High-temperature inner formation method of power type lead-acid storage battery

A lead-acid battery, the technology of internalization, applied in the direction of lead-acid battery electrodes, etc., can solve the problems of uniform formation of positive plates, difficult battery, positive plate whitening phenomenon, etc., to improve charge conversion efficiency, high lead dioxide content, battery The effect of long cycle life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

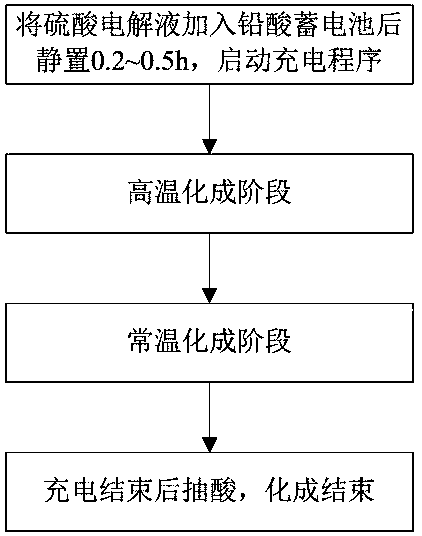

[0035] Embodiment: a kind of power type lead-acid storage battery high temperature internalization method of the present embodiment, such as figure 1 shown, including the following steps:

[0036] S1: Add the sulfuric acid electrolyte to the lead-acid battery and let it stand for 0.2~0.5h, then start the charging procedure;

[0037] S2: High-temperature formation stage (no cooling water is added to the battery tank during the process), including the following steps:

[0038] S201: Charge with a constant current of 0.1~0.2I2 for 1~2 hours;

[0039] S202: Charge with a constant current of 0.3~0.5I2 for 3~4 hours;

[0040] S203: Charge with a constant current of 0.5~0.6I2 for 5~8 hours;

[0041] S3: normal temperature formation stage, including the following steps:

[0042] S301: Stand still for 0.5h after high-temperature charging;

[0043] S302: Charge with a constant current of 0.4~0.5I2 for 10~14 hours, and then stand still for 0.5 hours;

[0044] S303: Charge with a co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com