Forming method for thin-wall changeable thickness composite antenna cover

A molding method and composite material technology, applied in the direction of radiation unit outer cover, household components, household appliances, etc., to achieve the effect of increasing interlayer shear strength, low manufacturing cost, and good appearance quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

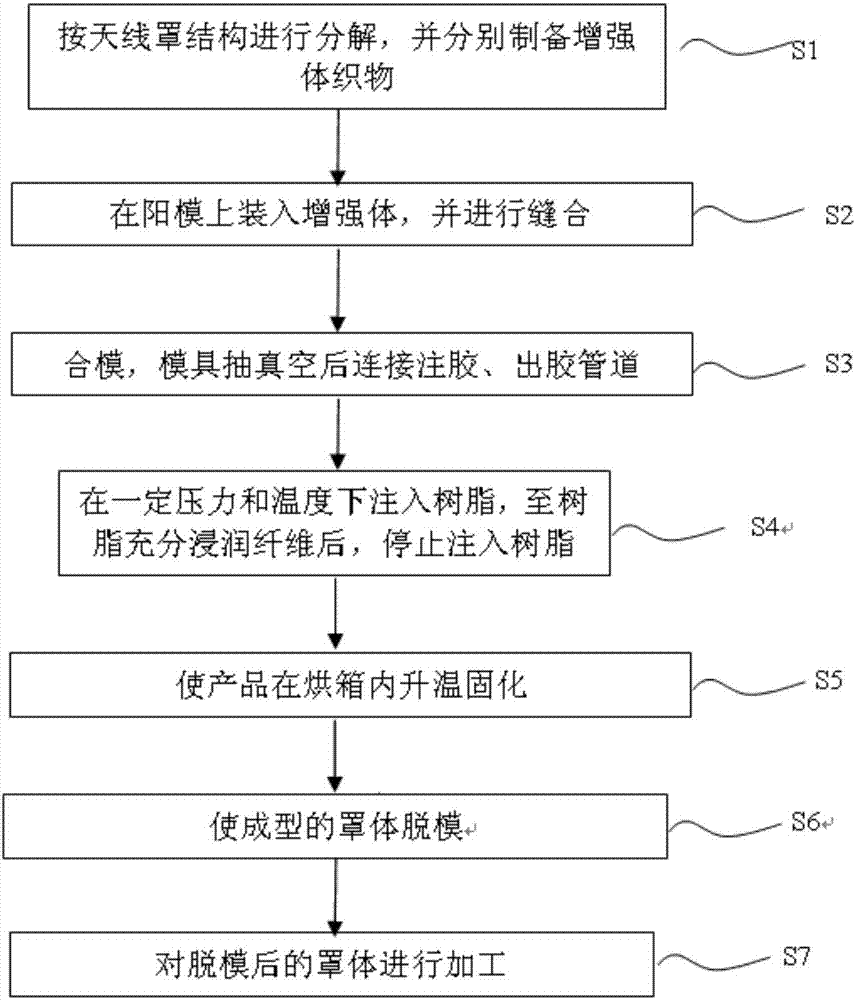

[0041] Such as figure 2 As shown, the molding method of the thin-wall variable thickness composite material radome of the present invention comprises the following steps:

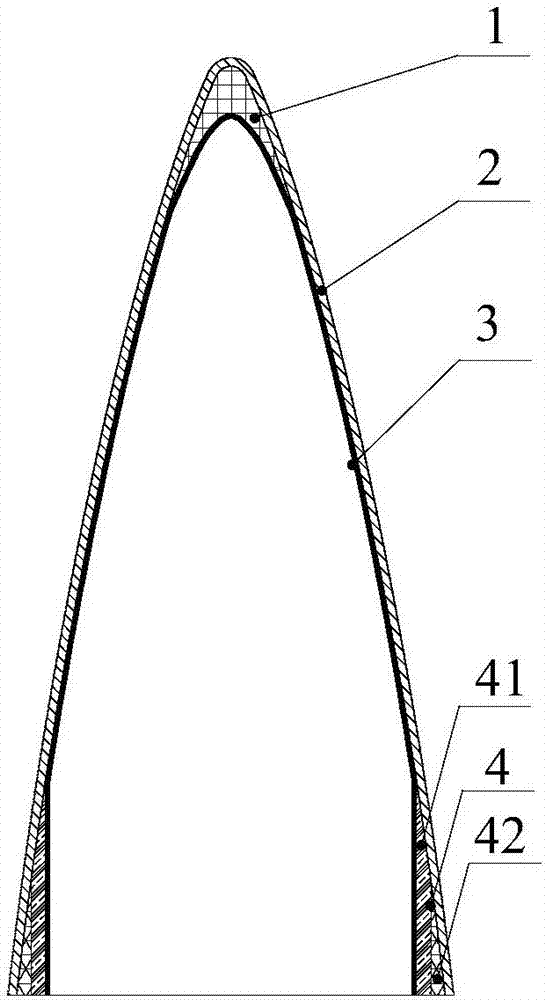

[0042] S1, decompose according to the structure of the radome, and prepare the reinforcement fabric respectively: according to the structure of the radome, divide the wall of the radome into an equal-thickness area and a variable-thickness area, and prepare reinforcement fabrics of different structures (top variable-thickness reinforcement Body 1, outer equal-thickness reinforcing body 2, inner equal-thickness reinforcing body 3 and root variable-thickness reinforcing body 4);

[0043] S2. Put reinforcements on the male mold and sew them up: put the reinforcement fabric into the male mold of the forming mold, and sew them together with yarn;

[0044] S3, close the mold, connect the glue injection and glue outlet pipes after the mold is vacuumed;

[0045] S4. Inject glue under a certain pressure and tempera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com