High density poly propylene (PP) composite material

A technology of high-density polypropylene and composite materials, applied in the field of composite materials, can solve the problems of brittleness, difficult processing, high injection temperature, etc., and achieve the effect of high surface gloss, excellent wear resistance and good hand feeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

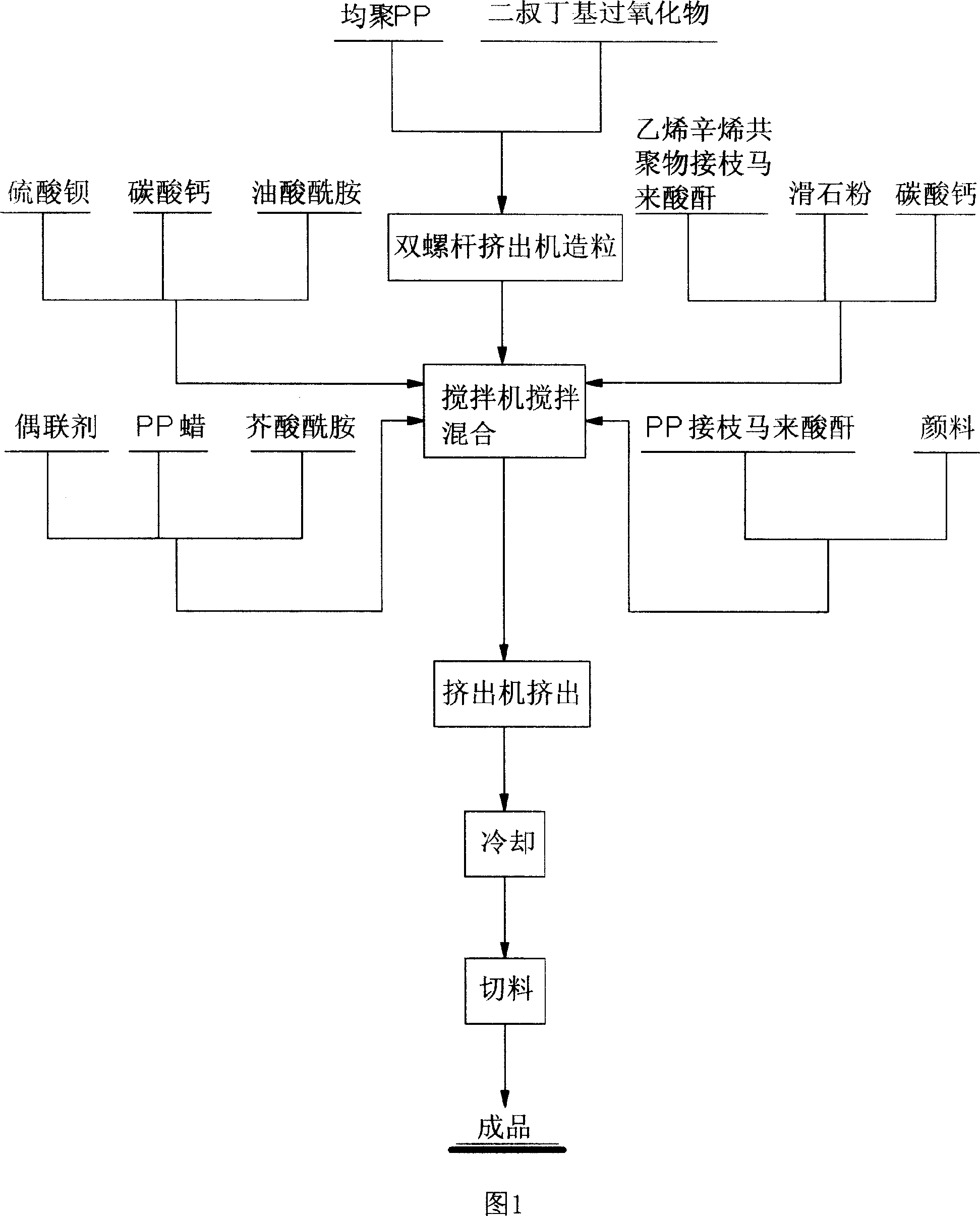

Method used

Image

Examples

Embodiment Construction

[0008] The following are the best examples of the high-density polypropylene (PP) composite material described in the present invention, which does not limit the protection scope of the present invention.

[0009] Implementation 1, a high-density polypropylene (PP) composite material is provided, which is composed of the following components by weight ratio, homopolymer PP: 13.2%, barium sulfate: 71%, talcum powder: 3%, PP-g-MAH: 6%, POE-g-MAH: 2%, molecular weight modifier: 1.0%, oleic acid amide: 0.5%, erucic acid amide: 1.5%, PP wax: 1.0%, coupling agent: 0.8%. Its melt flow rate is 160g / min and its density is g / cm 3 .

[0010] The homopolymerized PP can adopt CJS700, S700, Z30S and other grades of China Petrochemical Corporation; the particle size of barium sulfate is 1000 mesh-3000 mesh; the talcum powder is 1250 mesh; PP-g-MAH is PP grafted horse Maleic anhydride, the grafting rate is 0.8%; POE-g-MAH is ethylene octene copolymer grafted with maleic anhydride, the graft...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com