Industrial dangerous waste incineration processing system for realizing multiple physical states

A hazardous waste and treatment system technology, applied in incinerators, combustion methods, combustion types, etc., can solve the problems of high temperature corrosion and low temperature corrosion of flue and heat exchange surface, operation failure of dust removal equipment, complex equipment system, etc., to avoid Low temperature corrosion, avoid high temperature corrosion, reduce the effect of pulping system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

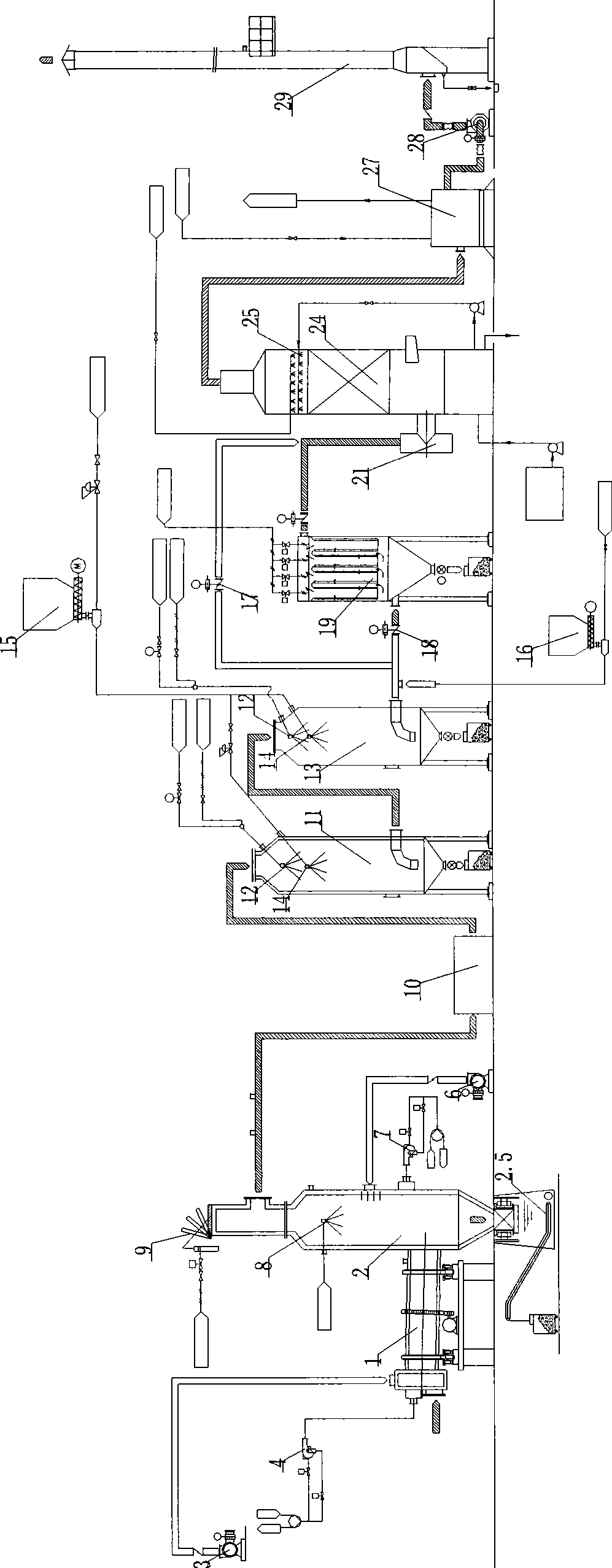

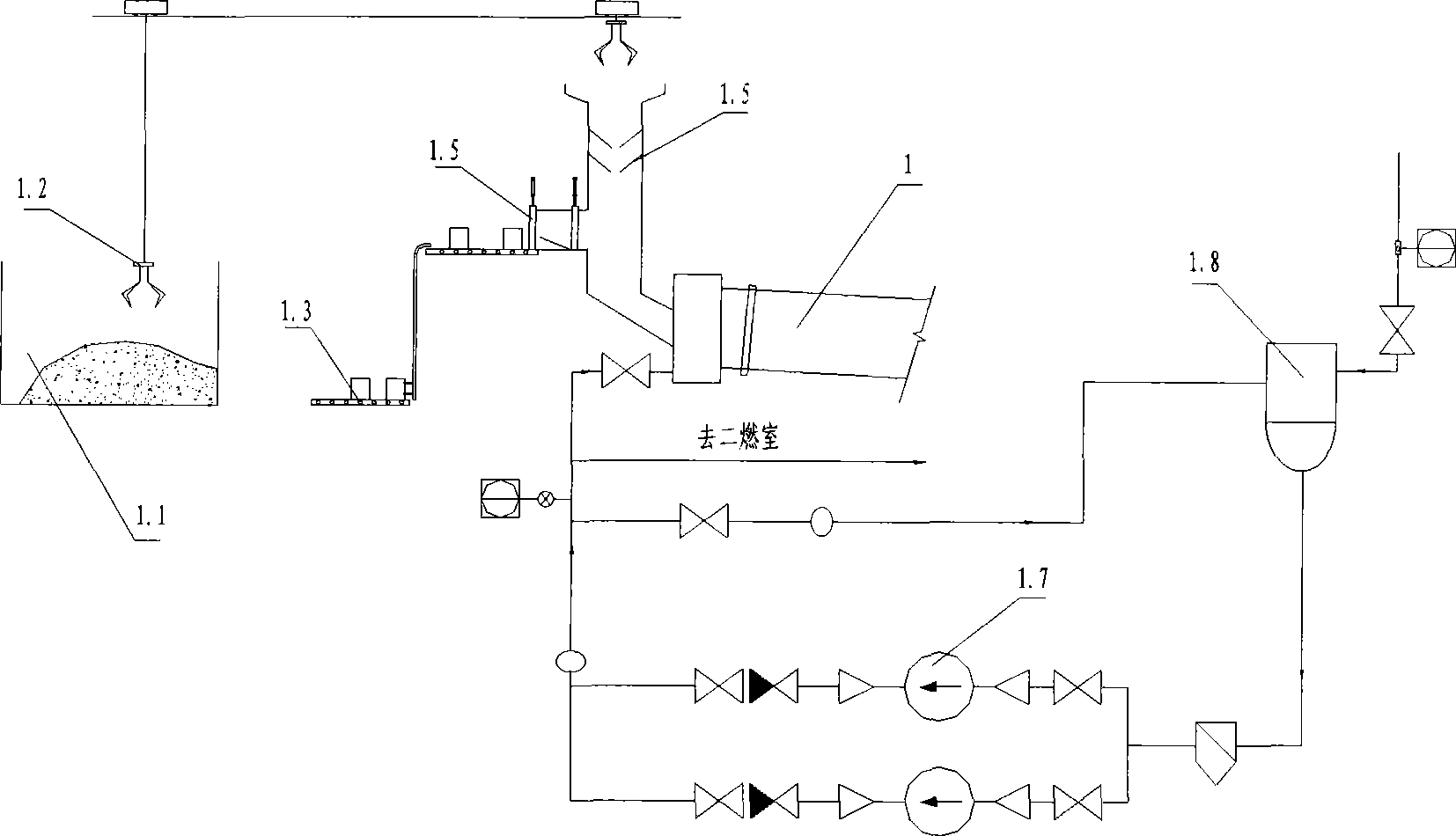

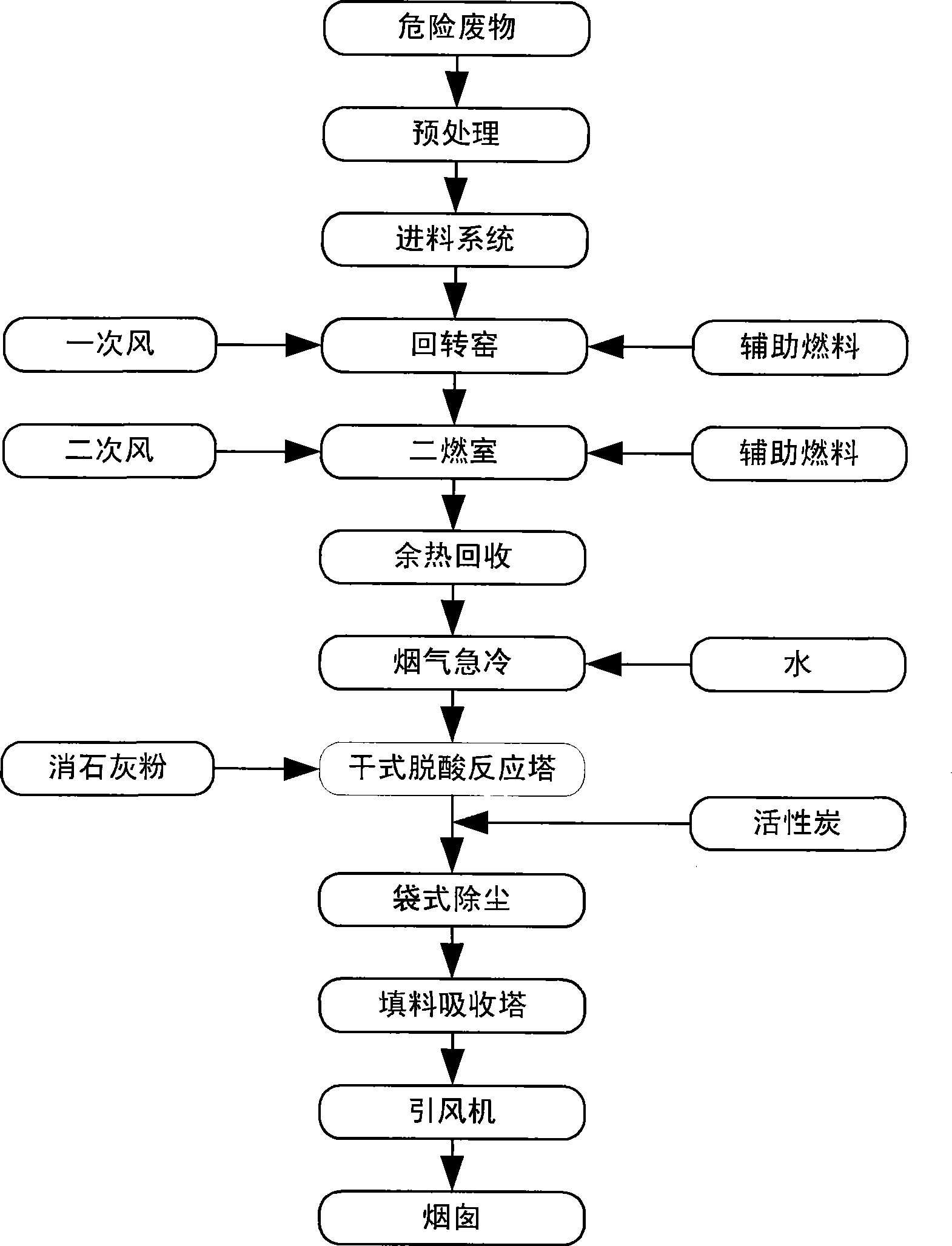

[0028] see figure 1 and figure 2 , the system of the present invention includes a feeding device composed of a bulk feeding mechanism, a barreled feeding mechanism and a waste oil conveying mechanism, an incineration device composed of a rotary kiln 1 and a second combustion chamber 2, and an incinerator connected to the second combustion chamber 2 in sequence. Waste heat boiler 10, quenching tower 11, dry deacidification reaction tower 13, bag filter 19, packing absorption tower 24, flue gas heater 27, induced draft fan 28 and chimney 29. Two airtight doors 1.5 are arranged at the bulk waste feed inlet or barreled waste feed inlet on the feed hopper of the rotary kiln 1 so that the combustion state in the kiln is under negative pressure. The frames of the rotary kiln 1 and the second combustion chamber 2 are made of carbon steel, and the refractory material of the working layer of the rotary kiln 1 is made of chrome corundum wear-resistant plastic. The refractory material ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bulk density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com