Combined plate pressing process of inner-layer thin core plate and multi-layer prepregs

A technology of prepreg and inner core board, applied in multilayer circuit manufacturing, electrical components, printed circuit manufacturing, etc. The performance cannot meet the needs of product design, etc., to achieve the effect of high electrical performance and mechanical performance, and ensure the uniformity of plate thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The pressing board is a process that uses high temperature and high pressure to cure the prepreg (pp) by heat, and then bond one or more inner layer etched core boards and copper foils into a multi-layer board. It is a means of the whole, but when 6 layers of prepregs are placed between the inner core boards for lamination, during the lamination process, due to the large flow of glue of the 6 layers of prepregs, partial layer deviation will occur due to the pulling of the flow glue, Expansion and shrinkage lead to poor thickness uniformity of the final multilayer board, difficulty in accurately controlling the thickness, and poor electrical and mechanical properties of the obtained multilayer board.

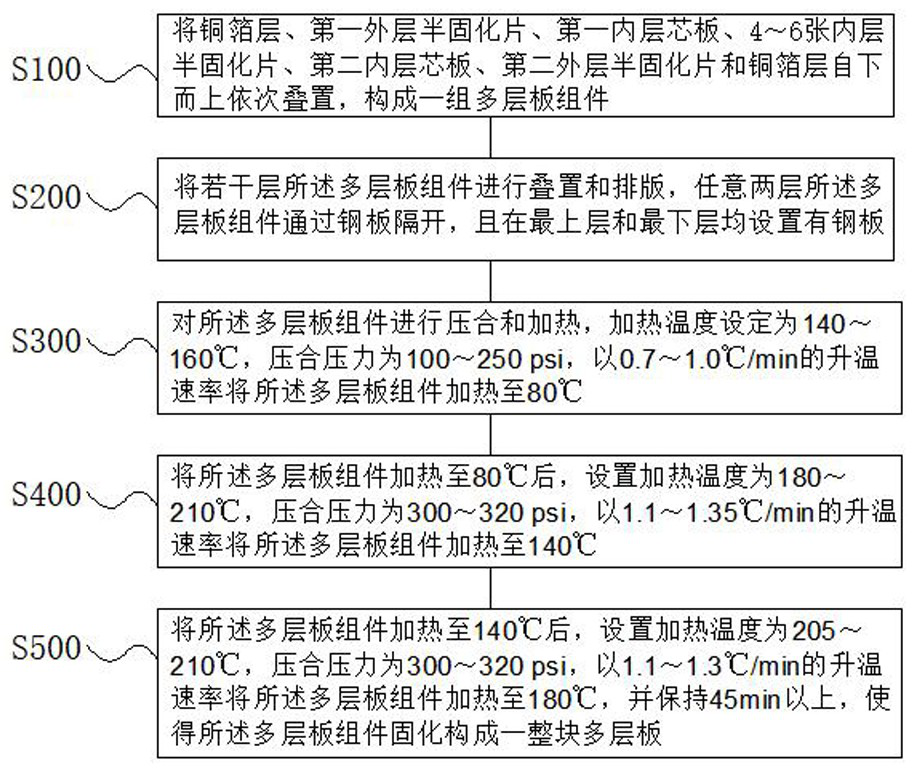

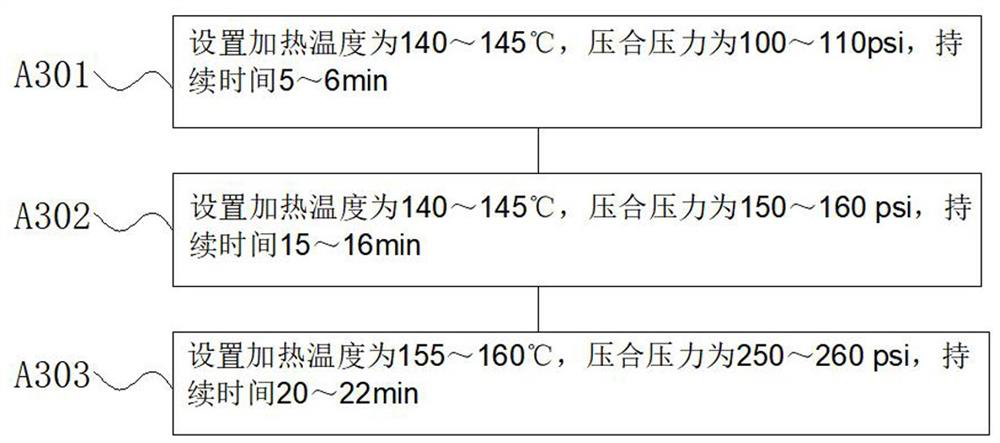

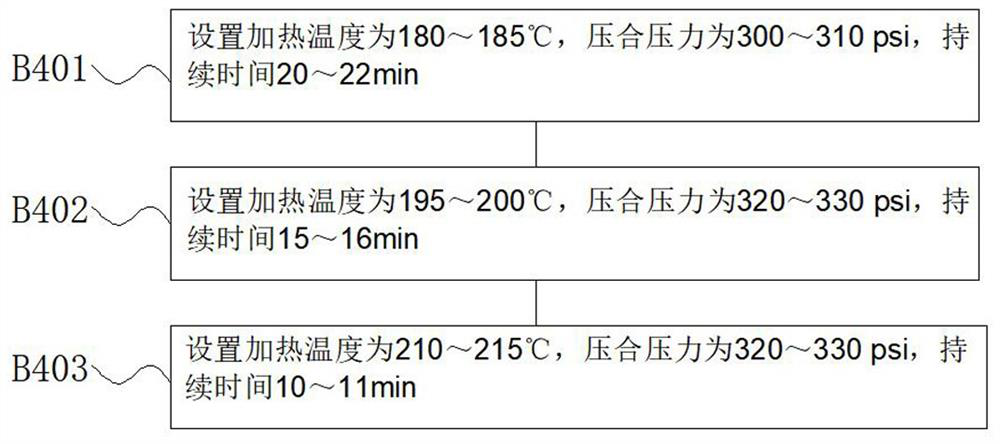

[0034] In order to solve the above technical problems, this embodiment provides a combined pressing process of the inner thin core board and multi-layer prepreg, such as figure 1 shown, including the following steps:

[0035] S100, stack the copper foil layer, the first o...

Embodiment 2

[0062] Referring to Embodiment 1, when laminating and heating the multilayer board assembly, in steps S300-S500, this embodiment provides another set of process parameters for pressure, heating temperature, and heating time, as shown in Table 4 .

[0063]

[0064] Compared with Example 1, the heating temperature and pressure parameters of each step are roughly the same, the difference is the duration of each step, the temperature at which the prepreg turns into a glass state is 150°C, and the temperature from 80°C to 180°C will affect the transformation of the prepreg into glass The speed of the state can be calculated from the parameter table in Table 4. Through the pressing process carried out by this set of parameters, the heating rate of the middle layer multilayer board assembly is 1.68°C / min from 80°C to 175°C, and the outer layer multilayer board assembly is 1.68°C / min. The temperature rise rate of the component is 1.47°C / min, which is relatively fast compared with E...

Embodiment 3

[0066] Referring to Example 1, when laminating and heating the multilayer board assembly, in steps S300-S500, this example provides another set of process parameters for pressure, heating temperature, and heating time, as shown in Table 5 .

[0067]

[0068] Compared with Example 1, the high pressure in step S400 is reduced, the heating temperature is similar, and the time is shortened. The temperature at which the prepreg turns into a glass state is 150°C, and the temperature from 80°C to 180°C will affect the rate at which the prepreg turns into a glass state, as shown in the table It can be calculated from the parameter table of 5 that the pressing process carried out by this set of parameters, the heating rate of the middle layer multilayer board assembly is 1.42°C / min from 80°C to 175°C, and the heating rate of the outer layer multilayer board assembly is 1.37°C / min, compared with Example 1, the heating rate is faster, and the pressure and heating temperature affect th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com