Multi-rigidity sole die and sole

A multi-hardness and base technology, applied in the direction of shoe soles, footwear, applications, etc., can solve the problems of lack of cushioning, reduce comfort, increase unsafe factors, etc., and achieve the goal of improving friction, ensuring comfort, and improving wrapping Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

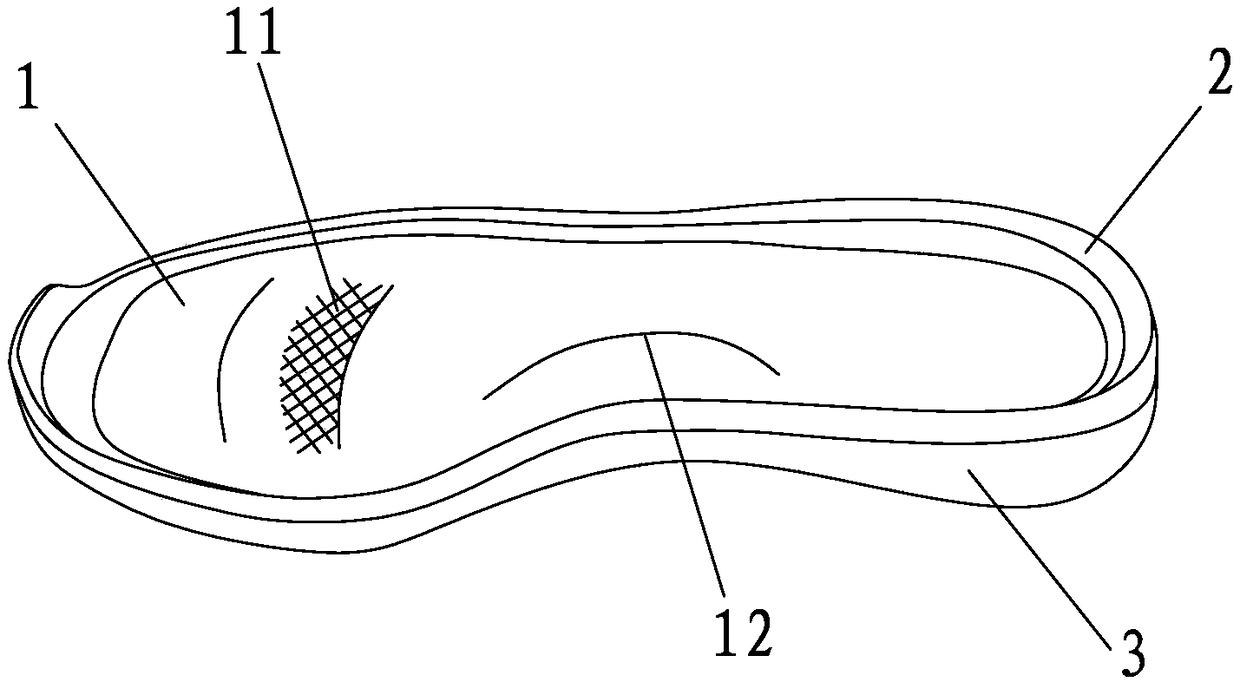

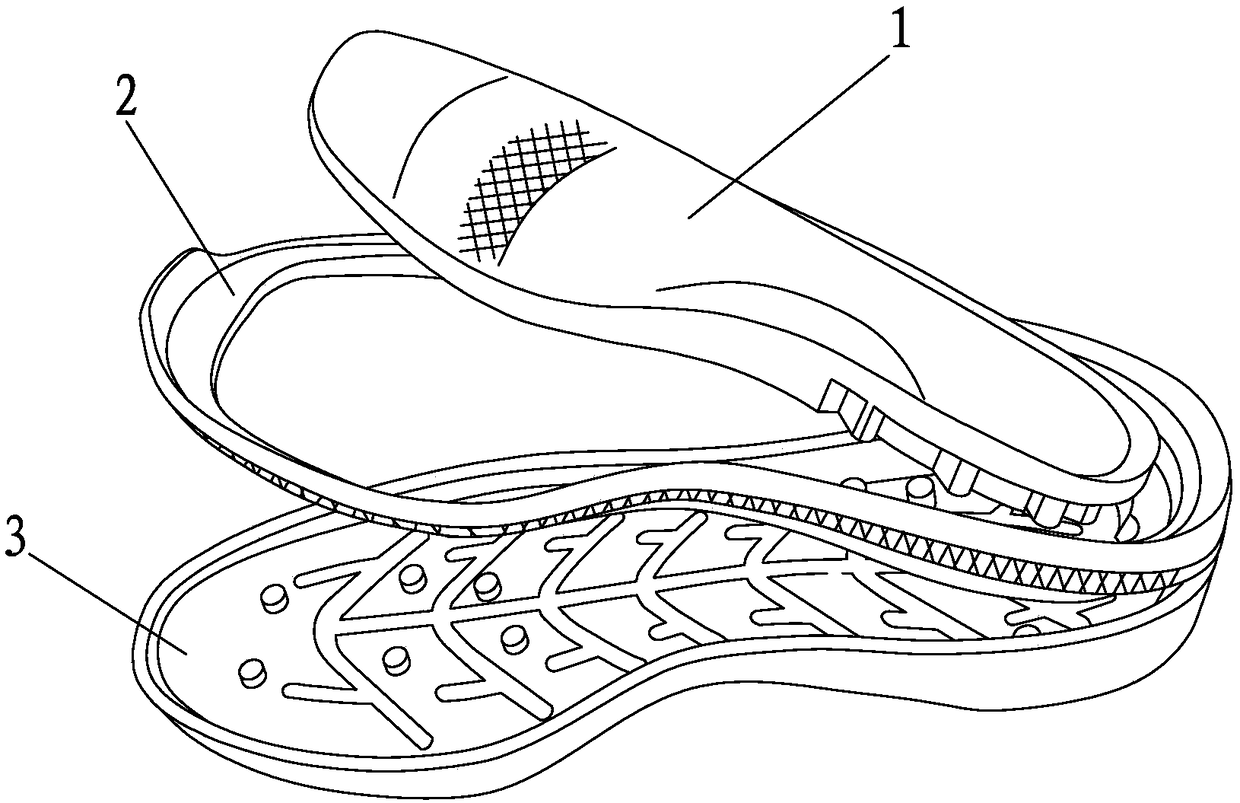

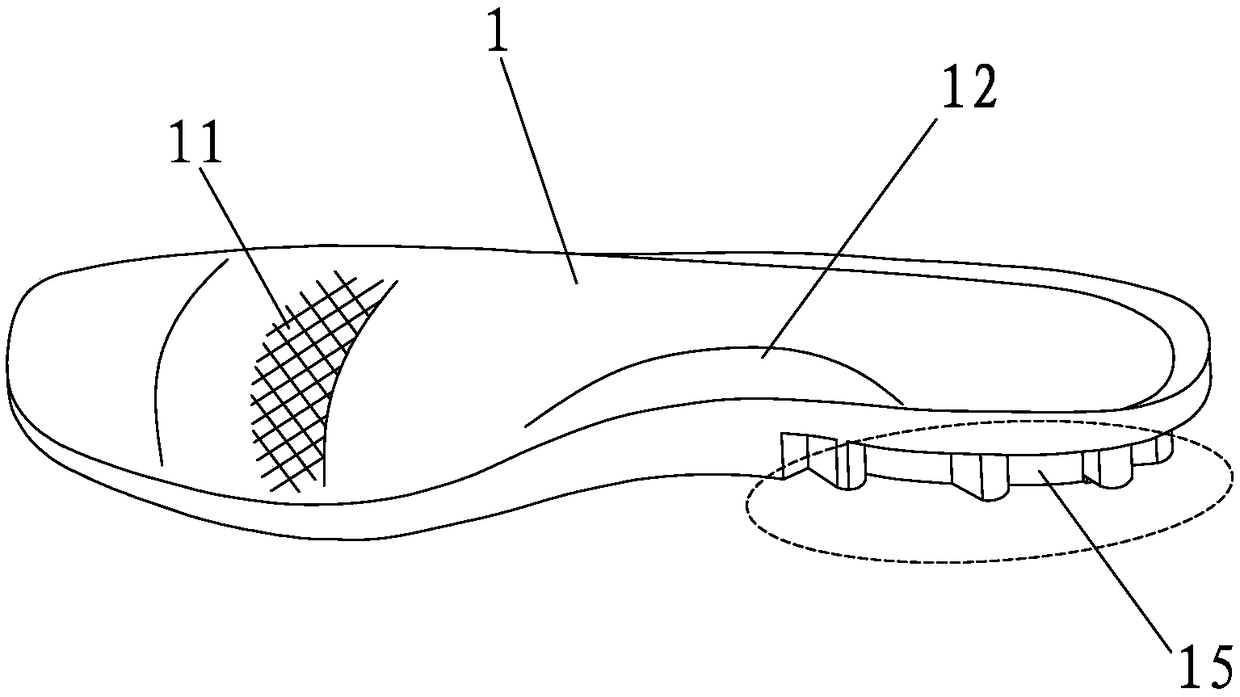

[0054] A kind of multi-hardness shoe sole embryo of the present invention, as Figure 1-Figure 8 As shown, it includes an inner core embryo 1 and a sole body embryo, and the shoe sole body embryo includes an upper ring embryo 2 and a lower bottom embryo 3 . The inner core embryo 1, the upper ring embryo 2 and the lower bottom embryo 3 are injection molded by EVA materials with different hardness respectively. Wherein, the hardness of the inner core embryo 1 is the smallest relative to the hardness of each component of the shoe sole embryo. The upper ring embryo 2 and the lower bottom embryo 3 are clamped together. The upper ring embryo 2 has a hollow structure, and the inner kernel embryo 1 fits in the hollow part of the upper ring embryo 2 . It should be noted that, in the present invention, the inner kernel embryo 1, the upper ring embryo 2 and the lower bottom embryo 3 are all structures under the embryo body state (that is, without foaming), and further, the inner kernel...

Embodiment 2

[0083] The difference between this embodiment and the first embodiment lies in: the difference of the anti-skid lines.

[0084] Let's take the sole of the right foot as an example to illustrate. like Figure 11 As shown, the shape of the anti-skid lines 5 is linear, and the distribution density is concentrated. The anti-skid lines 5 include toe lines 51 , front horizontal and outer vertical lines 52 and heel lines 53 . Between the toe lines 51 and the front horizontal outer vertical lines 52 , as well as between the front horizontal outer vertical lines 52 and the heel lines 53 , there are blank strips without lines.

[0085] The toe lines 51 are several second curved lines extending from the outside to the inside. The inner width of the second curved lines is larger than the outer side, and the width gradually narrows from the innermost side to the outermost side. The distribution area of the toe lines 51 corresponds to the stress points and the stress areas of the toes ...

Embodiment 3

[0093] The difference between this embodiment and the first embodiment lies in: the difference of the anti-skid lines.

[0094] Let's take the sole of the right foot as an example to illustrate. like Figure 12 As shown, the shape of the anti-skid lines is scattered, and the distribution density is concentrated. The inner core is divided into an inner longitudinal area and a main area except the inner longitudinal area, the main area is provided with several arc-shaped protrusions 17 of the same shape and size.

[0095] The main area includes a forefoot area, a heel area, and a midsection area between the forefoot area and the heel area. The arc-shaped protrusions 17 have different densities in different regions. In view of the fact that when walking, the concentrated force-bearing area of the human foot is the forefoot area, and the denser arc-shaped protrusions 17 are concentrated in the fore-foot area, and then transition to a loose arrangement density in the middle se...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bump height | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com