A kind of silicon carbon negative electrode slurry and preparation method thereof

A negative electrode slurry, silicon carbon technology, applied in the direction of battery electrodes, structural parts, electrical components, etc., can solve the problems that the electrochemical performance of active materials cannot be exerted, unfavorable cost control, loss of electrical connection, etc., to achieve improved adhesion effect, improve electrical conductivity, reduce expansion and shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

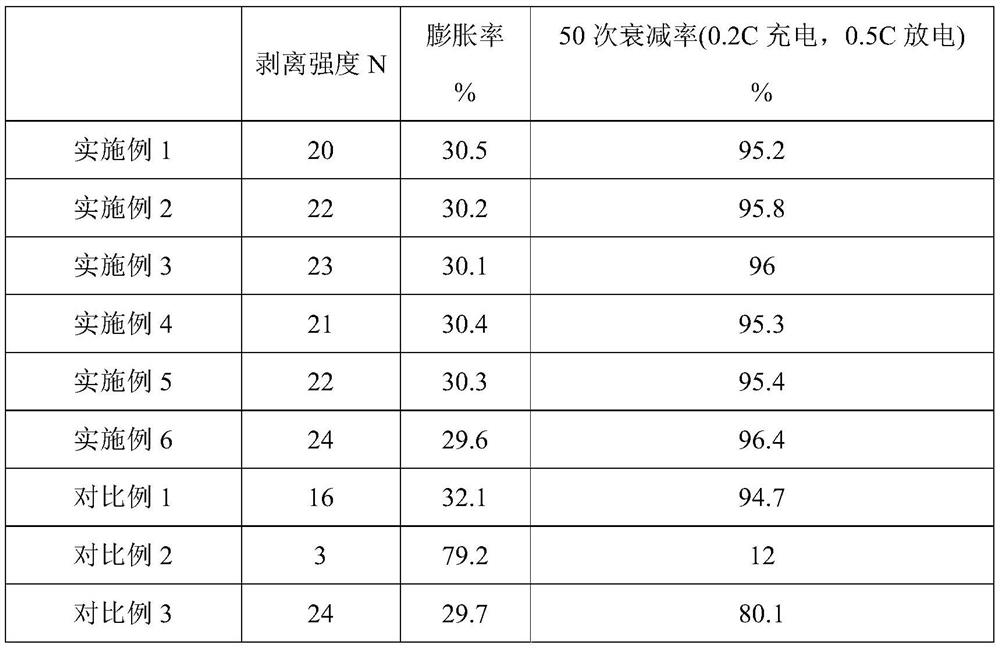

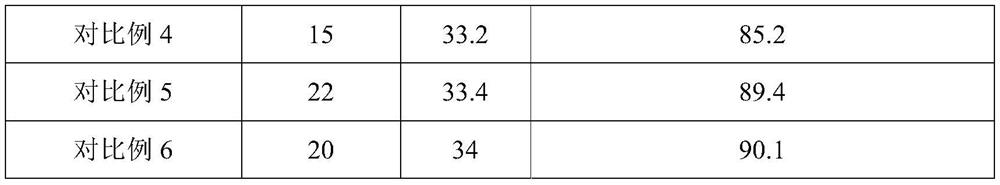

Examples

Embodiment 1

[0068] This embodiment provides a silicon-carbon negative electrode slurry, which contains the following components in terms of mass percentage: 94.9% silicon-based / graphite mixture, 2% binder, single-walled carbon nano Tube 1%, carbon black 0.1%, coupling agent 2%;

[0069] Wherein, the binder is a polyacrylic acid-based polymer containing carboxyl functional groups, and the monomer of the polymer contains more than 3 hydroxyl groups, and the molecular weight is greater than 10000; the carbon black is conductive carbon black (Super-p), The particle size is 0.1-2 μm; the diameter of the single-walled carbon nanotube is 0.6-10 nm, and the tube length is 5-30 μm; the silicon base in the silicon-based / graphite mixture is silicon oxide-coated carbon; the graphite is artificial Graphite; the coupling agent is a silane coupling agent.

[0070] Prepare the above silicon carbon negative electrode slurry according to the following method:

[0071](1) Carry out dry mixing with silicon...

Embodiment 2

[0078] This embodiment provides a silicon-carbon negative electrode slurry, which contains the following components in terms of mass percentage: 93.7% silicon-based / graphite mixture, 6% binder, single-walled carbon nano Tube 0.1%, carbon black 0.1%, coupling agent 0.1%;

[0079] Wherein, the binder is a polyacrylic acid-based polymer containing carboxyl functional groups, and the monomer of the polymer contains more than 3 hydroxyl groups, and the molecular weight is greater than 10000; the carbon black is conductive carbon black (Super-p), The particle size is 0.1-2 μm; the diameter of the single-walled carbon nanotube is 0.6-10 nm, and the tube length is 5-30 μm; the silicon base in the silicon base / graphite mixture is silicon alloy coated carbon; the graphite is a natural coating Graphite-coated; the coupling agent is a titanate coupling agent.

[0080] Prepare the above silicon carbon negative electrode slurry according to the following method:

[0081] (1) Carry out dry...

Embodiment 3

[0088] This embodiment provides a silicon-carbon negative electrode slurry, which contains the following components in terms of mass percentage: 96% silicon-based / graphite mixture, 2% binder, single-walled carbon nano Tube 0.1%, carbon black 0.1%, coupling agent 0.8%;

[0089] Wherein, the binder is a polyacrylic acid-based polymer containing carboxyl functional groups, and the monomer of the polymer contains more than 3 hydroxyl groups, and the molecular weight is greater than 10000; the carbon black is conductive carbon black (Super-p), The particle size is 0.1-2 μm; the diameter of the single-walled carbon nanotube is 0.6-10 nm, and the tube length is 5-30 μm; the silicon base in the silicon-based / graphite mixture is nano-silicon-coated carbon; the graphite is a natural coating Graphite-coated; the coupling agent is a titanate coupling agent.

[0090] Prepare the above silicon carbon negative electrode slurry according to the following method:

[0091] (1) Carry out dry m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com