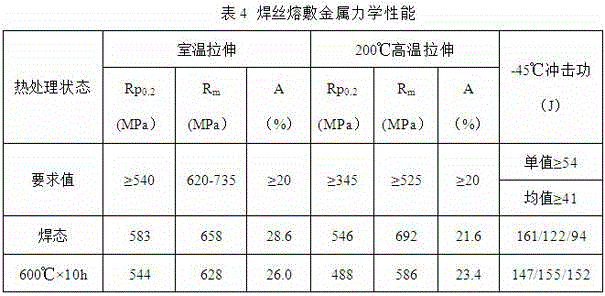

[0065] The chemical composition of the deposited metal of the welding wire is shown in Table 3, and the mechanical properties of the deposited metal are shown in Table 4.

[0066]

[0067]

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com