Thermally conductive silicone sheet as well as preparation method and application thereof, and thermally conductive heating silicone sheet as well as preparation method and application thereof

A heat-conducting silica gel sheet and silica gel sheet technology, applied in the field of silica gel sheets, can solve the problems of high temperature resistance, poor hardness, and low thermal conductivity, and achieve the effects of high stability, high heating power, and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0071] According to another aspect of the present invention, there is provided a method for preparing the above-mentioned heat-conducting silica gel sheet, which includes the following steps: after uniformly mixing all raw materials, curing and molding to obtain the heat-conducting silica gel sheet. The method has a simple process and is suitable for mass production, and the prepared heat-conducting silica gel sheet has good heat-conducting performance and wide application range.

[0072] Preferably, the curing molding includes pressure curing molding. The production efficiency of pressure curing molding is high, the internal stress of the obtained product is small, the mechanical properties are relatively stable, the dimensional accuracy of the product is high, and the product consistency is good.

[0073] Preferably, the curing molding pressure is greater than 250kgfcm 2 , curing molding time is 20-30 seconds. The above curing molding pressure is typically but not limited ...

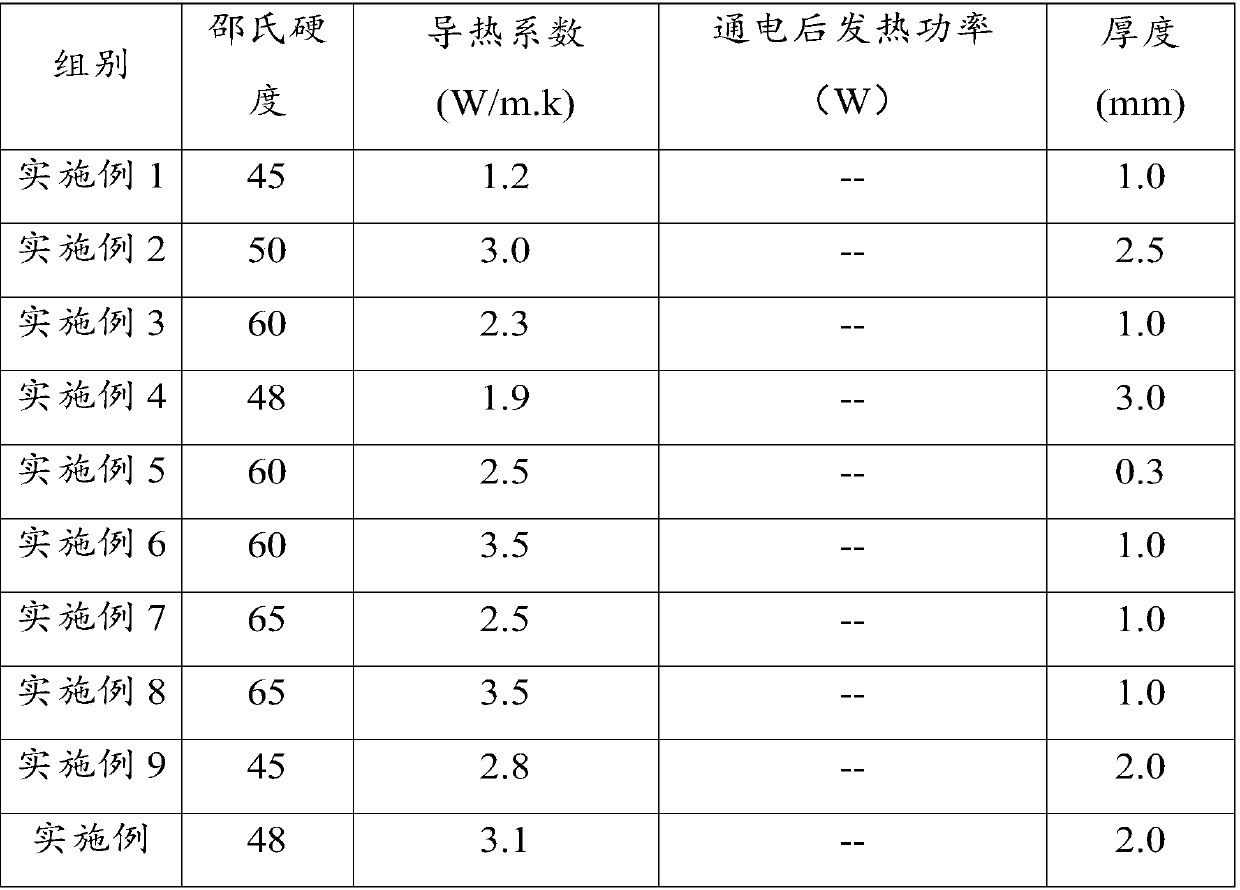

Embodiment 1

[0098] A heat-conducting silica gel sheet, prepared from the following raw materials in parts by mass: 10 parts of silicone rubber, 300 parts of aluminum oxide, 0.5 parts of aluminum hydroxide, 0.3 parts of silicon dioxide and 3 parts of hydrogen-containing silicone oil; The weight-average molecular weight is 700,000; the thickness of the heat-conducting silica gel sheet is 1.0 mm.

Embodiment 2

[0100] A heat-conducting silica gel sheet, prepared from the following raw materials in parts by mass: 100 parts of silicone rubber, 1000 parts of silicon carbide, 100 parts of aluminum oxide, 6 parts of talcum powder and 50 parts of platinum-based catalyst; the weight average of the silicone rubber The molecular weight is 900,000; the thickness of the heat-conducting silica gel sheet is 2.5mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com