Negative electrode active material for electrical device, and electrical device in which said material is used

A technology for negative active materials and electrical equipment, applied in the direction of active material electrodes, negative electrodes, electrical components, etc., can solve problems such as large expansion and contraction, reduced electrode cycle life, and difficulty in improving cycle durability

Active Publication Date: 2019-02-05

NISSAN MOTOR CO LTD

View PDF10 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0008] However, in a lithium ion secondary battery using a material alloyed with Li for the negative electrode, the expansion and contraction of the negative electrode during charge and discharge are large.

For example, the volume expansion when Li ions are absorbed is approximately 1.2 times for graphite materials. On the other hand, for Si materials, when Si and Li are alloyed, the transition from an amorphous state to a crystalline state occurs. Large volume change (about 4 times), so there is a problem that the cycle life of the electrode is reduced

In addition, in the case of the Si negative electrode active material, there is a trade-off relationship between capacity and cycle durability, and there is a problem that it is difficult to improve cycle durability while exhibiting high capacity.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 2

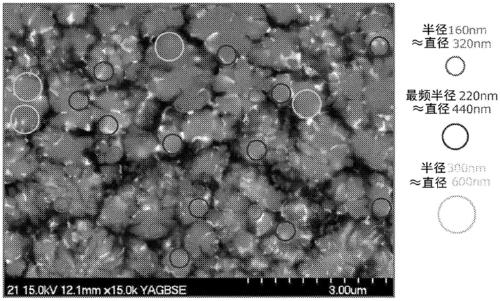

[0244] Si 64。0 sn 4.9 Ti 30.0 al 1.1 (Example 3)

Embodiment 3

[0245] Si 64.6 sn 5.0 Ti 29.8 al 0.6 (Example 4)

Embodiment 8

[0250] Si 65.0 sn 5.0 Ti 30.0 (comparative example 1)

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Login to View More

Abstract

The invention aims to provide a means with which it is possible to improve cycle durability in an electrical device such as a lithium-ion secondary cell. There is used, in an electrical device, a negative electrode active material comprising an Si-containing alloy having a composition represented by chemical formula (1): SixSnyMzAlwAa (where M is one or more transition metal elements; A is unavoidable impurities; and x, y, z, w, and a represent mass% values , where y, z, and w are respectively 2 <= y <= 10, 25 <= z <= 35, and 0.3 <= w <= 3, and x and a are remainders). The composition containsSi-containing alloy.

Description

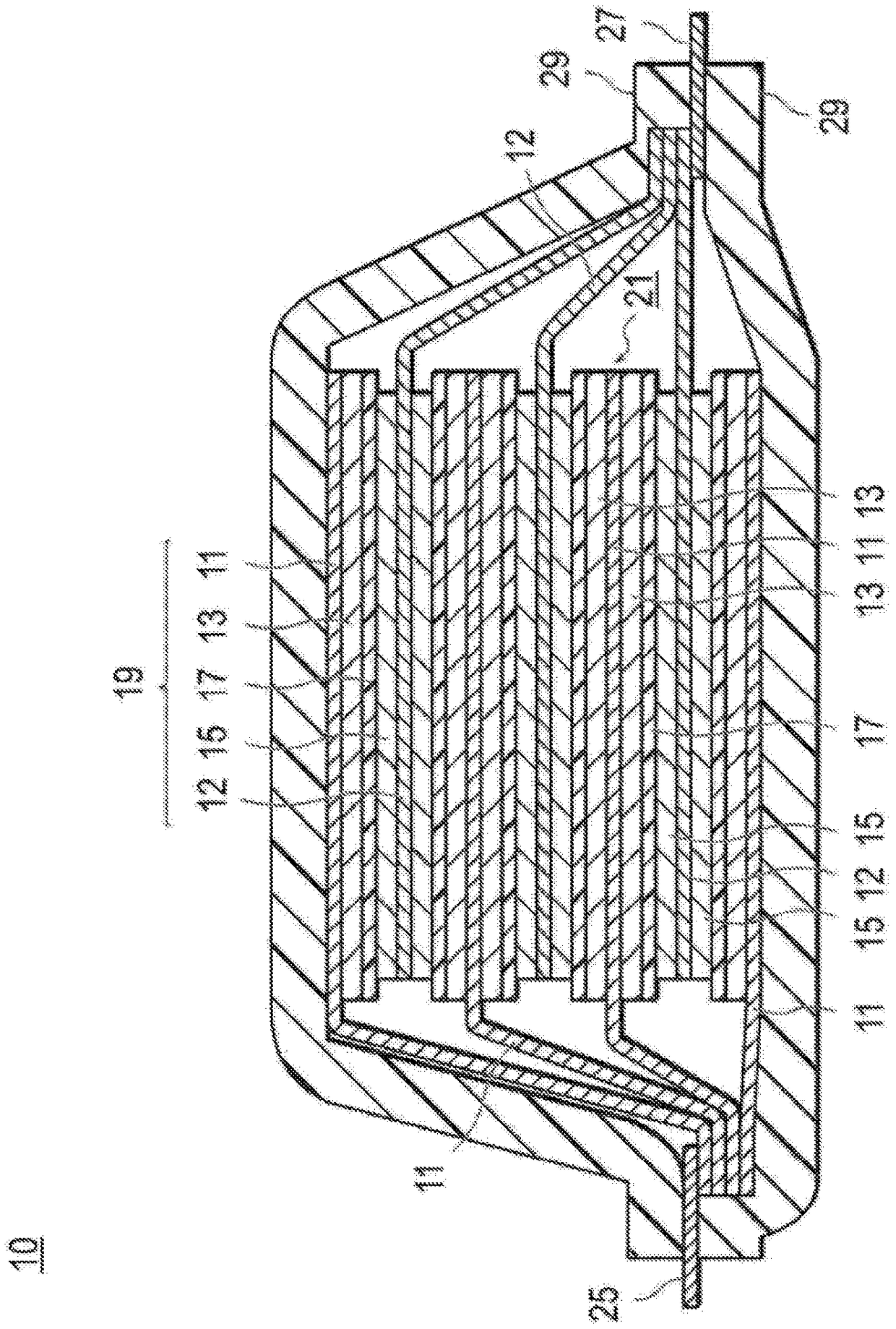

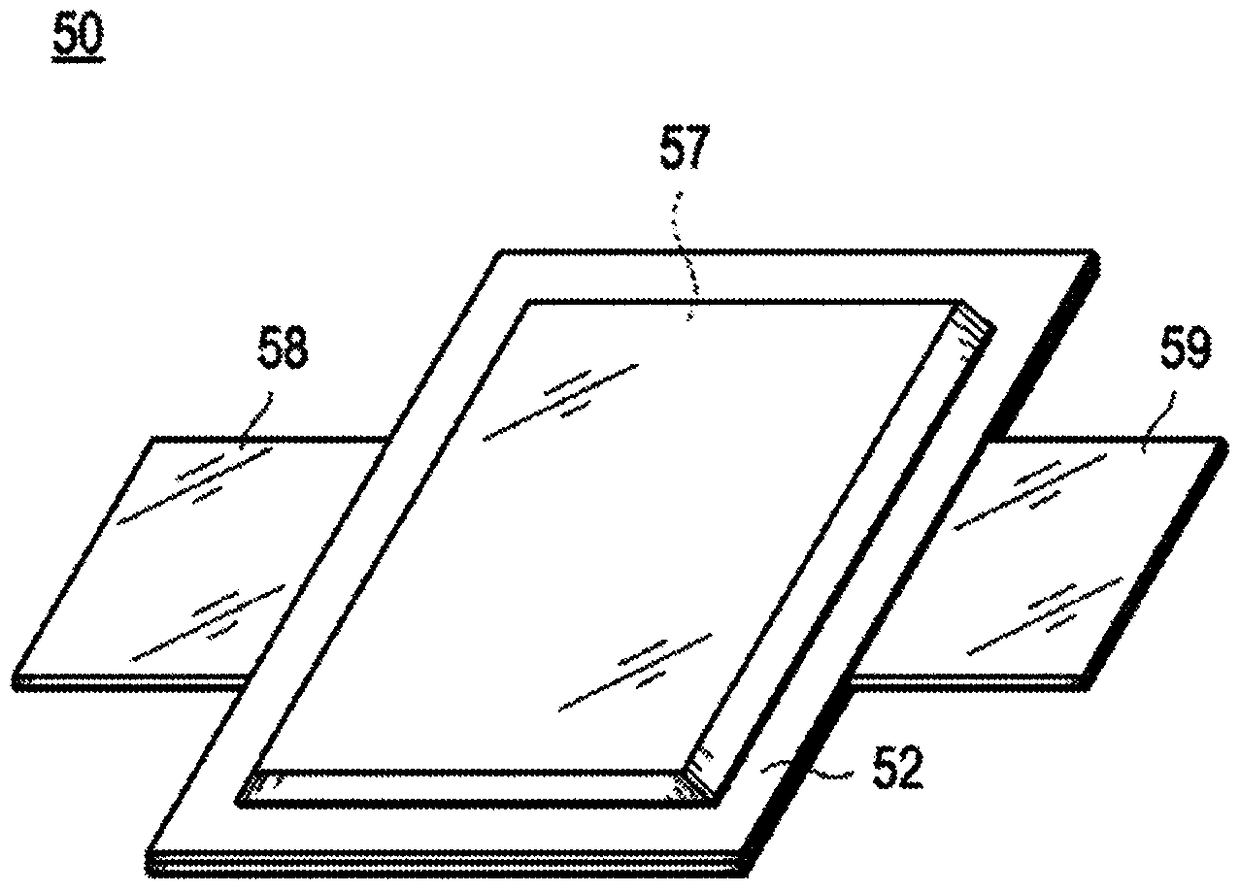

technical field [0001] The present invention relates to a negative electrode active material for electric equipment and an electric equipment using the same. The negative electrode active material for electrical equipment of the present invention and electrical equipment using the same are used, for example, as secondary batteries, capacitors, etc., as driving power sources and auxiliary power sources for engines of vehicles such as electric vehicles, fuel cell vehicles, and hybrid electric vehicles. Background technique [0002] In recent years, in order to cope with air pollution and global warming, reduction of the amount of carbon dioxide has been strongly desired. In the automotive industry, the introduction of electric vehicles (EVs) and hybrid electric vehicles (HEVs) is expected to reduce carbon dioxide emissions, and the development of electrical equipment such as secondary batteries for driving engines, which is the key to grasping their practical application, is a...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): H01M4/38C01B33/06

CPCC22C28/00C01P2002/85C01P2004/03C01P2004/04H01M10/0525H01M4/134H01M4/386Y02E60/10H01M4/38H01M2004/027

Inventor 荒井诚也千叶启贵吉冈洋一渡边学

Owner NISSAN MOTOR CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com