Special compound premixed feed lick brick for dairy cows in perinatal period

A pre-mixed feed, perinatal technology, applied in the direction of animal feed, animal feed, animal feed molding or processing, etc., can solve the problem of not being able to adapt well to perinatal dairy cows, etc., to improve feed conversion rate, easy to absorb , the effect of enhancing the activity of enzymes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

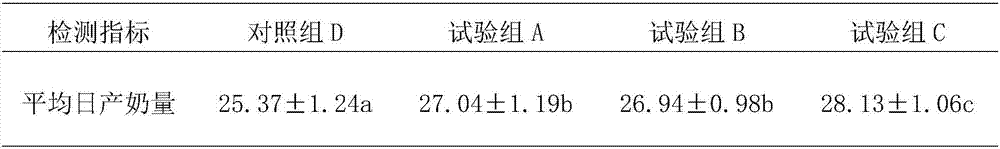

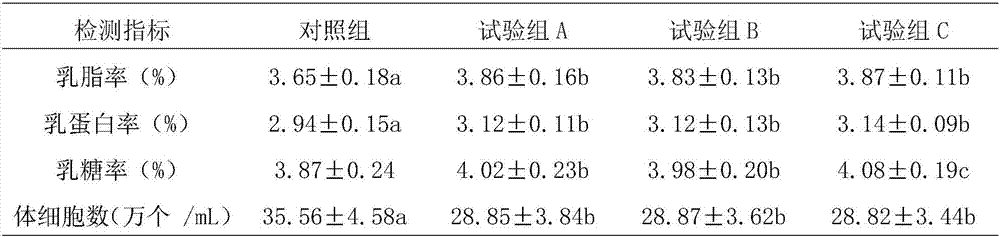

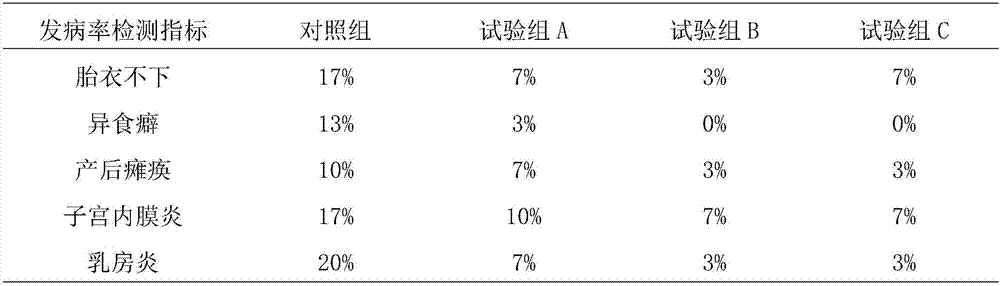

Examples

Embodiment 1

[0025] Produce Licking Brick A according to the following method:

[0026] The raw materials are proportioned according to the following formula: table salt 44.00%, cement 6.00%, bentonite 8.00%, calcium propionate 1.70%, bacitracin zinc 1.30%, sodium content 45.96% of baking soda 3.00%, calcium content of 30% 1.00% calcium formate, 8.00% calcium carbonate with 38.42% calcium by mass, 4.45% calcium hydrogen phosphate with 24.58% phosphorus by mass, fragrance 0.05%, iron glycinate 5.30% with 17% iron by mass, copper mass 1.00% copper glycinate than 15%, 4.20% zinc glycinate with 17% zinc by weight, 1.60% magnesium oxide with 15% magnesium by weight, manganese glycinate 4.20% with 15% manganese by weight, and selenium weight ratio 0.2 % Yeast selenium 2.40%, cobalt containing 1.24% by mass of cobalt chloride 0.50%, iodine containing 1.24% by mass of calcium iodate 0.30%, rumen 1.00%, composite multidimensional 2.00%; the composite multidimensional has the following mass The percen...

Embodiment 2

[0032] Produce Licking Brick B according to the following method:

[0033] The raw materials are proportioned according to the following formula: salt 50.00%, cement 6.40%, bentonite 11.50%, calcium propionate 1.20%, bacitracin zinc 1.10%, sodium content 45.96% of baking soda 2.60%, calcium content of 30% 0.70% of calcium formate, 7.00% of calcium carbonate with 38.42% of calcium by mass, 3.57% of dicalcium phosphate with 24.58% of phosphorus by mass, 0.03% of fragrance, and 3.30% of iron glycinate with 17% of iron by mass. Copper 0.60% copper glycinate with 15%, 2.80% zinc glycinate with 17% zinc by mass, 1.00% magnesium oxide with 15% magnesium by mass, manganese glycinate 3.50% with 15% manganese by mass, and selenium 0.2% by mass % Yeast selenium 1.60%, cobalt content 1.24% cobalt chloride 0.30%, iodine content 1.24% calcium iodate 0.20%, rumen 0.80%, composite multi-dimensional 1.80%; the composite multi-dimensional consists of the following mass The percentage of each comp...

Embodiment 3

[0039] According to the following method to produce licking brick C:

[0040] Proportion of raw materials according to the following formula: salt 42.00%, cement 4.00%, bentonite 6.00%, calcium propionate 1.55%, bacitracin zinc 1.50%, sodium content 45.96% of baking soda 3.10%, calcium content of 30% Calcium formate 1.30%, calcium carbonate with 38.42% calcium by mass 9.00%, phosphorous with 24.58% calcium hydrogen phosphate 4.80%, flavoring agent 0.05%, iron with 17% iron glycinate 6.10%, copper 1.20% copper glycinate than 15%, 4.60% zinc glycinate with 17% zinc by weight, 1.80% magnesium oxide with 15% magnesium by weight, manganese glycinate 5.50% with 15% manganese by weight, and selenium weight ratio 0.2 % Yeast selenium 3.00%, cobalt containing 1.24% by mass of cobalt chloride 0.70%, iodine containing 1.24% by mass of calcium iodate 0.40%, rumen 1.30%, composite multidimensional 2.10%; the composite multidimensional consists of the following masses The percentage of each c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com