Manufacturing method of shield machine scraper

A manufacturing method and shield machine technology, applied in the direction of manufacturing tools, metal processing equipment, welding equipment, etc., can solve the problems of low welding strength, small adaptable range, wear, etc., and achieve the effect of large profits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

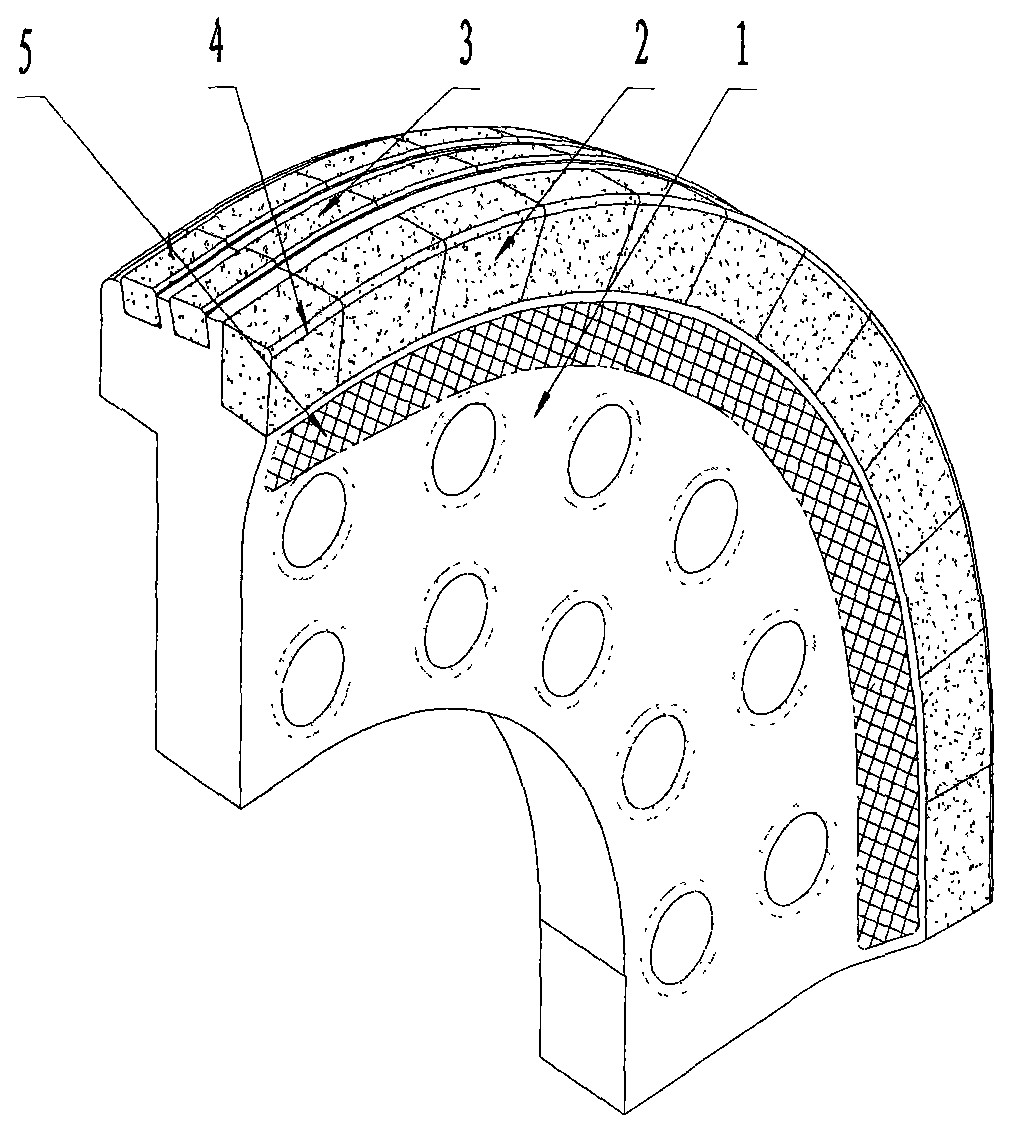

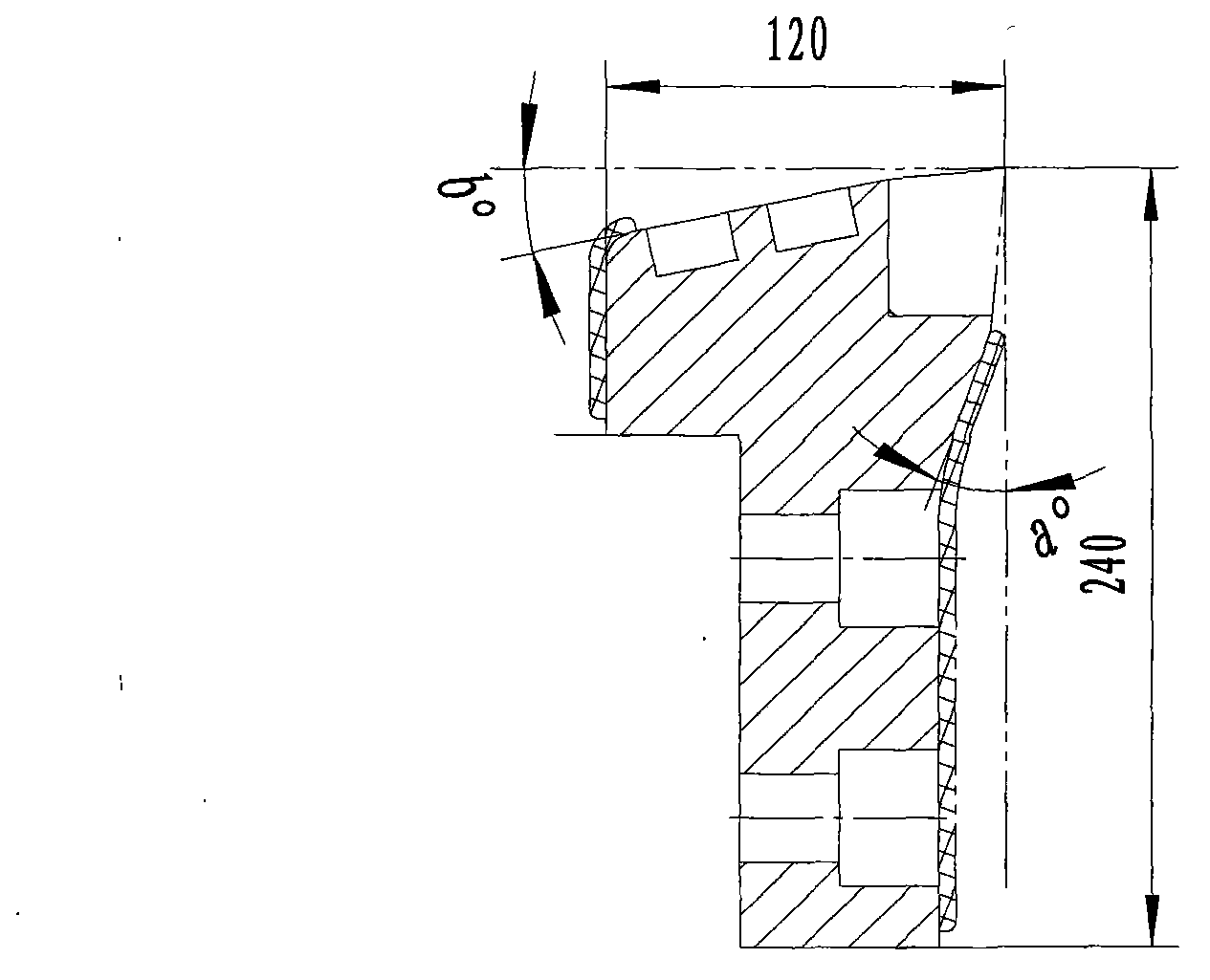

[0017] The production of the cutter body 1, as shown in the accompanying drawings, will select the required blanking amount according to the size of the drawing of the cutter body 1, and carry out die forging with a forging die to form the blank of the cutter body 1, and place the blank of the cutter body 1 Carry out annealing treatment in the heat treatment furnace, and then carry out mechanical rough machining, and then place the roughly machined cutter body 1 blank in the heat treatment furnace again, and carry out intermediate heat treatment to make its hardness at HRC40-45; side, surfacing and coating wear-resistant layer 5, and then on the CNC machine tool body 1 side, carry out mechanical precision machining to form an alloy blade step, and then process at least one U-shaped groove on the outer periphery of the cutter body 1, and braze in the U-shaped groove The auxiliary blade 3, the main blade 4 and the main blade 2 at the brazing end are sequentially brazed on the ste...

Embodiment 2

[0019] Make preparations first, choose an intermediate frequency induction heating power supply with matching power, adjust the brazing tooling, and make an open heating coil, so that the distance between the coil and the welding cutter body is 3-4mm; then according to the size of the brazing veneer Cut the appropriate size of sheet solder (the solder is a sheet made of silver, nickel, copper, zinc, cadmium and other alloy elements selected according to the characteristics of the scraper) and the stainless steel mesh pad in the middle slices; then clean the scraper body and the hard alloy blades with an ultrasonic cleaning solution for later use.

Embodiment 3

[0021] The method of preparing flow-blocking brazing flux is to select silver brazing flux and pure water in a ratio of 3:1 (cubic meter=m3) and mix thoroughly into a paste, and heat at 55°C to 60°C and stir evenly without particulate matter for use. Note that the paste flux should not be used when stratification occurs, it must be reheated and stirred evenly before use. The selection and cleaning of stainless steel mesh gaskets, select stainless steel mesh gaskets, first clean the oil stains with industrial alcohol, and then use nitric acid and water to make pickling solution at a ratio of 3:17 (% by weight) to etch and clean for 5 minutes (to remove oxidation). Membrane), in this step, the pickling solution should be prepared strictly according to the required ratio, and cleaned according to the specified time to avoid incomplete cleaning or over-corrosion. Then rinse with hot water and immediately put it into the prepared paste brazing flux to soak before use. This step mu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com