Combined type mechanically crushing machine hammer and manufacturing method thereof

A combined type and crusher technology, which is applied in the direction of manufacturing tools, casting molding equipment, casting mold components, etc., can solve the problems of wasting hammer handle metal materials, difficulty in recycling and remelting, and high labor intensity, and achieves convenient recycling and remelting. The effect of solving the harsh production environment and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

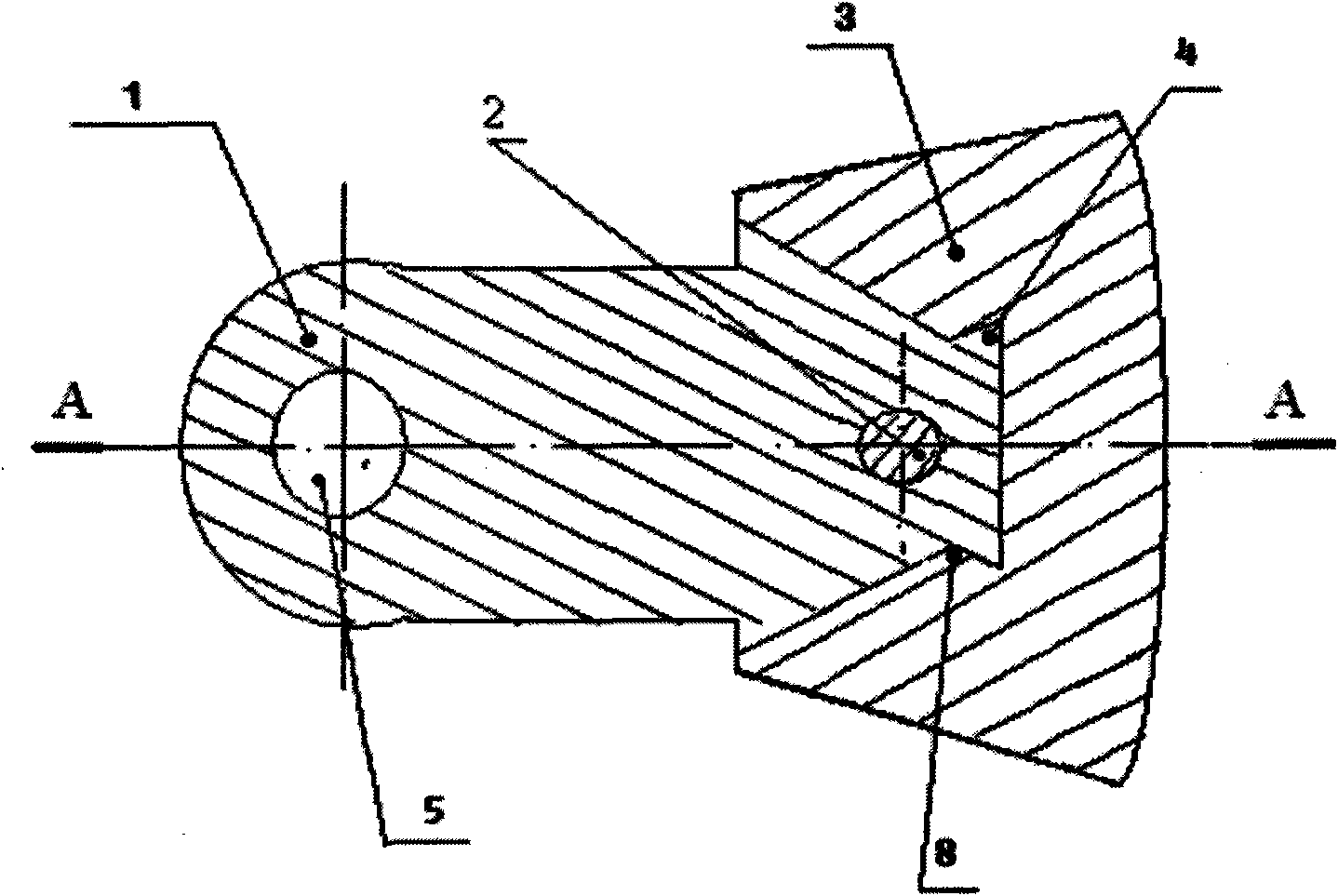

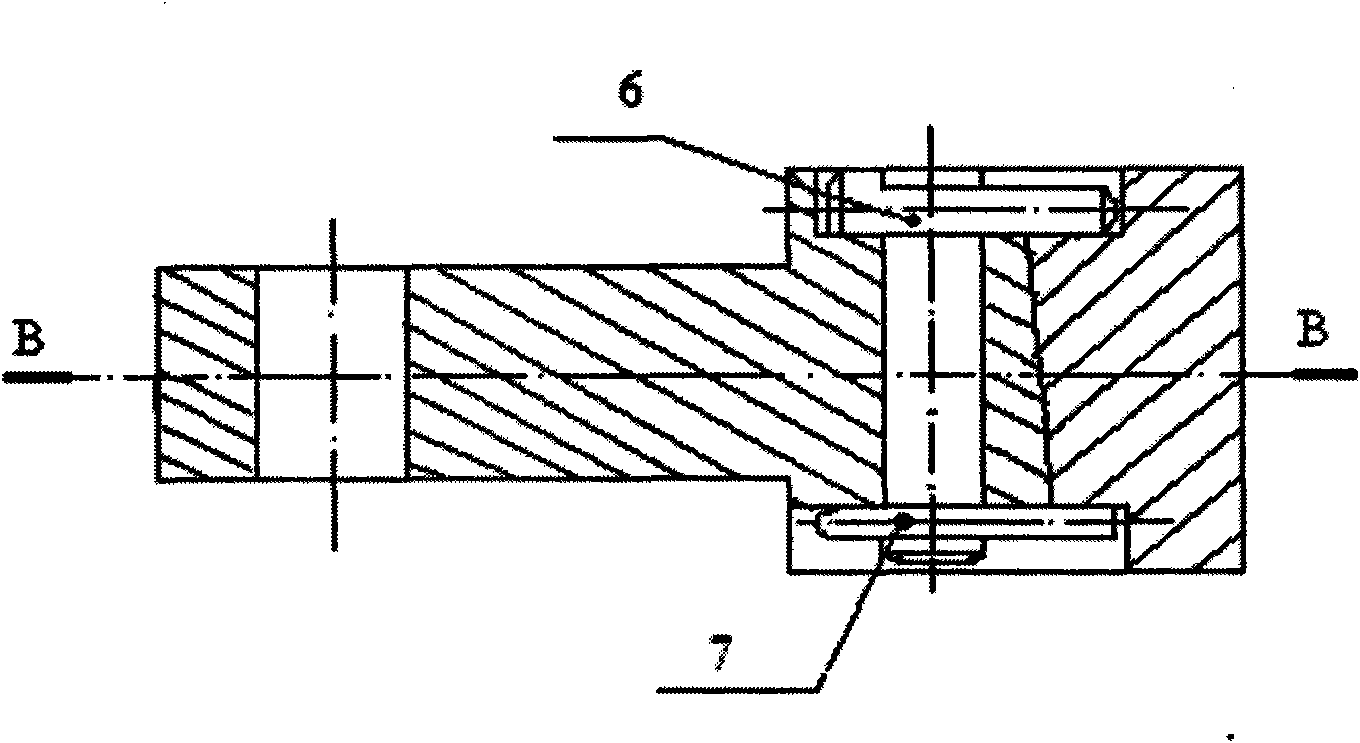

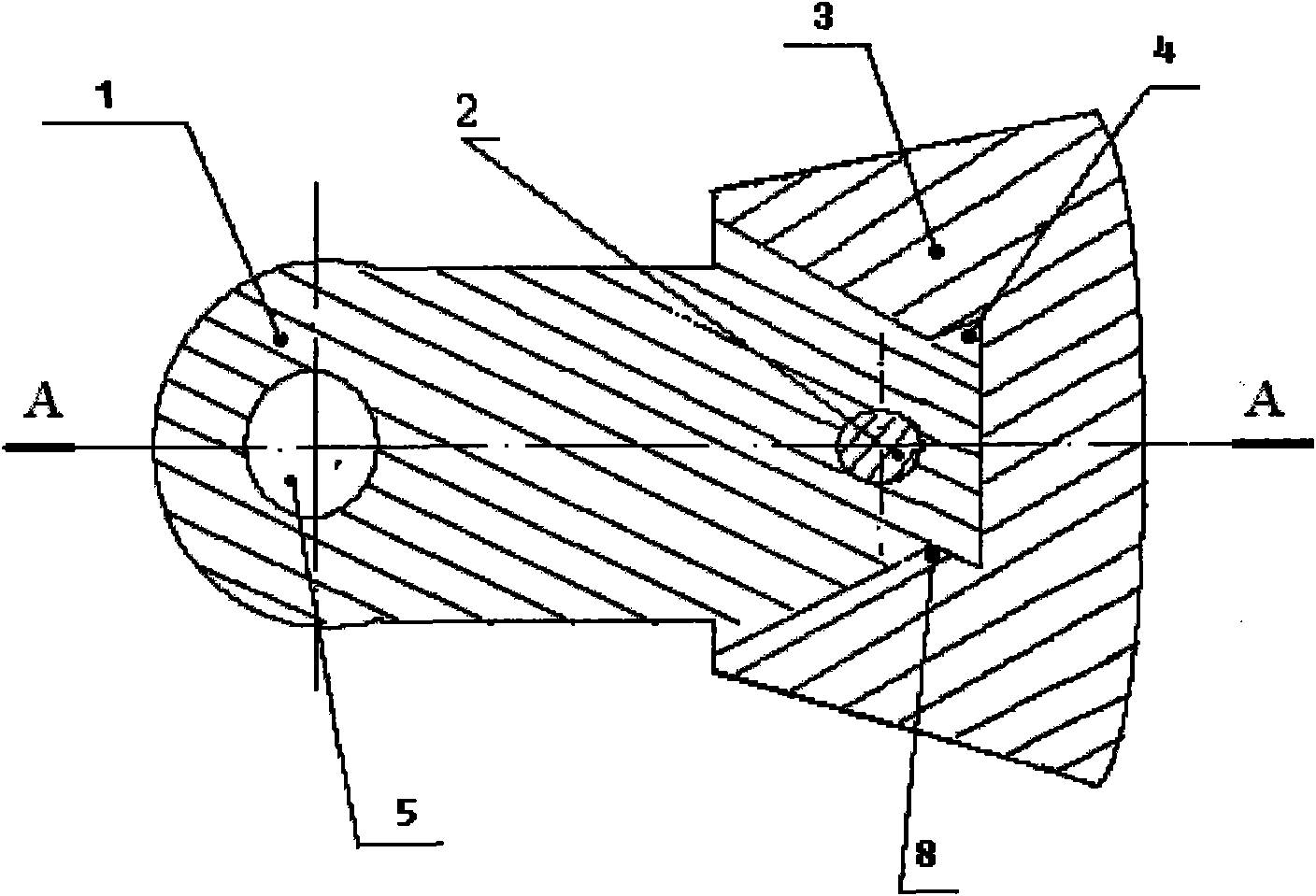

Image

Examples

Embodiment 1

[0030] Embodiment 1: Production of a hammer head with a unit weight of 350N. The head of the hammer head is made of high-chromium cast iron lost foam casting. The mass fraction of the chemical composition of the high-chromium cast iron is: C 2.92%, Si 0.56%, S 0.03 %, P 0.04%, Mn 0.81%, Cu 0.48%, Cr 24.27%, Mo 0.42%, V 0.12%, W 0.56%, RE 0.092%, Fe 69.698%.

[0031] The shank of the hammer head is made of high manganese steel lost foam casting. The mass fraction of high manganese steel chemical composition is: C 1.16%, Mn 13.06%, Si 0.52%, Cr 1.91%, S 0.03%, P 0.04% , RE 0.19%, Fe 83.09%;

[0032] The manufacturing method of hammer head of the present invention is: this manufacturing method comprises the production process of head high chromium cast iron and shank high manganese steel, lost foam casting process and heat treatment process and the mechanical assembly process of hammer head; Wherein, the high chromium cast iron The production process is as follows: put ordinary ...

Embodiment 2

[0038] Embodiment 2: the production of a hammer head with a unit weight of 250N, the head of the hammer head is cast from high-chromium cast iron, and the mass fractions of the chemical composition of the high-chromium cast iron are: C3.12%, Si 0.66%, S 0.04% , P 0.06%, Mn 1.07%, Cu 0.57%, Cr 25.82%, Mo 0.54%, V 0.18%, W 0.67%, RE 0.12%, Fe 67.15%.

[0039] The handle of the hammer head is cast from high manganese steel. The mass fraction of chemical composition of high manganese steel is: C 1.19%, Mn 13.56%, Si 0.69%, Cr 2.23%, S 0.03%, P 0.06%, RE 0.21%, Fe 82.03%;

[0040] The manufacturing method of hammer head of the present invention, this manufacturing method comprises the production process of head high chromium cast iron and shank high manganese steel, lost foam casting process and heat treatment process and the mechanical assembly process of hammer head; Wherein, the production of high chromium cast iron The process is as follows: Add ordinary steel scrap and pig ir...

Embodiment 3

[0047] Embodiment 3: the production of a hammer head with a unit weight of 150N, the head of the hammer head is cast from high-chromium cast iron, and the mass fractions of the chemical composition of the high-chromium cast iron are: C3.28%, Si0.74%, S0.05% , P 0.07%, Mn 1.22%, Cu 0.69%, Cr 26.76%, Mo 0.63%, V 0.21%, W 0.75%, RE 0.13%, Fe 65.47%.

[0048] The shank of the hammer head is cast from high manganese steel. The mass fraction of chemical composition of high manganese steel is: C 1.27%, Mn 14.28%, Si 0.84%, Cr 2.43%, S 0.05%, P 0.06%, RE 0.25%, Fe 80.82%;

[0049]The manufacturing method of hammer head of the present invention, this manufacturing method comprises the production process of head high chromium cast iron and shank high manganese steel, lost foam casting process and heat treatment process and hammer head assembly process; Wherein, the production process of high chromium cast iron Method: add ordinary steel scrap and pig iron into the intermediate frequenc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com