Preparation method of 80-100mm extra-thick EH36 steel for offshore wind power

An offshore wind power, extra-thick technology, applied in the field of iron and steel metallurgy, can solve the problems of increasing production time and economic cost, increasing the cost of normalizing process, increasing the cost of alloy, etc., to achieve the goal of suppressing crack tendency, improving welding performance and improving uniformity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

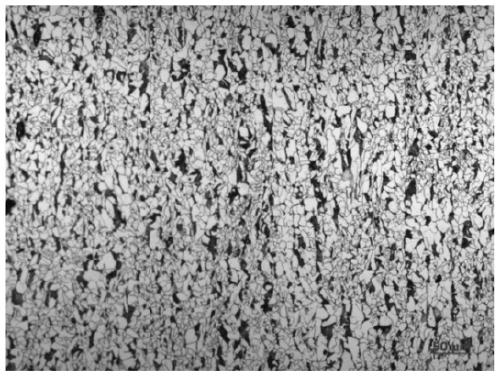

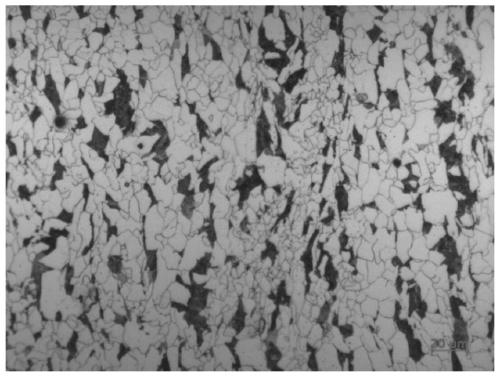

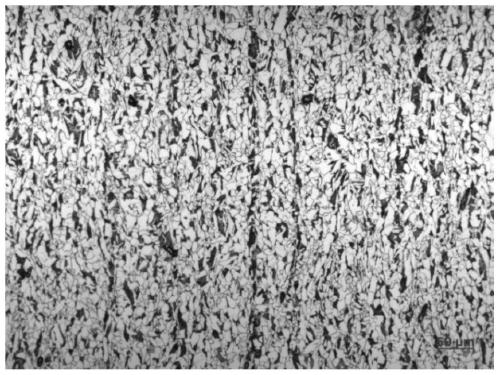

Image

Examples

preparation example Construction

[0045] The preparation method of the extra-thick offshore wind power EH36 steel of the embodiment 1-6 of the present invention comprises the following steps:

[0046] (1) Smelting: use a 150-ton converter for smelting, then send it to an LF furnace for refining and RH vacuum degassing treatment, and perform Ca treatment by breaking through the air. The composition control is shown in Table 1.

[0047] (2) Continuous casting: cast the smelted molten steel into a continuous casting slab with a thickness of 370 mm. The casting temperature is controlled at 10-25°C above the liquidus, that is, the degree of superheat is 10-25°C. During the casting process, dynamic soft pressure reduction and argon protection are implemented.

[0048] (3) Slab hydrogen expansion treatment: continuous casting slabs are stacked in the pit for slow cooling and hydrogen expansion, and the time in the pit is 72 hours. The slow cooling start temperature is required to be ≥600°C.

[0049] (4) Heating: P...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| carbon equivalent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com