Preparation method of corrosion-resisting high-conductivity wood electromagnetic shielding material

An electromagnetic shielding material and high conductivity technology, which is applied in the direction of metal material coating process, coating, liquid chemical plating, etc., can solve the problems of poor corrosion resistance and achieve strong corrosion resistance, fine coating, and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0027] Specific embodiment one: the preparation method of the corrosion-resistant highly conductive wooden electromagnetic shielding material of the present embodiment, carry out according to the following steps:

[0028] 1. The concentration of nickel sulfate is 20-40g / L, the concentration of sodium hypophosphite is 20-40g / L, the concentration of sodium citrate is 10-30g / L, the concentration of lactic acid is 2-10ml / L, acetic acid The concentration of sodium is 10-30g / L, and the concentration of thiourea is 1-5mg / L. Add nickel sulfate, sodium hypophosphite, sodium citrate, lactic acid, sodium acetate and thiourea into the water, mix well, and adjust the pH value 8 to 10 to obtain a solution;

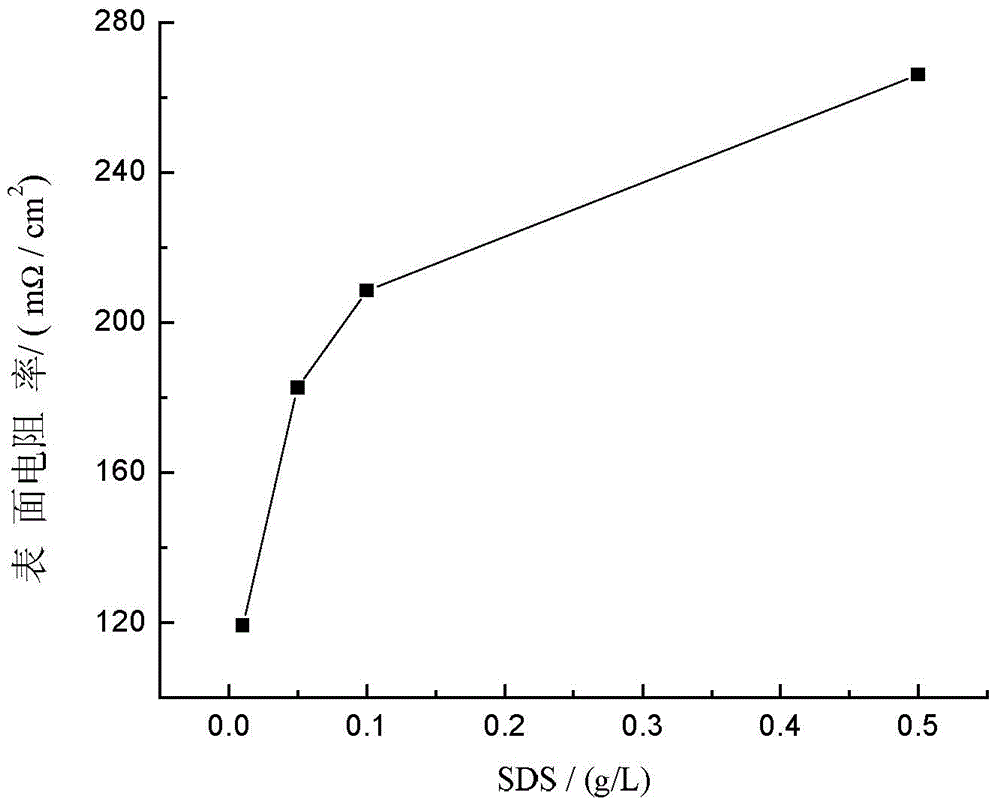

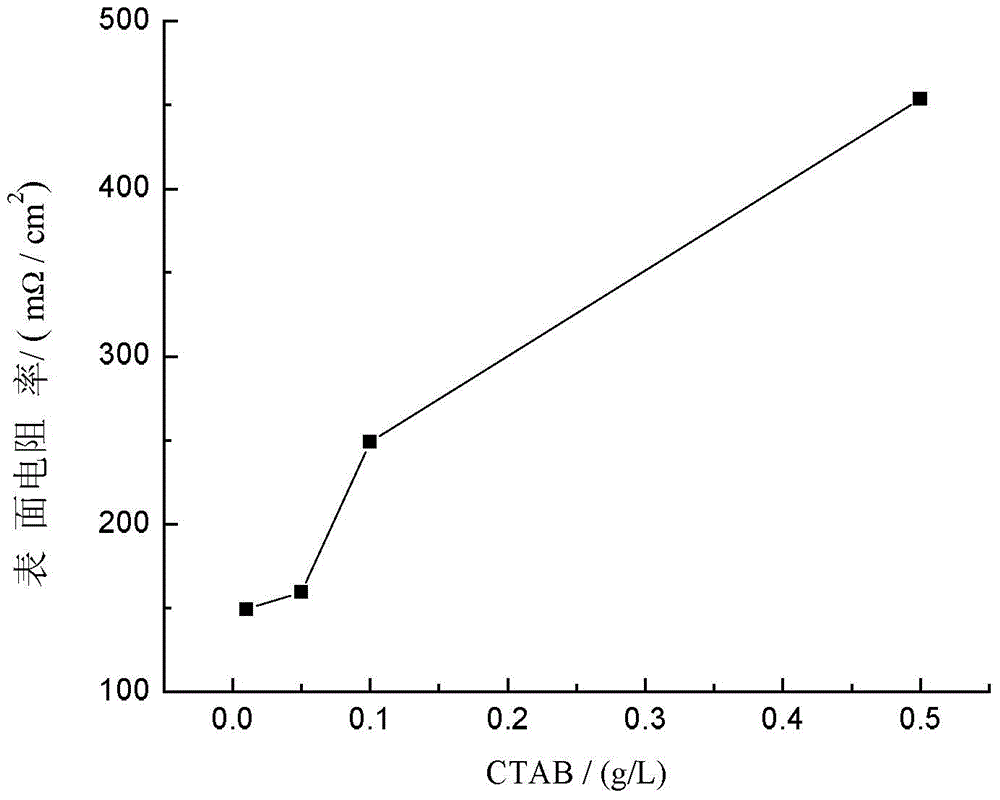

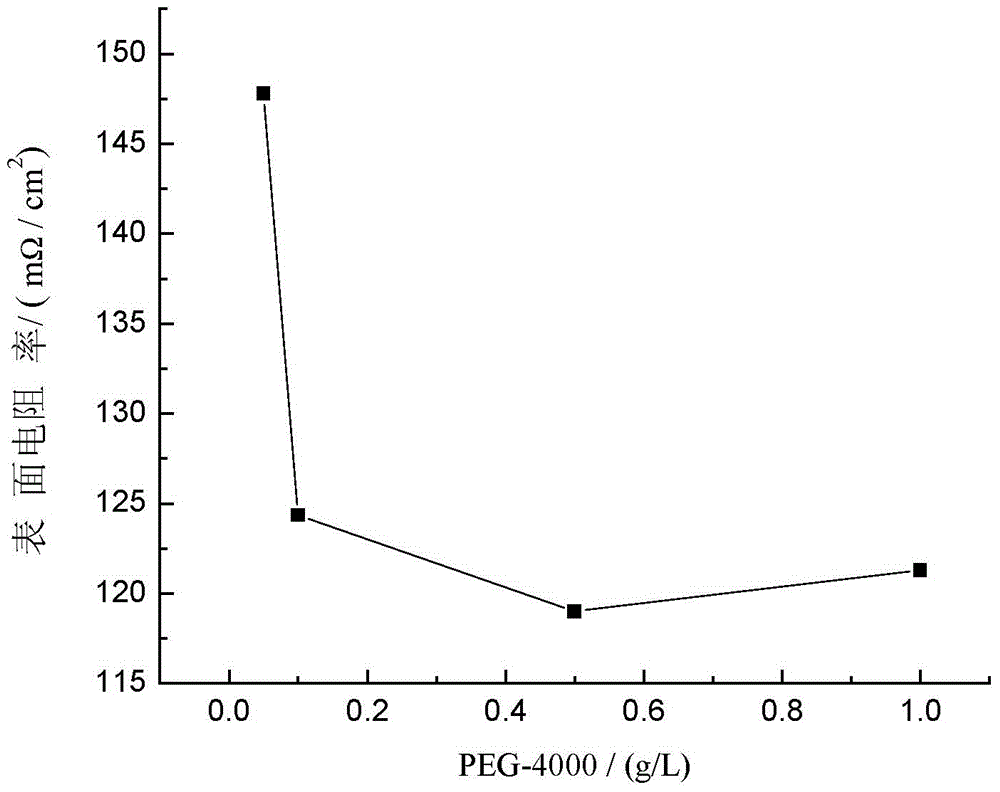

[0029] 2. Add the surfactant and nano-alumina to the solution prepared in step 1, and ultrasonically disperse for 30-90 minutes to obtain a plating solution; the concentration of nano-alumina in the plating solution is 0.2-5g / L; the surfactant is the surface active agent. The active ag...

specific Embodiment approach 2

[0031] Specific embodiment two: the difference between this embodiment and specific embodiment one is that the concentration of nickel sulfate in step one is 30g / L, the concentration of sodium hypophosphite is 30g / L, the concentration of sodium citrate is 20g / L, lactic acid The concentration of sodium acetate is 5ml / L, the concentration of sodium acetate is 20g / L, and the concentration of thiourea is 3mg / L. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0032] Specific embodiment three: the difference between this embodiment and specific embodiment one is that the concentration of nickel sulfate in step one is 35g / L, the concentration of sodium hypophosphite is 25g / L, the concentration of sodium citrate is 25g / L, lactic acid The concentration of sodium acetate is 7ml / L, the concentration of sodium acetate is 18g / L, and the concentration of thiourea is 4mg / L. Others are the same as in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com