Negative electrode active material for electrical equipment and electrical equipment using same

A technology for negative active materials and electrical equipment, applied in the direction of active material electrodes, negative electrodes, electrical components, etc., can solve the problems of reduced electrode cycle life, large expansion and contraction of negative electrodes, etc., achieve reduced expansion and contraction, and improve cycle durability and hardness and the effect of excellent electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

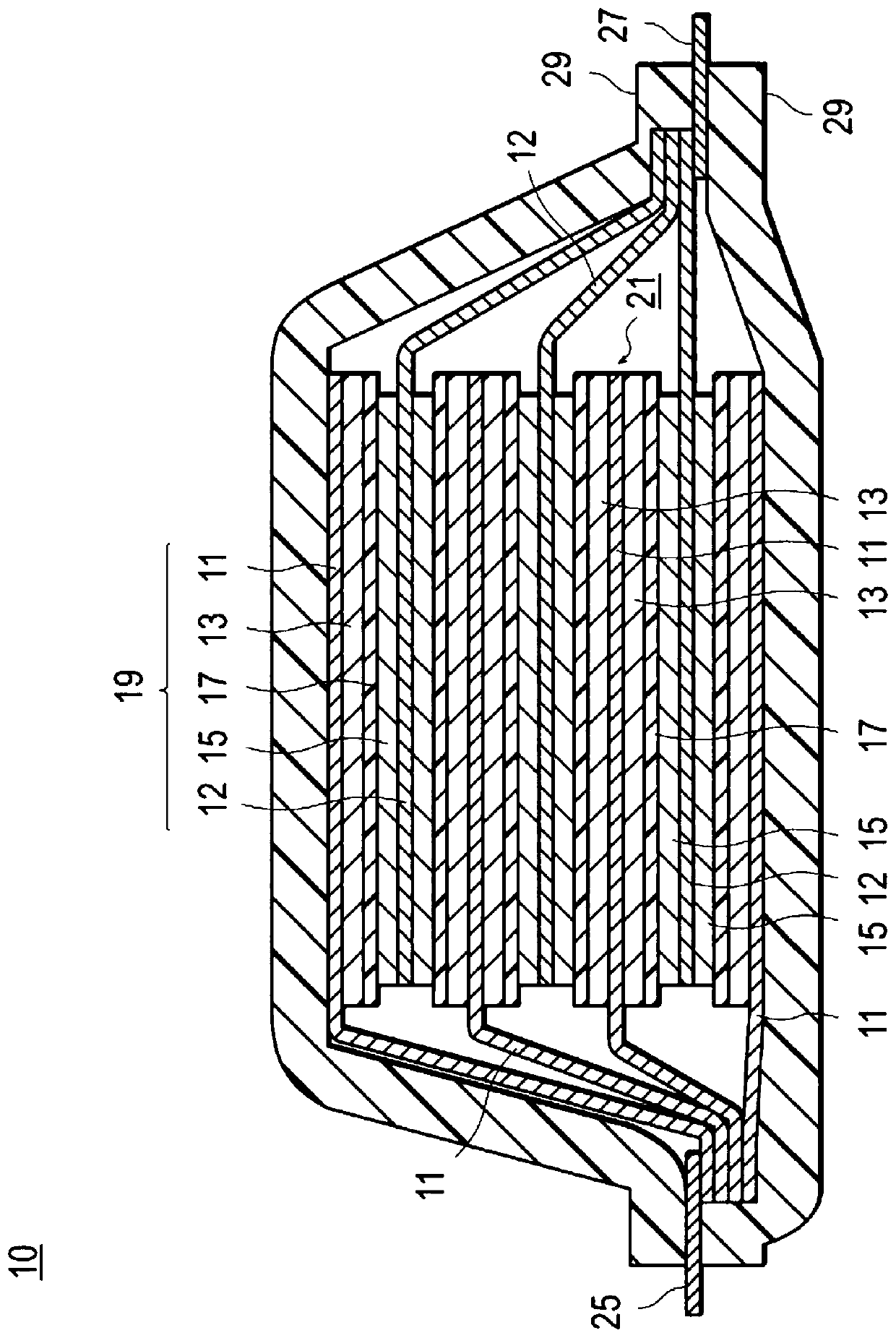

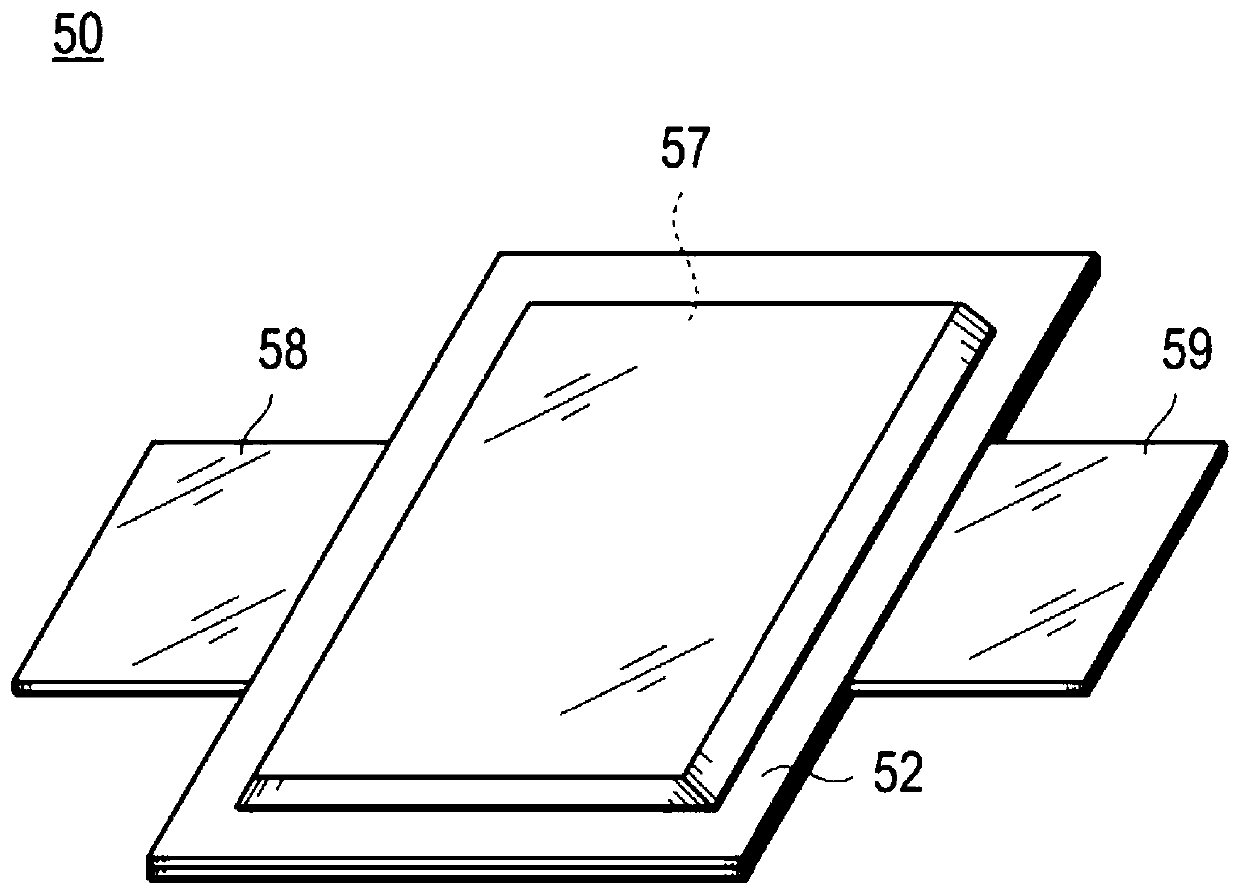

[0066] figure 1 It is a schematic cross-sectional view schematically showing the overall structure of a flat (laminated type) lithium ion secondary battery (hereinafter also simply referred to as "laminated battery"), which is a representative embodiment of the electric device of the present invention.

[0067] like figure 1 As shown, the laminated battery 10 of the present embodiment has a structure in which a substantially rectangular power generating element 21 that actually undergoes charge and discharge reactions is sealed inside a laminated sheet 29 serving as an outer package. Here, the power generating element 21 has a structure in which a positive electrode having a positive electrode active material layer 15 disposed on both surfaces of a positive electrode current collector 12, an electrolyte layer 17, and a negative electrode current collector 11 having a negative electrode active material layer 13 disposed on both surfaces thereof are configured. The negative e...

Embodiment 2~4

[0193] Si 60 sn 20 Ti 20 (comparative example 1)

[0194] Matrix / precipitated phase: Liquid / TiSi 2 、Si(diamond_A4)

[0195] (crystallization in liquid phase)

[0196] Nuclear growth model: Simplified (simplified)

[0197] Nucleation site: bulk (bulk) (also denoted as TiSi 2 , Si(dia))

[0198] Surface Energy: Use the value inferred from the Thermodynamics DB

[0199] Phase boundaries / mobility: using data from Kinetics DB

[0200] Volume of parent phase / precipitated phase: both 1E-4 (1×10 -4 )m 3 .

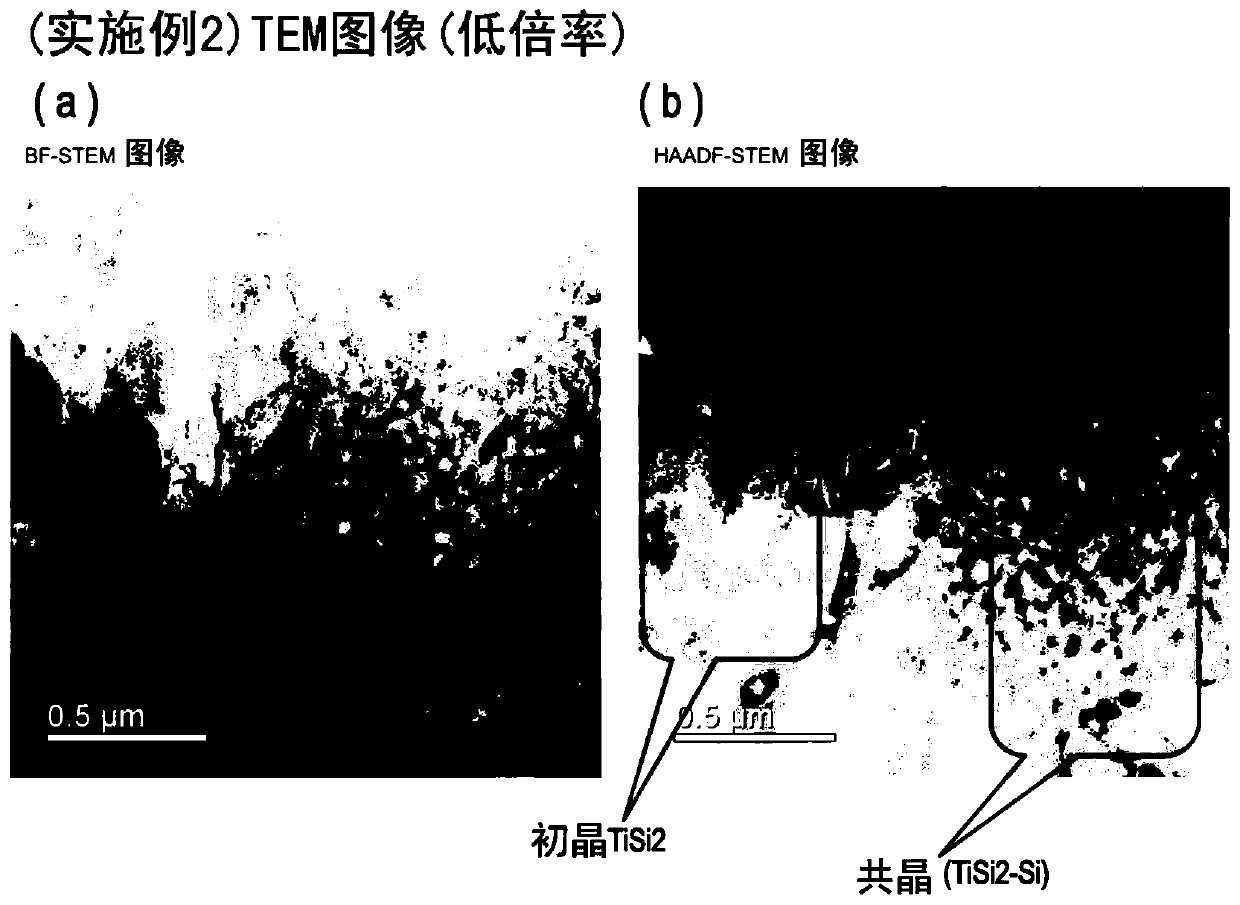

[0201] here, Figure 21 The temperature curve of is obtained as follows. Figure 19 It is a drawing showing the state of observation of the temperature of the quenched ribbon alloy obtained by the apparatus used for the liquid chill roll solidification method using an infrared temperature recorder. Specifically, the master alloys (master alloys of Examples 1 to 4) were sprayed on a Cu On the roll, the temperature of the thin strip-shaped alloy continuously formed hor...

Embodiment 1

[0292] [Manufacture of silicon-containing alloy]

[0293] Set alloy type to Si 65 sn 5 Ti 30 , made by liquid quenching and solidification method. The details will be described below. Specifically, Si alloys (65% by mass of Si, 5% by Sn of % by mass, Ti is 30% by mass) ingot alloy. The ingot alloy is pulverized so that it can be easily thrown into a quartz nozzle, and is coarsely pulverized to a diameter of about 2 mm.

[0294] Next, using the coarsely pulverized ingot alloy powder as a master alloy, a ribbon-shaped alloy = quenched ribbon alloy is produced as a silicon-containing alloy by a liquid quench solidification method. Specifically, using Nisshin Giken Co., Ltd. NEV-A05 type liquid quenching and solidification apparatus, Si was injected into a quartz nozzle installed in a chamber decompressed to gauge pressure -0.03 MPa after Ar replacement. 65 sn 5 Ti30 The master alloy is melted by high-frequency induction heating. Thereafter, it was sprayed onto a Cu roll ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com