Patents

Literature

31results about How to "Avoid expansion and contraction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for once molding inner-layer line of multilayer flexible circuit board

ActiveCN103079365AImprove qualityAvoid expansion and contractionMultilayer circuit manufactureMicroetchingProduction rate

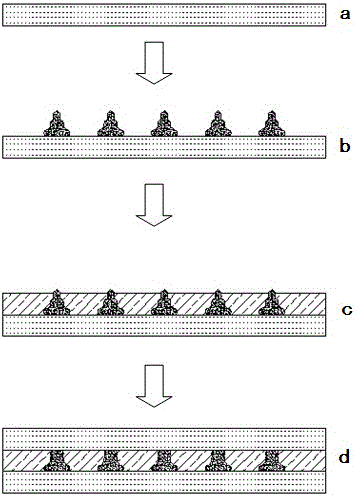

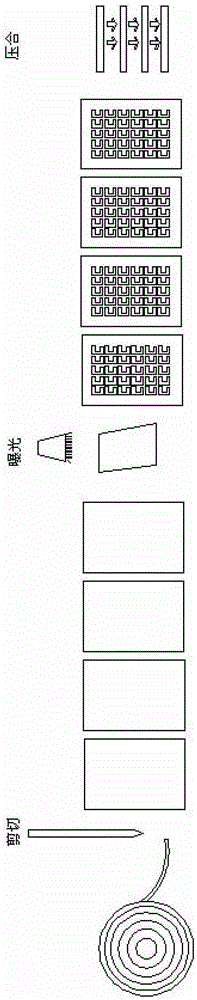

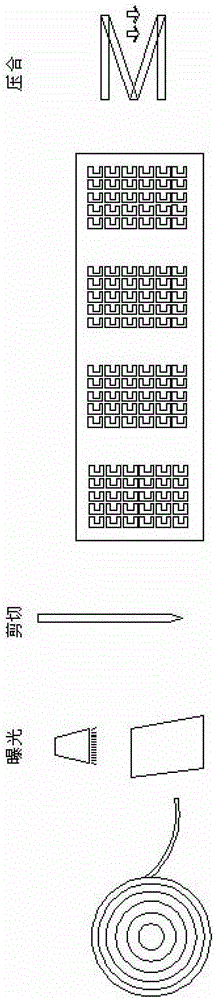

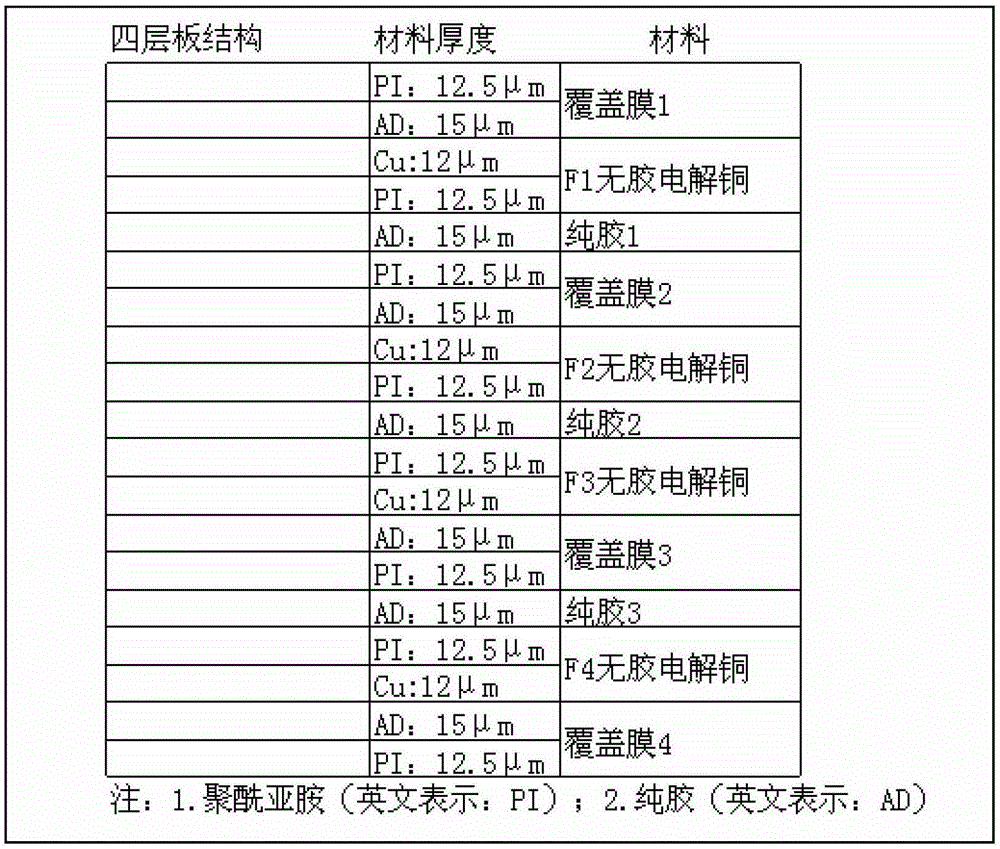

The invention discloses a method for once molding an inner-layer line of a multilayer flexible circuit board, and technical problems to be solved are improving the production efficiency and the qualified rate of products. The method for once molding the inner-layer line of the multilayer flexible circuit board comprises the following steps of: pasting a dry film in a whole roll, manufacturing an inner-layer line board of a multilayer board of a flexible circuit board, manufacturing an inner-layer line-board layer, manufacturing an inner-layer line-board combined layer, and manufacturing the inner-layer line of the multilayer flexible circuit board. Compared with the prior art, the processing flows of dry-film pasting, exposing, developing, etching, film removing, microetching and pressing are adopted by the invention to manufacture the inner-layer line board, the inner-layer line-board layer, the inner-layer line-board combined layer and the multilayer flexible circuit board, so that problems of height drop generated between a glued area and a non-glue area after inner-layer soft boards are pressed and expansion and shrinkage of the soft boards caused by pressing an inner-layer covering film for many times are avoided, the quality of the multilayer flexible circuit board is improved, the qualified rate reaches more than 92 percent, the process flow is shortened, and the production rate is improved.

Owner:SHENZHEN XINYU TENGYUE ELECTRONICS

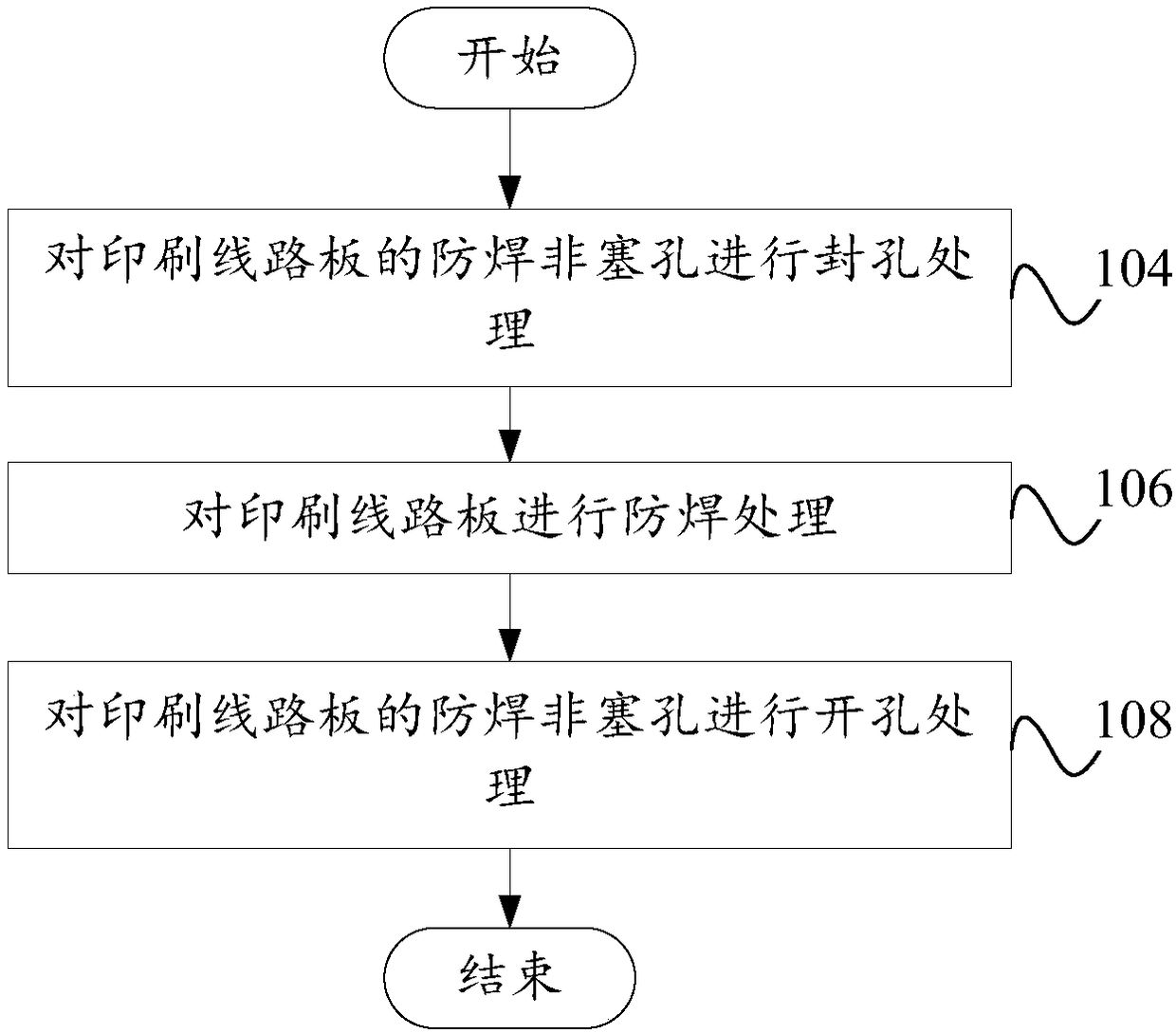

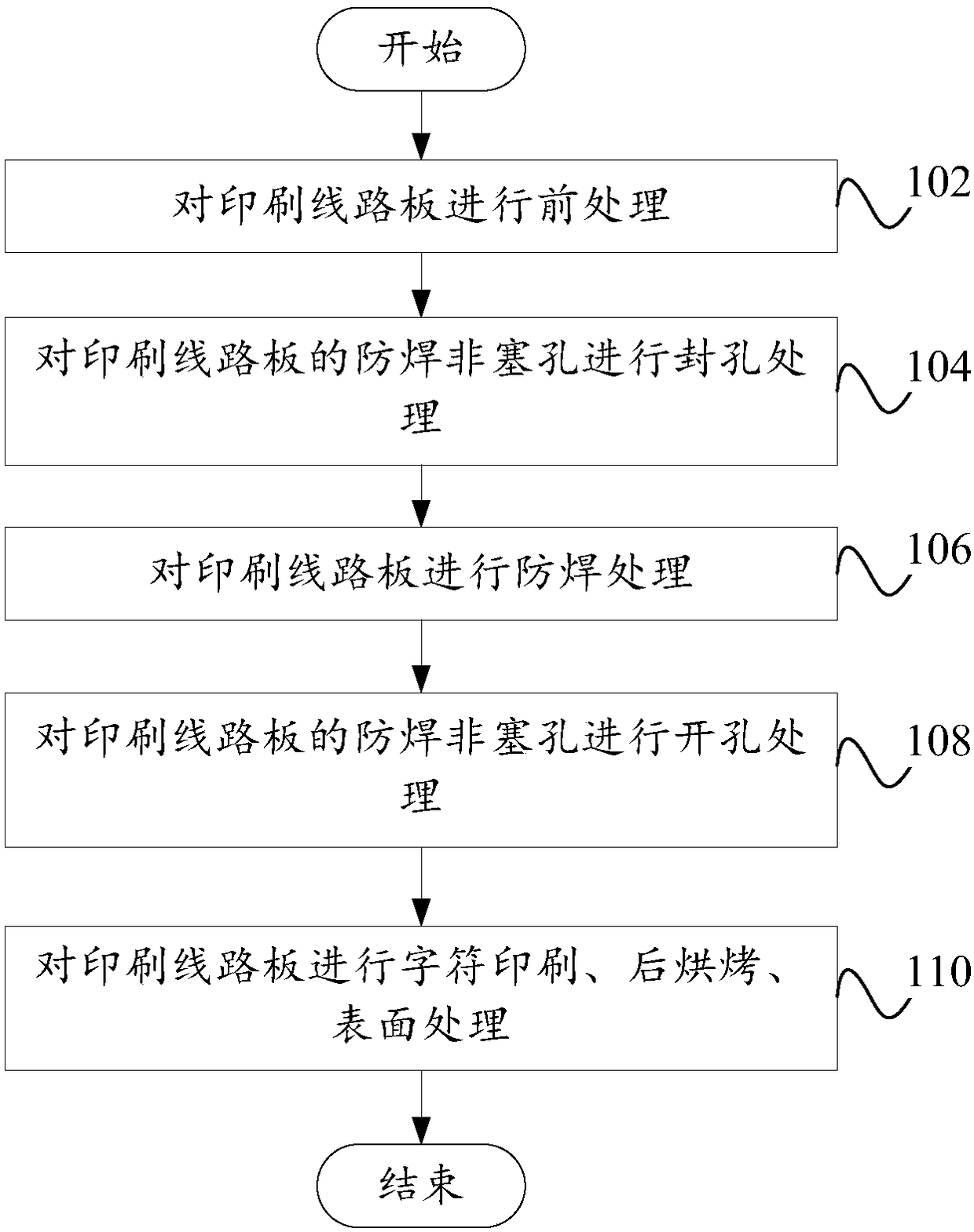

Method for preventing solder mask ink from plugging hole, printed circuit board and computer device

InactiveCN108934128AAvoid incomplete ink printingAvoid pluggingNon-metallic protective coating applicationSolder maskEngineering

The invention provides a method for preventing solder mask ink from plugging a hole, a printed circuit board, a computer device and a computer readable storage medium. The method for preventing the solder mask ink from plugging the hole comprises the following steps: a solder mask non-plugging hole of the printed circuit board is subjected to hole sealing operation; solder masking operation is performed on the printed circuit board; the solder mask non-plugging hole of the printed circuit board is subjected to hole opening operation. The method disclosed in the present invention can help prevent the non-plugging hole from being plugged by ink, the method can help prevent a problem of printed circuit board and blocking point net expansion and shrinkage that occurs when block point net ink is used and a problem of alignment precision, scrapping of the printed circuit board which is caused when the hole is plugged by ink can be reduced, and high reliability and high efficiency can be realized.

Owner:PEKING UNIV FOUNDER GRP CO LTD +1

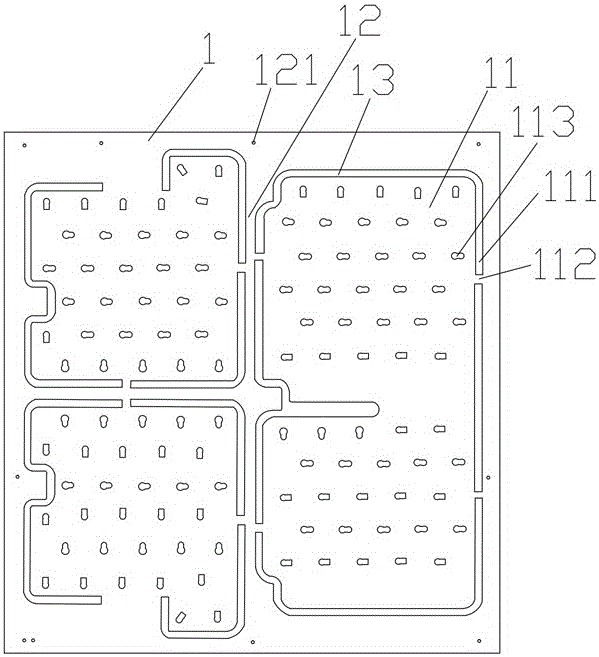

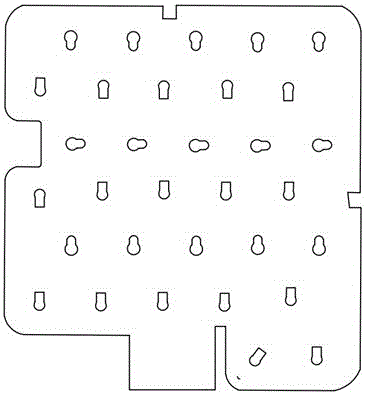

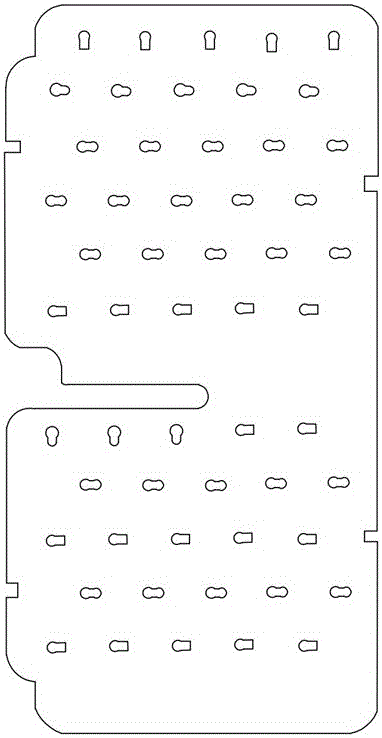

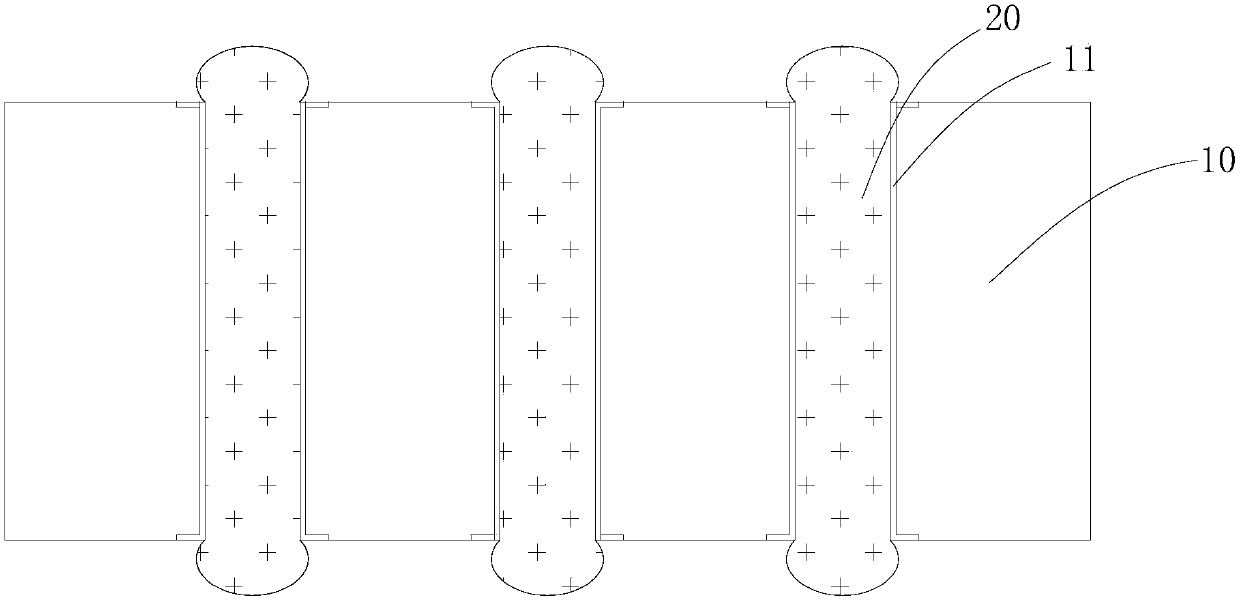

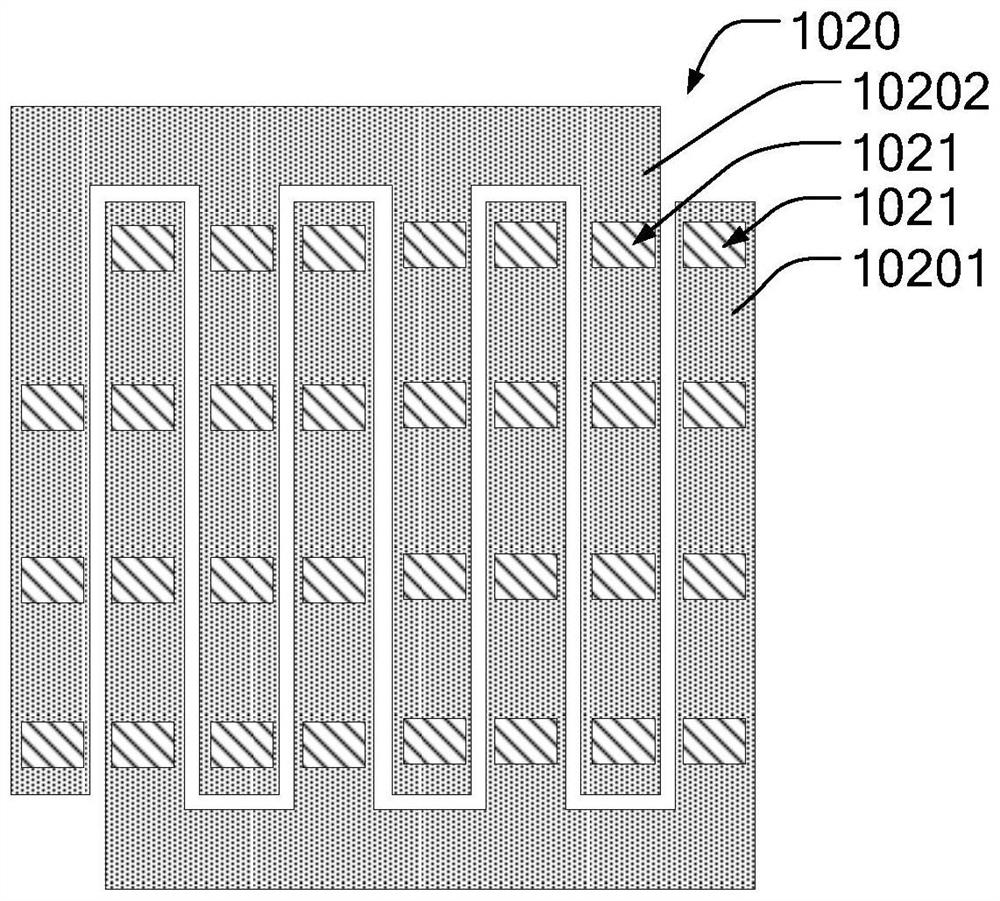

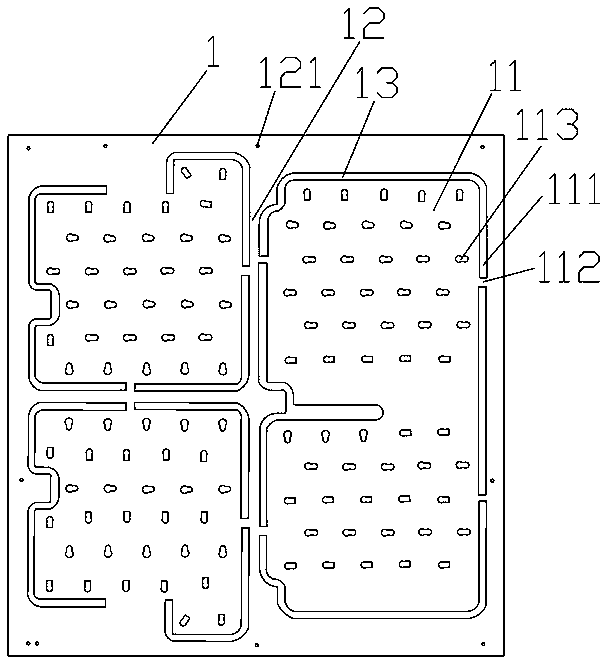

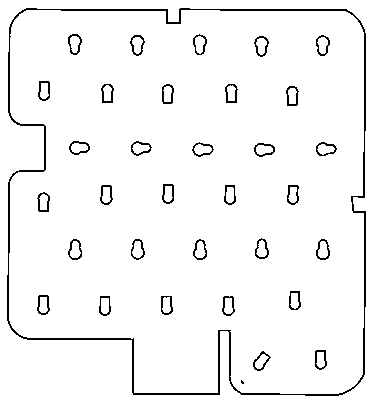

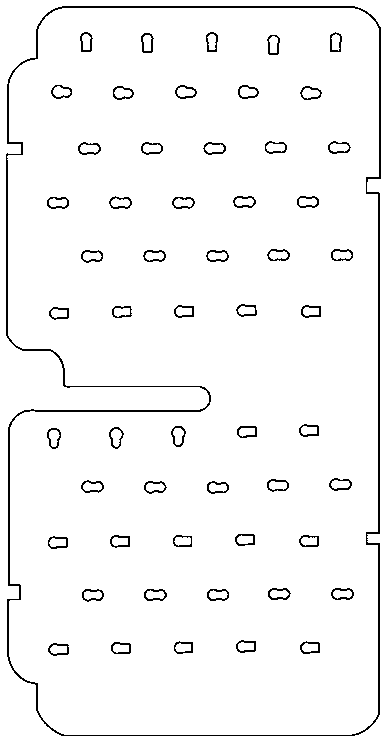

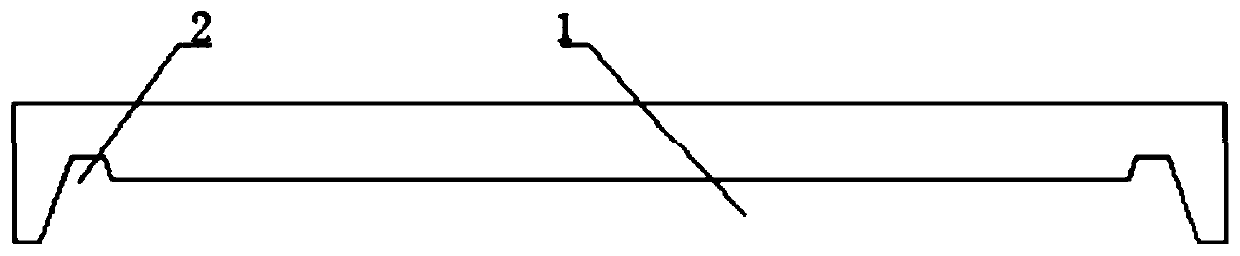

Thick copper plate for different types of circuit boards and production method for circuit board

ActiveCN105704914AIncrease profitReduce manufacturing costMultilayer circuit manufactureCircuit laminationBatch productionEngineering

The invention discloses a thick copper plate for different types of circuit boards and a production method for the circuit board. The thick copper plate is of a square structure, and a thick copper plate unit and a connecting area are arranged on the thick copper plate; a gong side and a connecting position are arranged at the outer side of each thick copper plate unit, and each thick copper plate unit is connected to a connecting part through the connecting position; a plurality of locating holes are arranged in the connecting area and are located on a frame of the thick copper plate. The invention also discloses a production method for the circuit board. According to the thick copper plate for different types of circuit boards and the production method for the circuit board, the utilization rate of the board and the production efficiency of the circuit board are effectively improved, the production cost is saved, the waste of the production raw materials is reduced and the fast batch production is realized; meanwhile, the circuit board is directly formed in the thick copper plate and then composing and laminating are carried out without taking an FR4 substrate as a lag, so that the expansion problem of materials of the copper plate and the FR4 substrate after laminating is avoided, the use of the FR4 substrate is reduced, the production process and the production time are reduced, an effect of coating the FR4 substrate on the copper plate is better realized, and the circuit board is protected.

Owner:南通胜宏科技有限公司

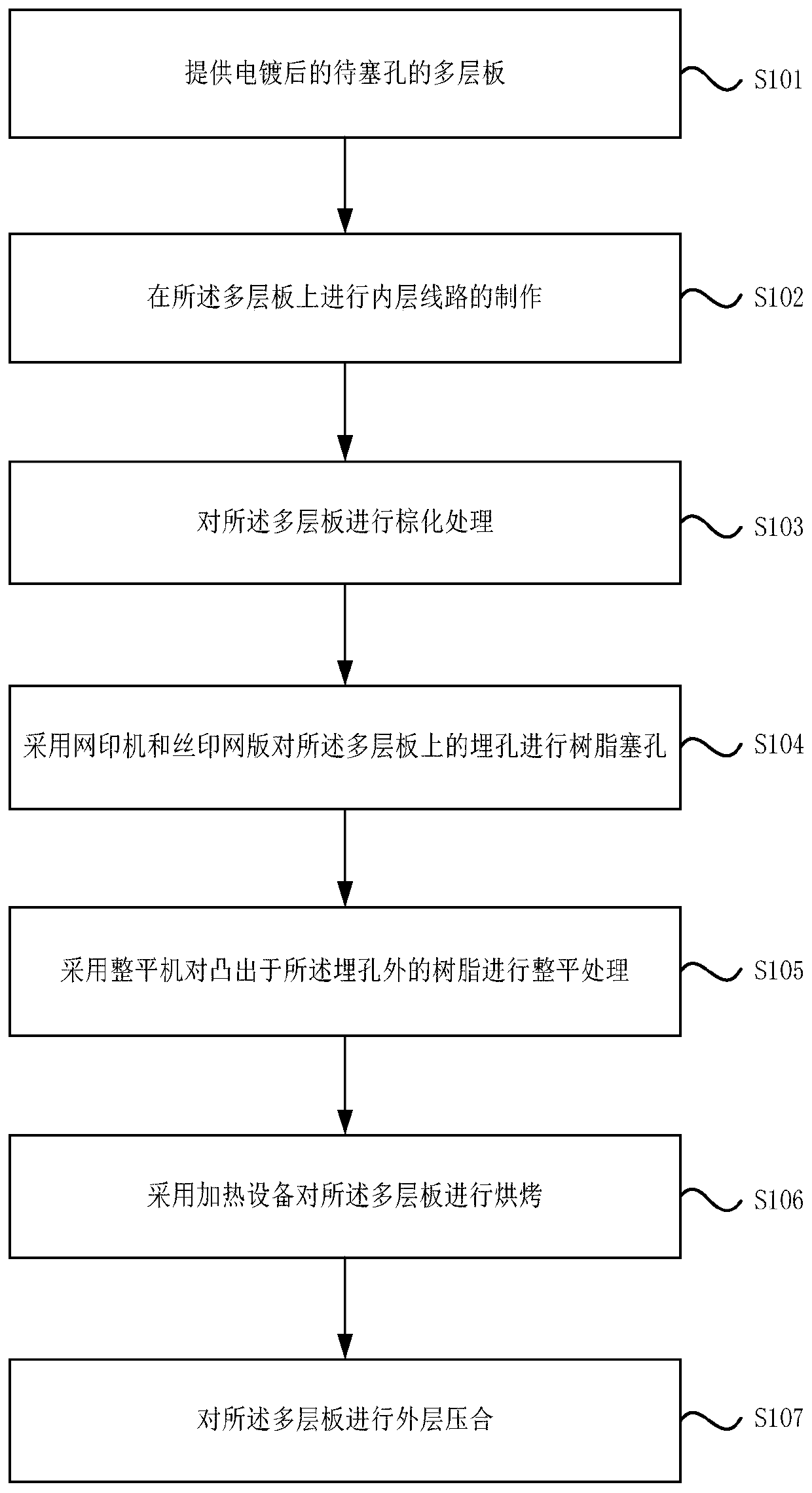

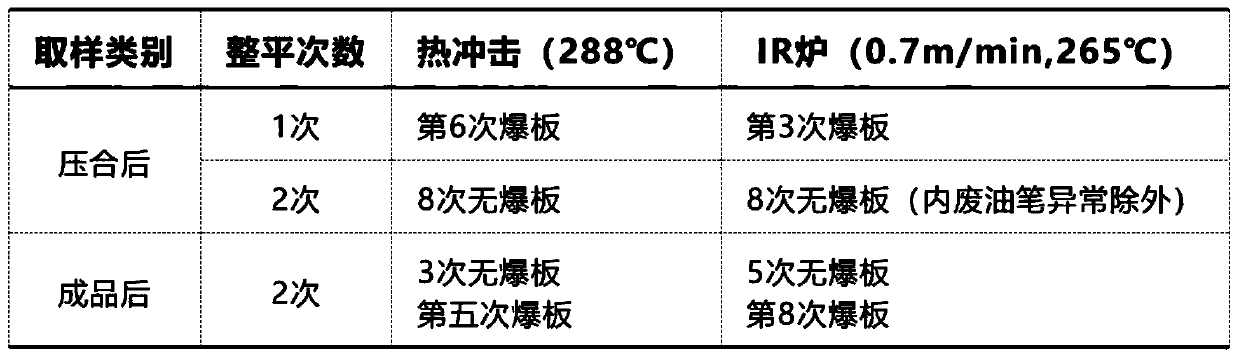

Circuit board buried hole resin hole plugging method

PendingCN111093330AAvoid troubleAvoid expansion and contractionMultilayer circuit manufactureScreen printingThin slab

The invention discloses a circuit board buried hole resin hole plugging method. The method comprises the following steps of: providing an electroboardd multilayer board to be subjected to hole plugging, manufacturing an inner layer circuit on the multilayer board, carrying out browning treatment on the multilayer board, performing resin hole plugging on the buried holes in the multilayer board byadopting a screen printer and a screen printing board, conducting leveling treatment on the resin protruding out of the buried hole through a leveling machine, baking the multilayer board by adoptingheating equipment, and laminating the outer layer of the multilayer board. According to the circuit board buried hole resin hole plugging method provided by the invention, through the process technology of resin hole plugging after browning, the trouble of thin board resin board grinding in the prior art is solved, the expansion and shrinkage problems caused by thin board resin hole plugging boardgrinding are avoided, on the other hand, the board explosion problem caused by thin PP pressing glue filling shortage is solved, and good reliability of products is guaranteed.

Owner:东莞市五株电子科技有限公司

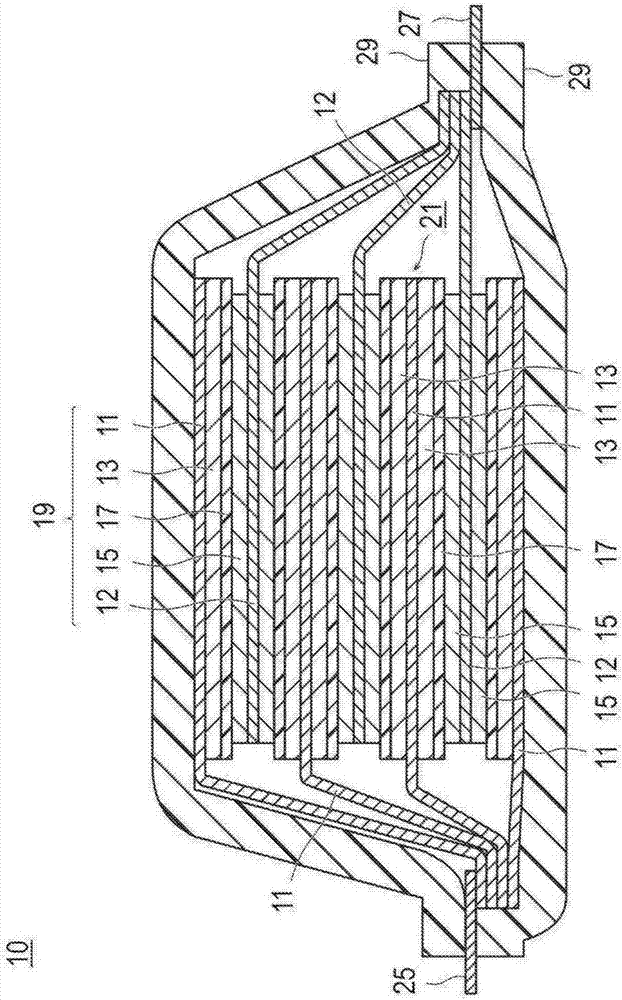

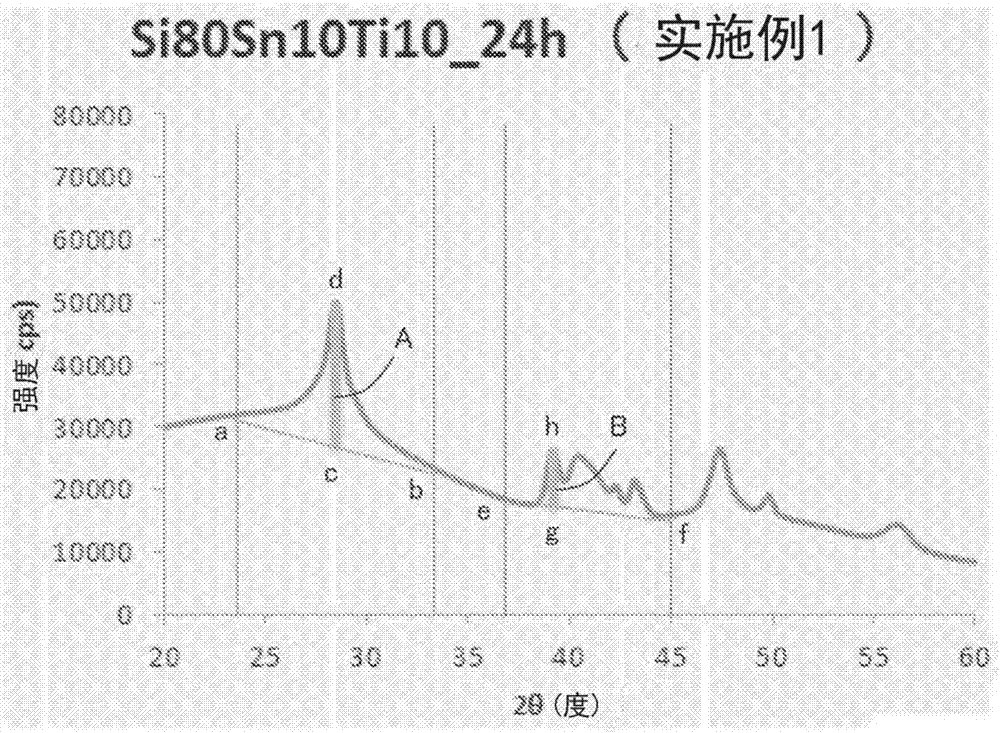

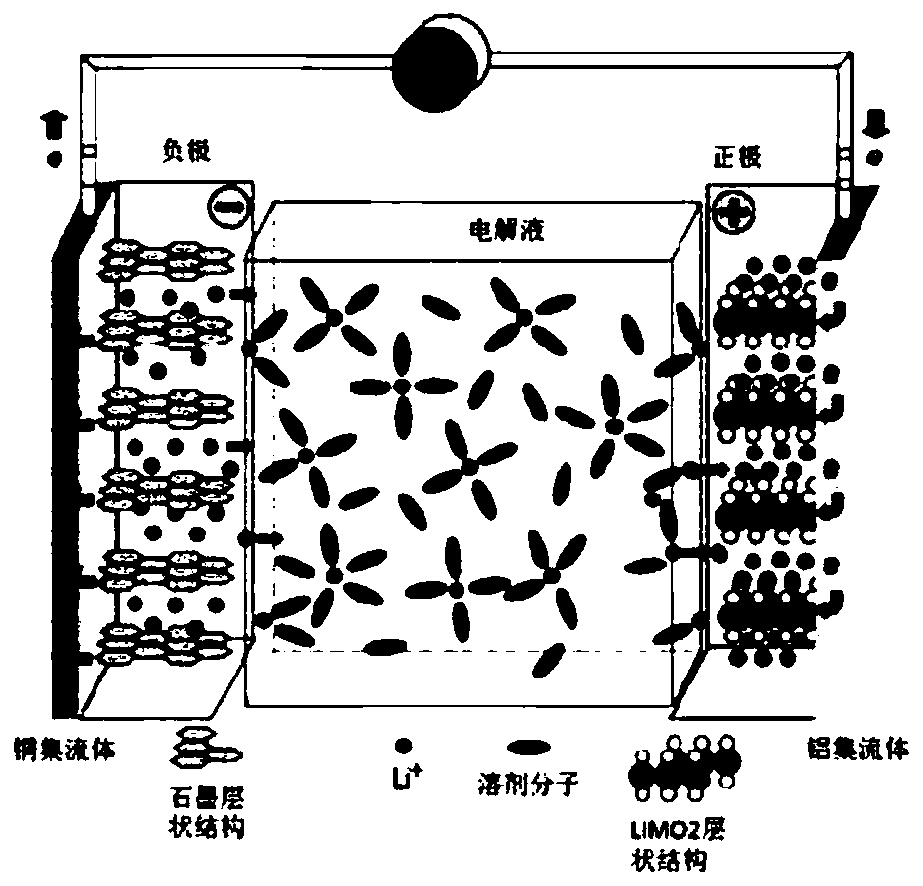

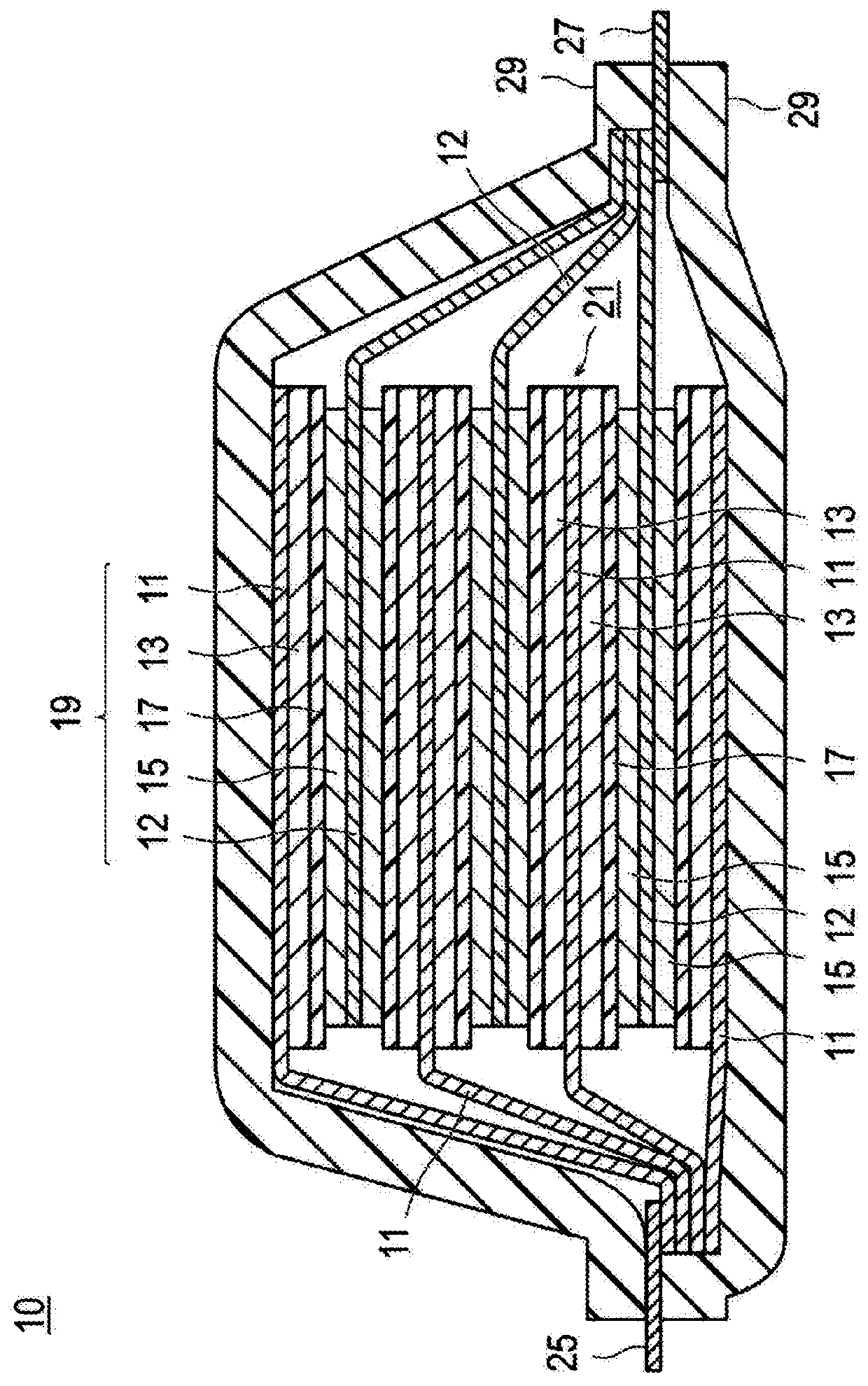

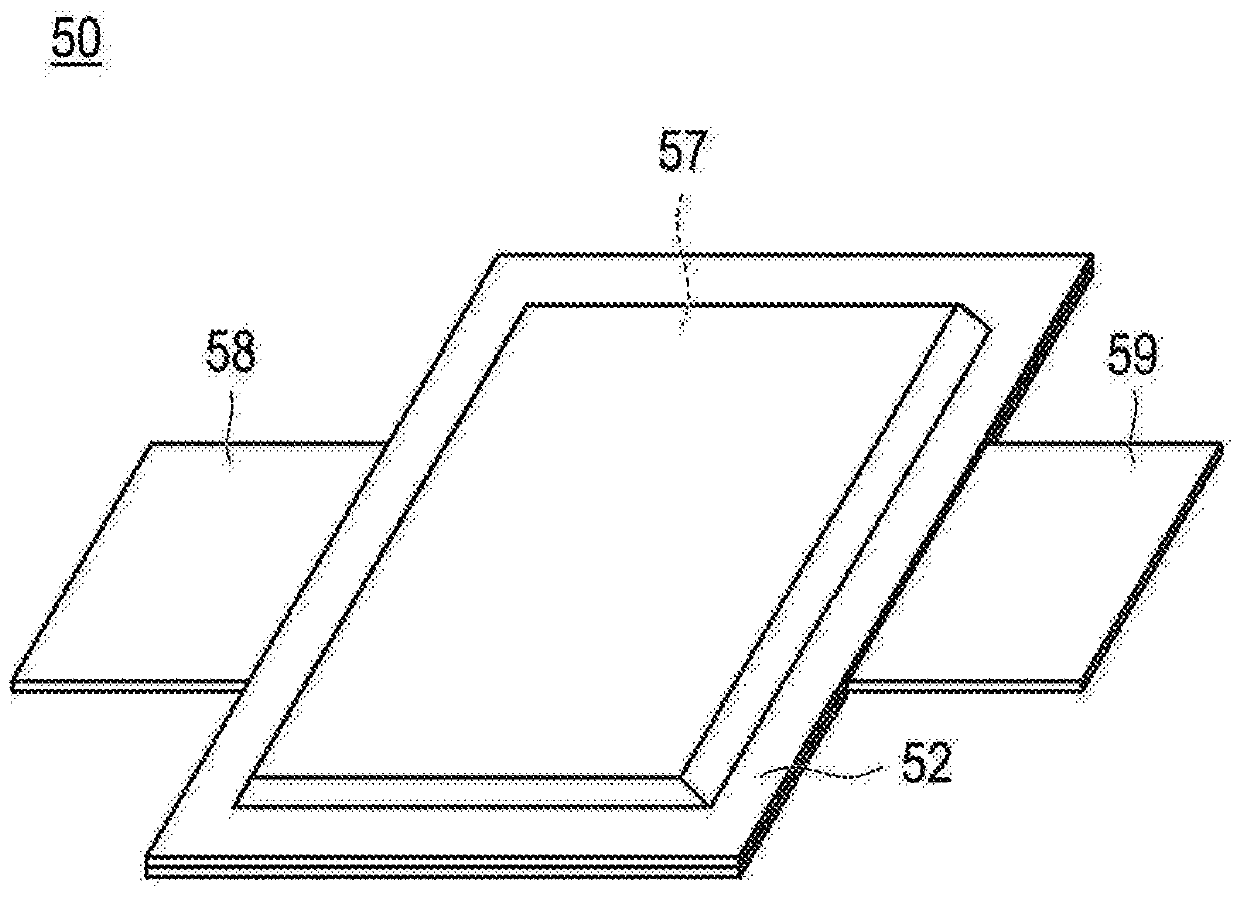

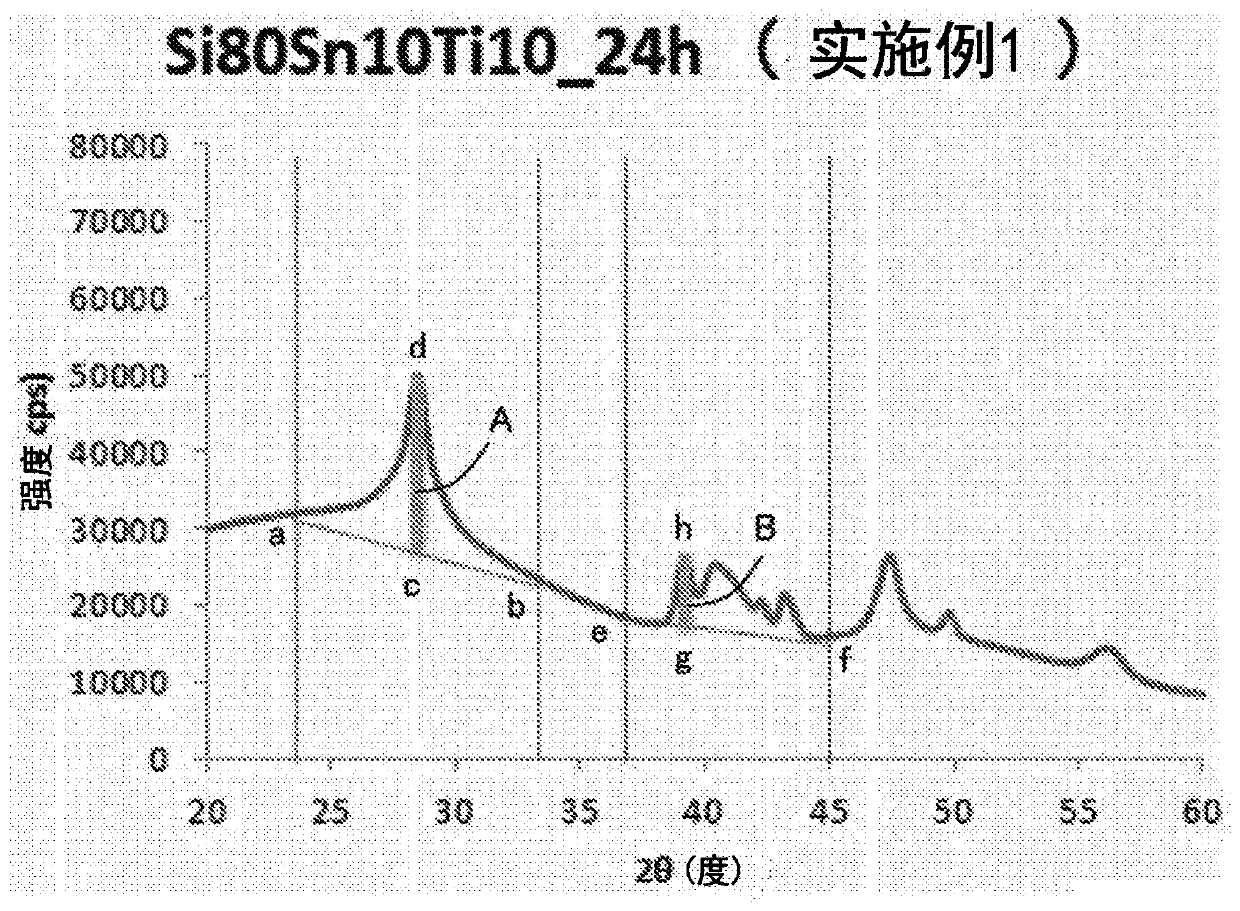

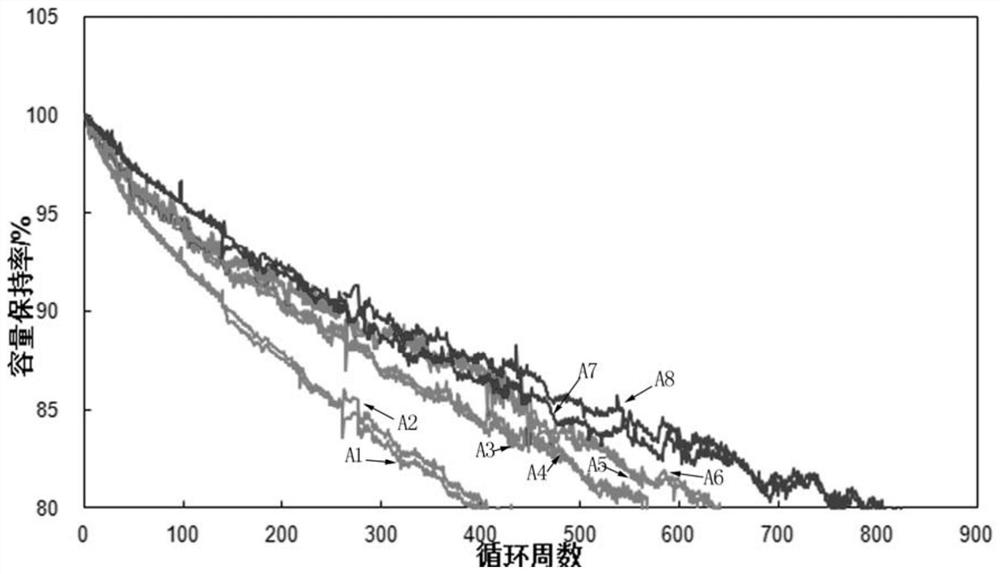

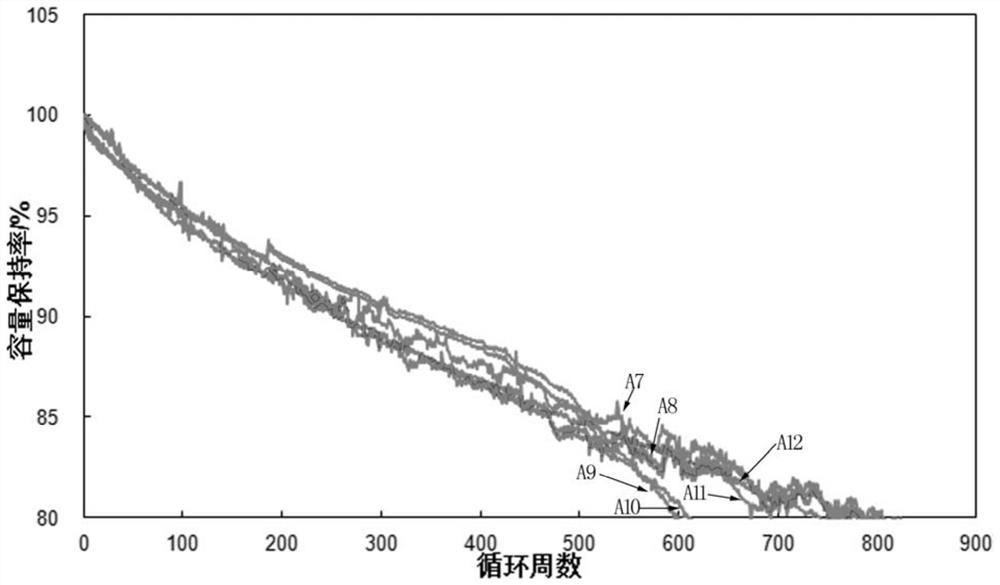

Negative-electrode active material for electrical device, and electrical device using same

ActiveCN107112518AAvoid expansion and contractionHigh cycle durabilityNegative electrodesLi-accumulatorsX-rayElectrical devices

The invention provides a means capable of improving the cycle durability of an electrical device such as a lithium-ion secondary battery. [Solution] Using, for an electrical device, a negative-electrode active material made of a silicon-containing alloy that has a predetermined composition and has a structure in which silicide phases including a silicide of a transition metal are dispersed in a matrix phase including amorphous or low-crystalline silicon as a main component, wherein, in an X-ray diffraction measurement of said silicon-containing alloy using a CuKalpha1 beam, the value of the ratio (B / A) of the diffraction peak intensity B of the transition metal silicide in the range 2 [theta] = 37 to 45 degrees to the diffraction peak intensity A of the (111) plane of Si in the range 2 [theta] = 24 to 33 degrees is 0.41 or greater.

Owner:NISSAN MOTOR CO LTD

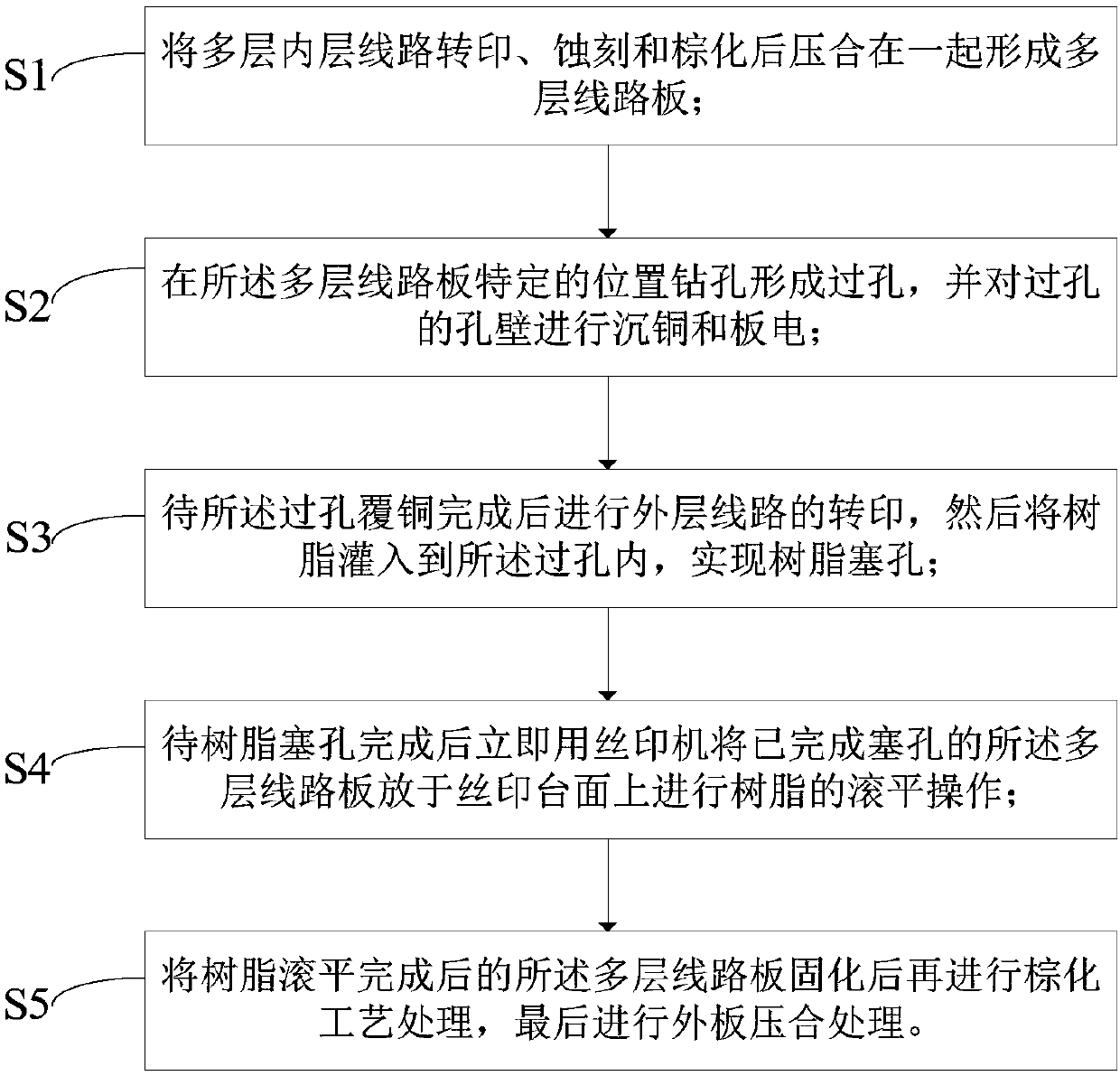

Manufacturing method of hole buried circuit board

InactiveCN107835590AAvoid expansion and contractionAvoid board warpingMultilayer circuit manufacturePrinted element electric connection formationEngineeringCopper

The invention provides a manufacturing method of a hole buried circuit board, and belongs to the technical field of printed circuit boards. Multiple internal lines are transferred, etched and brownedand then laminated to form a multilayer circuit board; the multilayer circuit board is bored in specific positions to form through holes, and coppering and electroplating are carried out on the wallsof the through holes; an external line is transferred after that the through holes are coppered, and resin is filled into the through holes so that resin is plugged into the holes ; after that the holes are plugged with resin, a silkscreen machine places a multilayer circuit board whose holes are plugged on a silkscreen table top to roll the resin; and after that the resin is rolled, the multilayer circuit board is solidified and browned, and the external board is pressed. Thus, the quality problems that the circuit board expands and contracts, the board surface is warped and base materials are exposed due to the fact that spilt glue needs to be peeled in the present manufacturing process of the hole buried circuit board can be solved.

Owner:SHENZHEN KINWONG ELECTRONICS

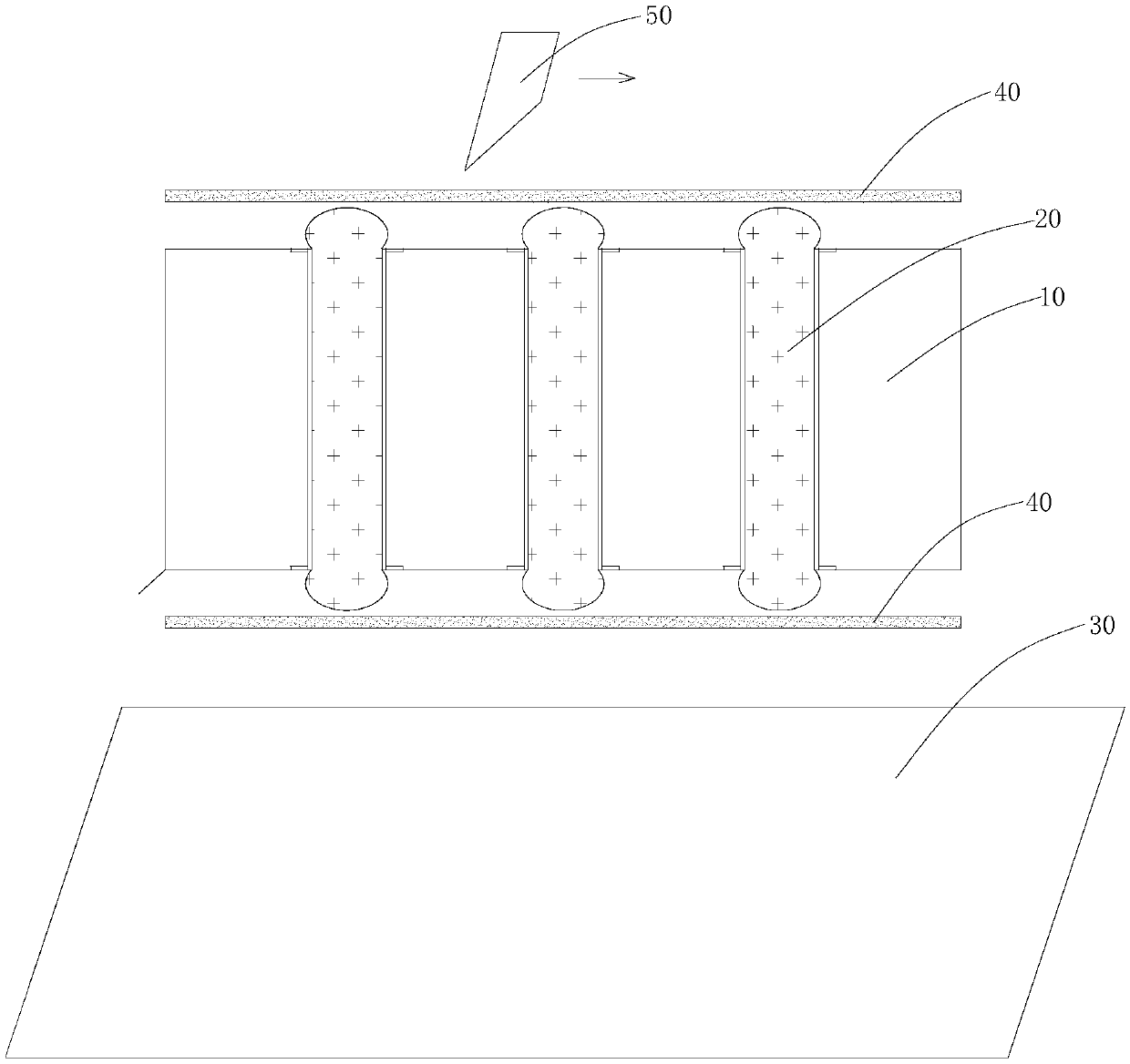

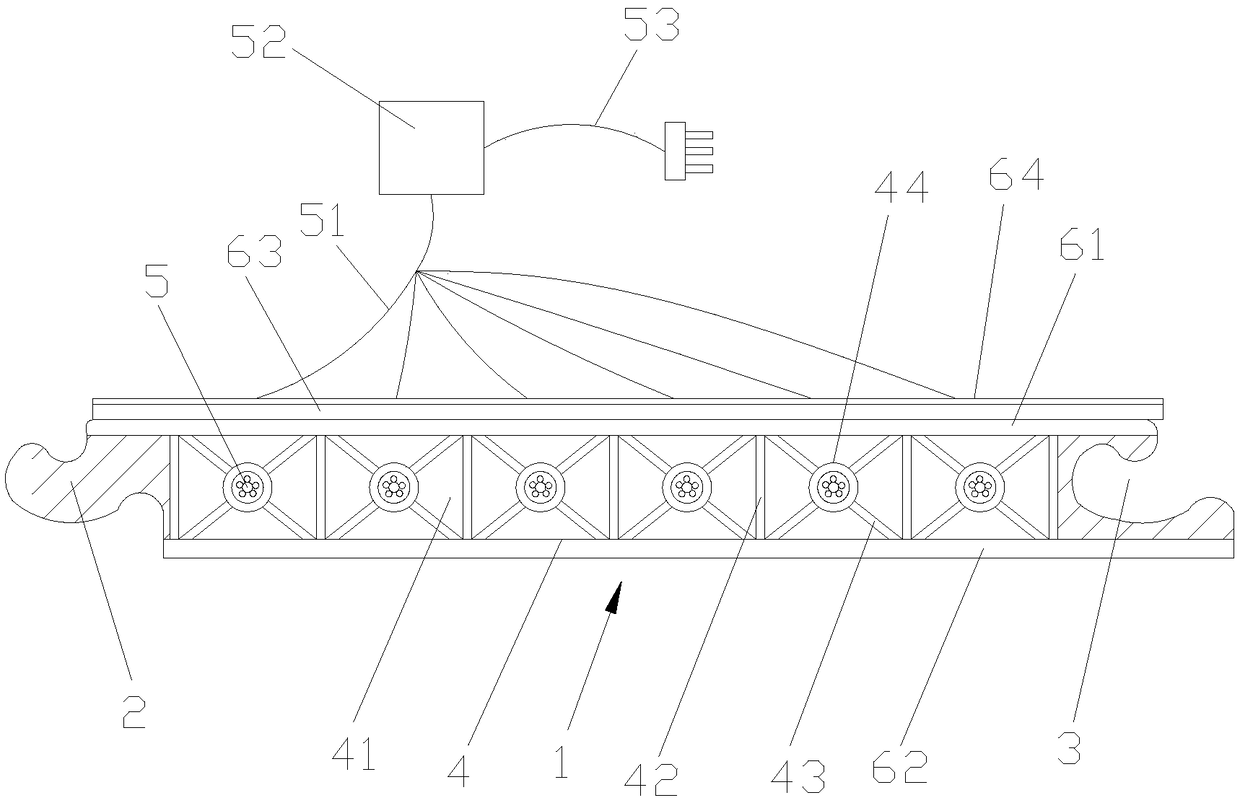

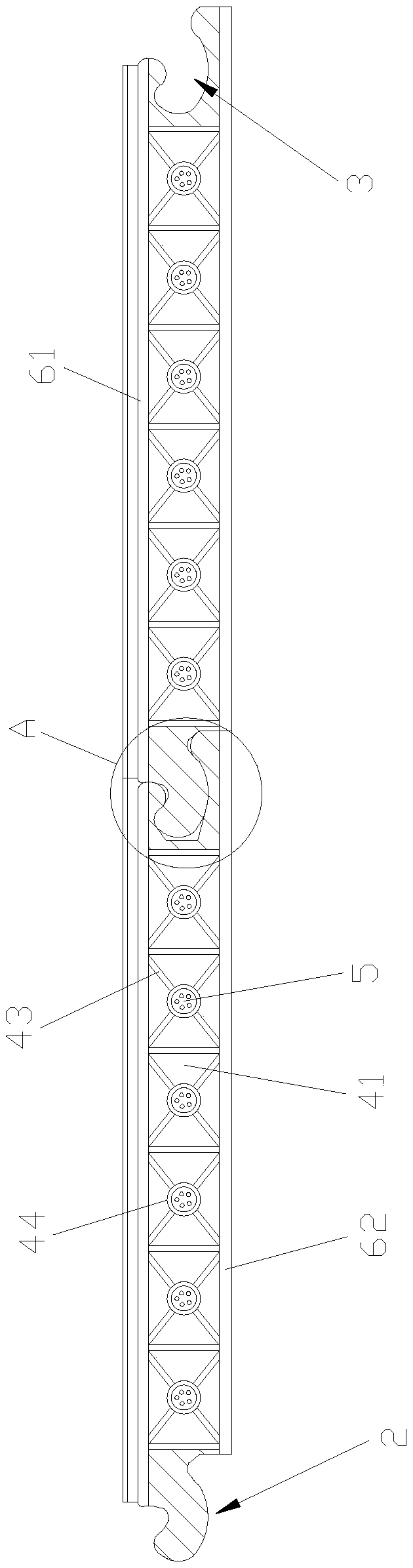

Electrically heated wooden floor

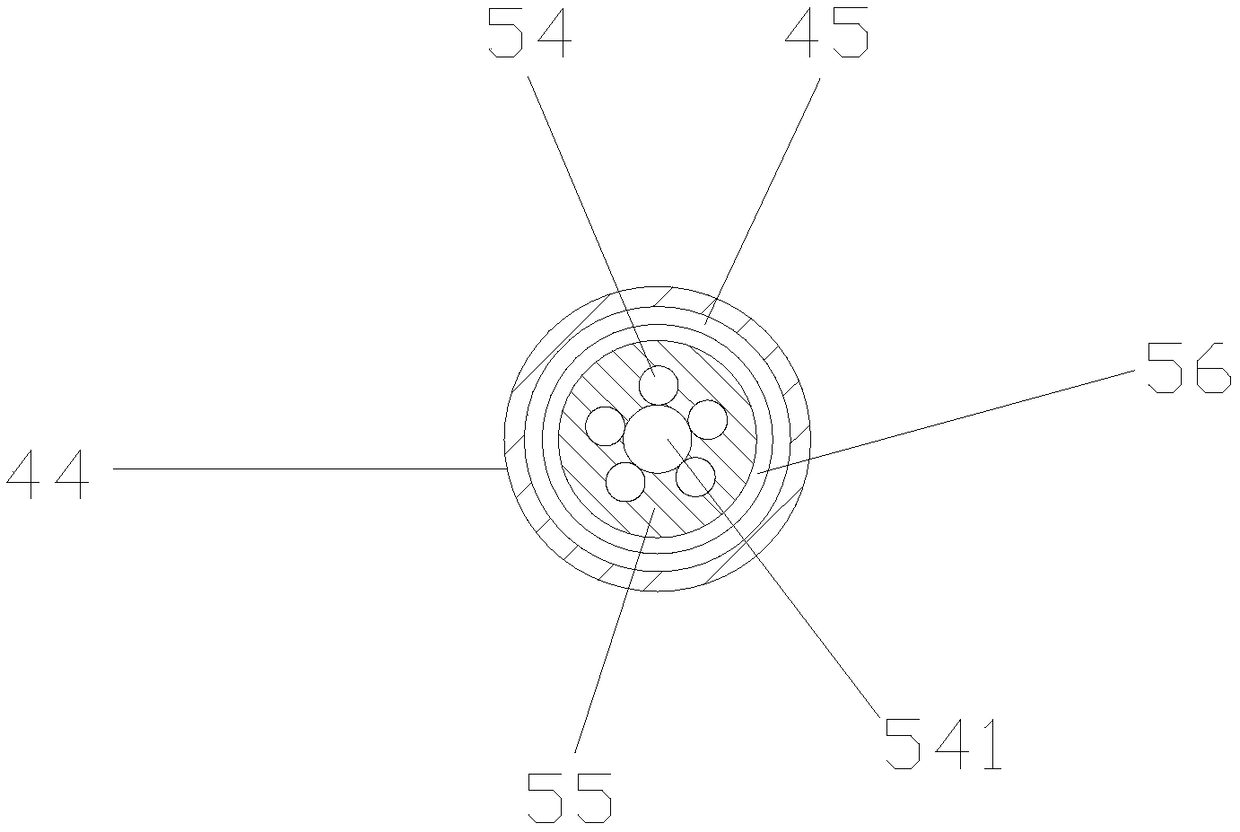

InactiveCN108894459AAdjust the temperature freelyComfortable temperatureLighting and heating apparatusElectric heating systemFiberCarbon fibers

An electrically heated wooden floor, include a floor body, the two ends of the floor main body are respectively provided with matching tongue and tongue groove, a heating layer is arranged inside thefloor body, The heating layer is provided with a hollow groove, a plurality of vertical isolation ribs are arranged in the hollow groove, reinforcing ribs are arranged crosswise between adjacent isolation ribs, a threading pipe is arranged at the crosswise part of the reinforcing ribs, a carbon fiber heating wire is arranged in the threading pipe, the carbon fiber heating wire is centrally connected with an external temperature controller through a cold lead, and a power supply wire is connected on the temperature controller. The invention has the characteristics of good heating effect, convenient installation, maintenance and good comfort.

Owner:湖州春阁家居科技有限公司

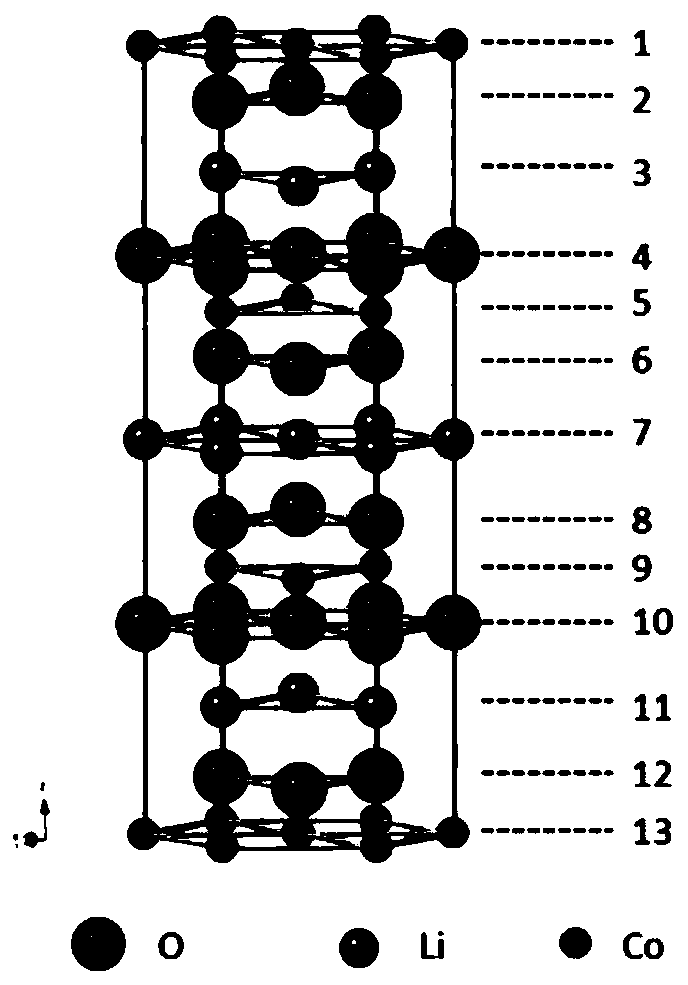

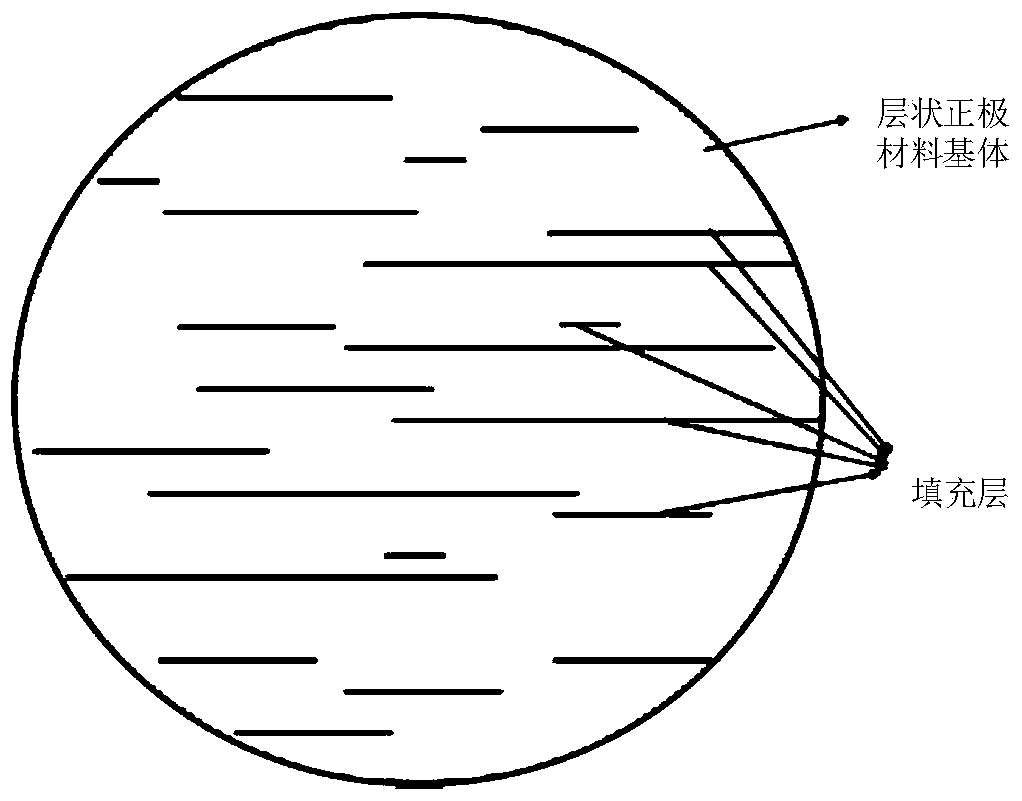

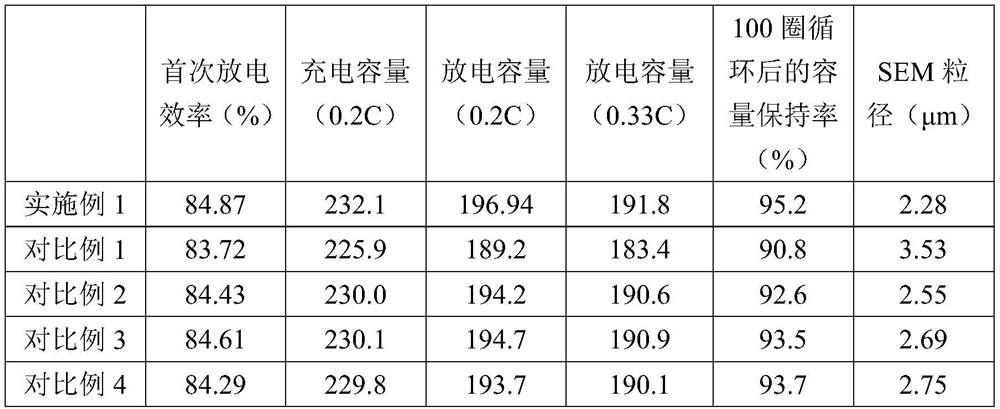

Lithium ion battery positive electrode material and preparation method

ActiveCN111129450AAvoid expansion and contractionSuppressed dislocationElectrode thermal treatmentPositive electrodesLithium-ion batteryBattery cell

The invention provides a lithium ion battery positive electrode material and a preparation method thereof. The lithium ion battery positive electrode material comprises a layered positive electrode material matrix and a filling layer, the layered positive electrode material matrix comprises main body plate layers and a lithium layer, the filling layer comprises a first element or a second element,and the content of the first element or the second element in the filling layer is higher than the content of the first element or the second element in the layered positive electrode material matrix; and the first element or the second element in the filling layer is arranged in a gap between the main body plate layers, or ions formed by the first element in the filling layer replace cations ofthe layered positive electrode material matrix, or ions formed by the second element in the filling layer replace anions of the layered positive electrode material matrix. In the charging and discharging process, the volume of the filling layer in the positive electrode material of a lithium ion battery does not change along with the volume of the layered positive electrode material matrix, so that the positive electrode material structure of the lithium ion battery is stabilized.

Owner:HUAWEI TECH CO LTD +1

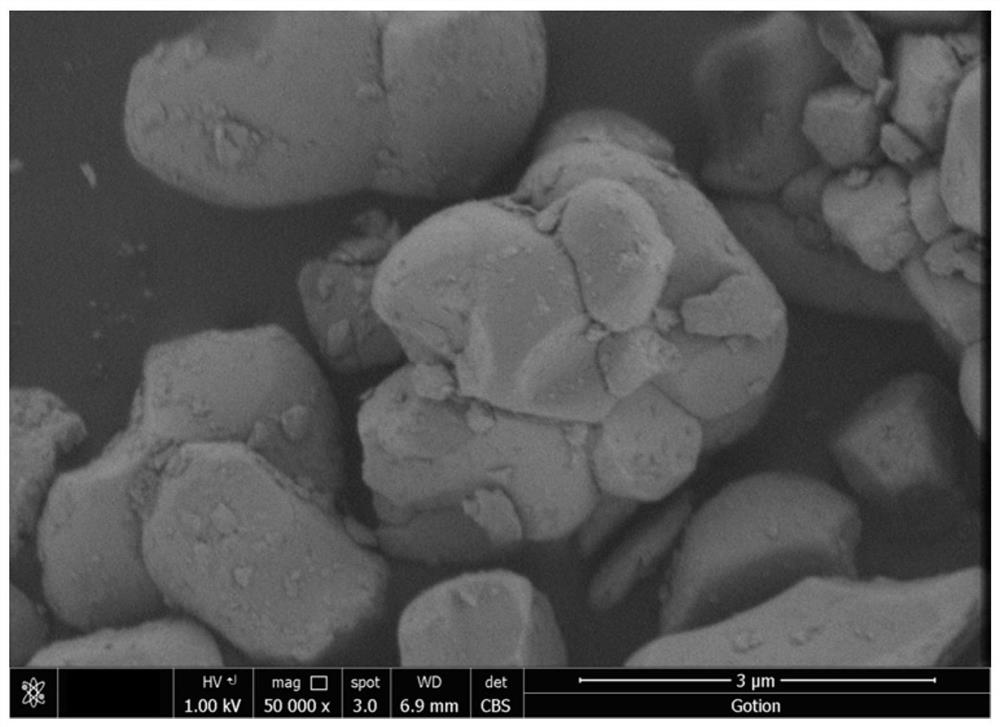

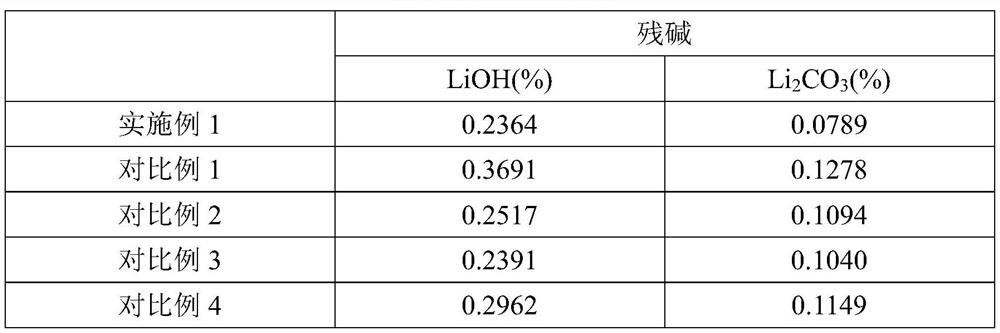

Positive electrode material and preparation method thereof, lithium ion battery positive electrode and lithium ion battery

InactiveCN113540433AImprove cycle stabilitySmall particle sizeElectrode thermal treatmentSecondary cellsElectrical batteryPhysical chemistry

The invention discloses a positive electrode material and a preparation method thereof, a lithium ion battery positive electrode and a lithium ion battery, the positive electrode material comprises nickel cobalt lithium manganate doped with Zr element and a coating layer formed on the surface of the nickel cobalt lithium manganate, wherein the coating layer is composed of H3BO3 and Al2O3. The obtained positive electrode material is small in particle size and compact in coating layer, and can effectively improve the electrochemical stability and cycle performance of the lithium ion battery, reduce residual alkali, reduce flatulence and improve the comprehensive performance of the lithium ion battery.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

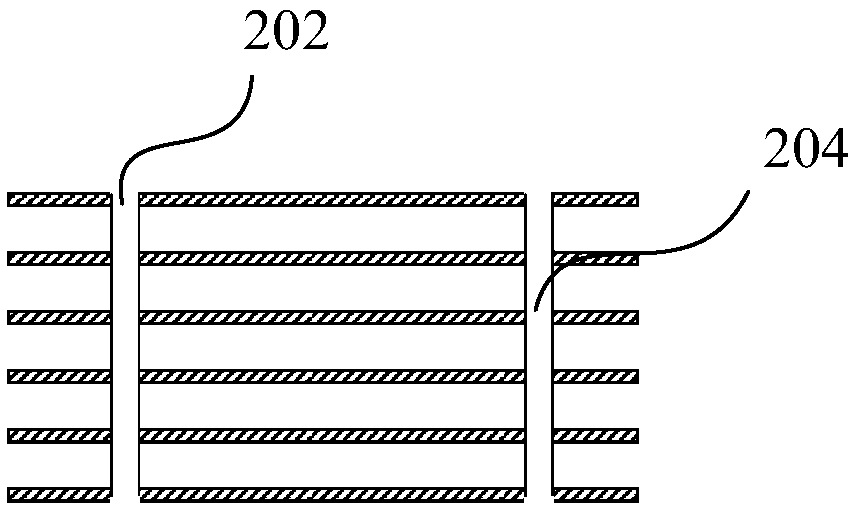

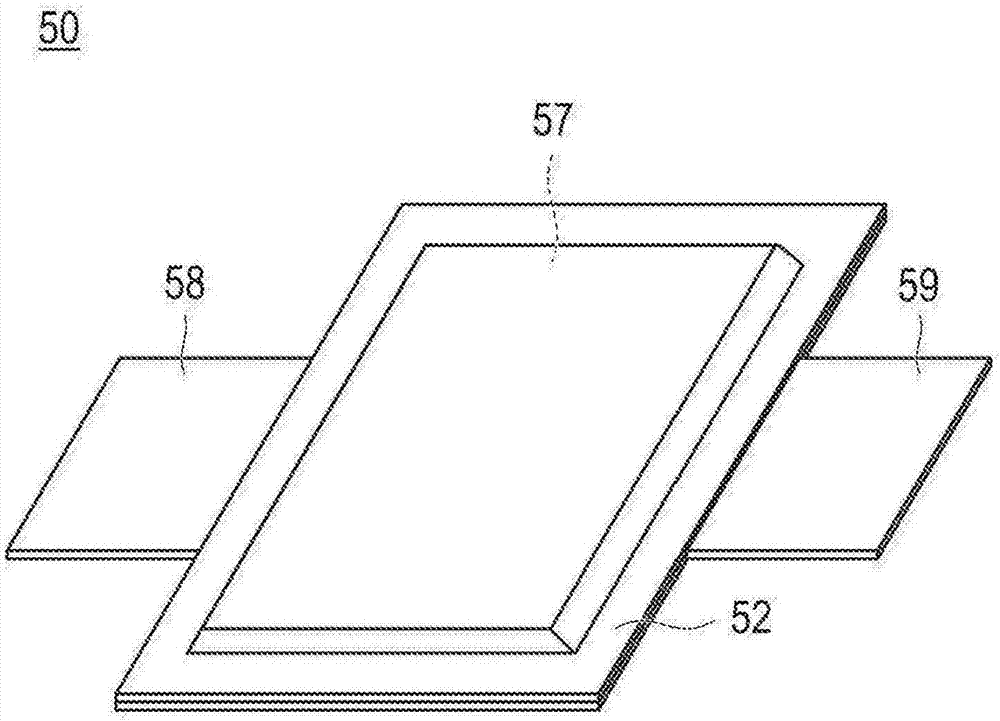

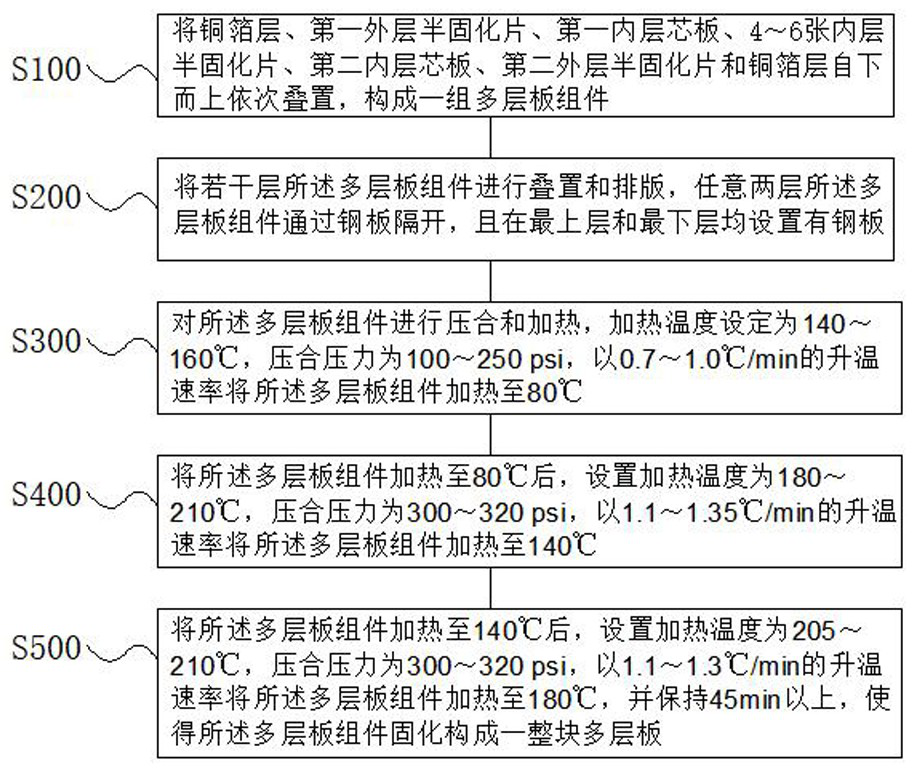

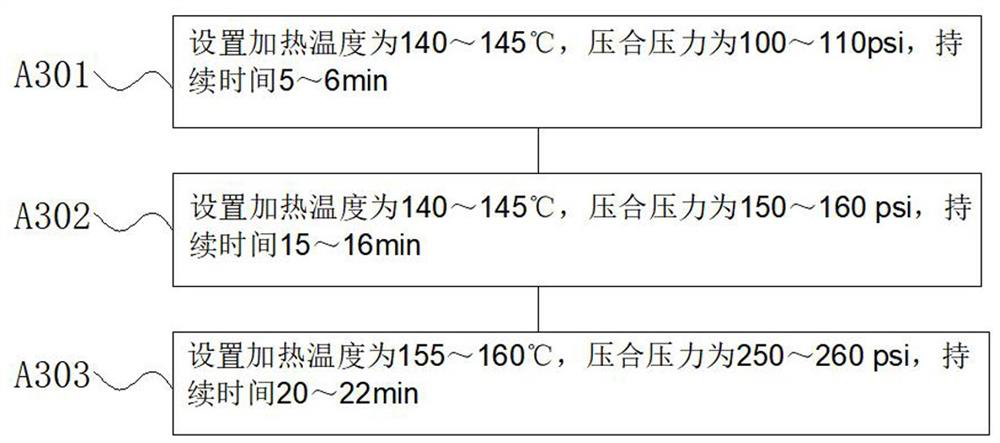

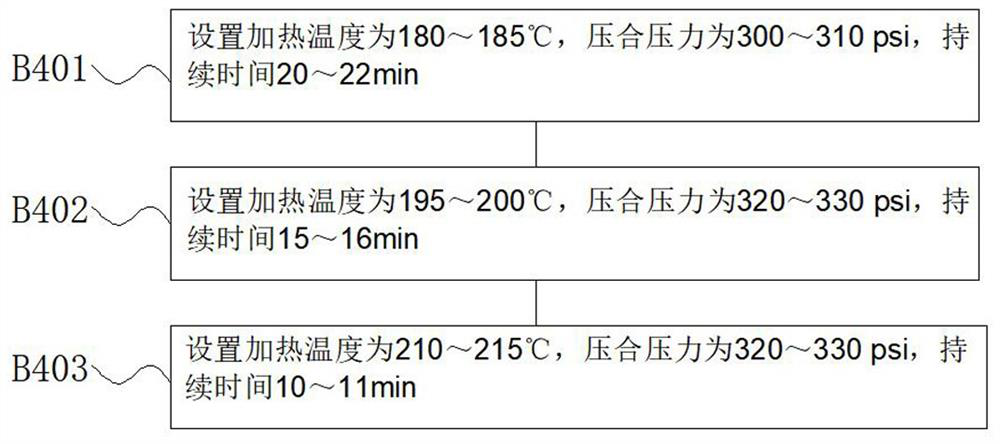

Combined plate pressing process of inner-layer thin core plate and multi-layer prepregs

ActiveCN113630990AEffective control of glue flowControl flow rateMultilayer circuit manufactureEngineeringCopper foil

The invention relates to the technical field of printed circuit plate pressing plates, in particular to a combined plate pressing process of an inner-layer thin core plate and multi-layer prepregs. By means of the plate pressing process, the appropriate glue flowing amount of the prepregs during plate pressing can be effectively controlled, it can be guaranteed that gaps between inner-layer lines are completely filled, air is exhausted, the problems of layer deviation, expansion and shrinkage, and difficult control over plate thickness uniformity and the like caused by pulling due to too large glue flowing when the inner-layer thin core plate is pressed into the multi-layer prepregs can be solved. Meanwhile, the problem of plate thickness caused by too small flowing glue is avoided, and the thickness uniformity of the plate is ensured by controlling the proper flowing glue amount, so that each inner-layer core plate and the copper foil can be completely bonded and further cured to form a whole multi-layer plate, the phenomena of no layering and plate explosion, no texture exposure, no white points, no glue shortage, no bubbles and the like on the plate surface through etching inspection are ensured, accurate control is achieved, and finally it is guaranteed that the multi-layer plate has good electrical performance and mechanical performance.

Owner:HUIZHOU XINGSHUNHE ELECTRONICS CO LTD

Electric hoist

InactiveCN105253796AAvoid expansion and contractionPrevent disengagementWinding mechanismsEngineeringConductor Coil

Owner:TIANJIN TIANYI VALVE

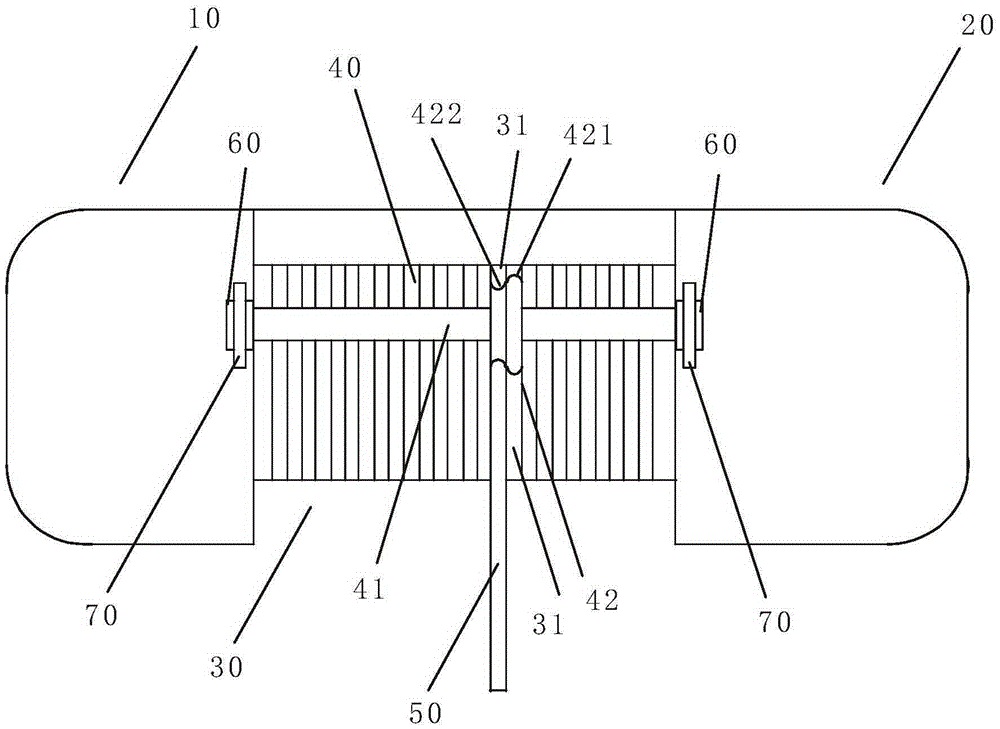

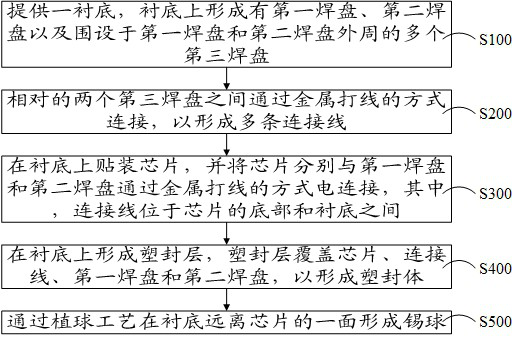

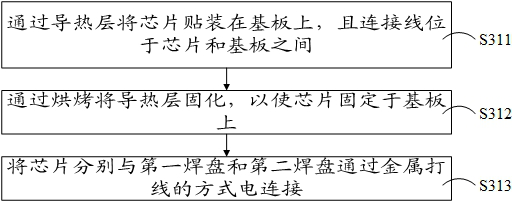

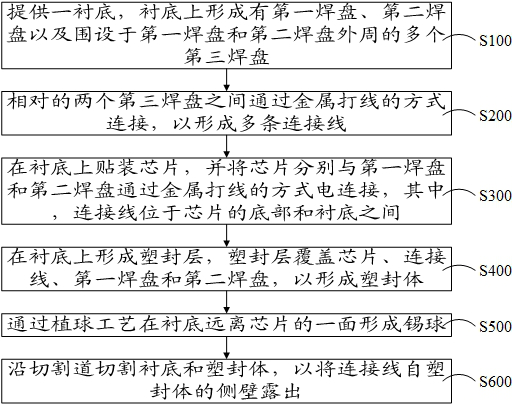

Semiconductor package structure and manufacturing method thereof

ActiveCN112992810BReduce volumeEffective coolingSemiconductor/solid-state device detailsSolid-state devicesPlastic packagingSemiconductor package

A semiconductor packaging structure and a manufacturing method thereof relate to the technical field of semiconductor packaging. The manufacturing method includes providing a substrate on which a first bonding pad, a second bonding pad, and a plurality of third bonding pads surrounding the periphery of the first bonding pad and the second bonding pad are formed; The three pads are connected by metal bonding to form multiple connection lines; the chip is mounted on the substrate, and the chip is electrically connected to the first pad and the second pad by metal bonding , wherein the connecting wire is located between the bottom of the chip and the substrate; a plastic encapsulation layer is formed on the substrate, and the plastic encapsulation layer covers the chip, the connecting wire, the first pad and the second pad to form a plastic package; through the ball planting process Solder balls are formed on the side of the substrate away from the chip. The manufacturing method of the semiconductor package structure can improve the heat dissipation effect of packaged products.

Owner:FOREHOPE ELECTRONICS NINGBO CO LTD

Interlayer interconnection technology

InactiveCN106255346ASimple stepsAvoid expansion and contractionPrinted element electric connection formationCircuit laminationHot pressWire bonding

The invention relates to the field of circuit board manufacture and specifically an interlayer interconnection technology. A technical solution of the interlayer interconnection technology comprises the following steps: a copper surface is subjected to coarsening operation, gold protrusions are manufactured on the copper surface which needs to be interconnected via a wire bonding device, the gold protrusions range from 50 um to 70 um in height, the copper surface is covered with an adhesive layer which is 25 um is thickness, another copper face is hot-pressed on the copper surface in an aligned manner at a temperature of 140 DEG C incessantly for 4 hours, and interlayer connection can be accomplished. The beneficial effects of the interlayer interconnection technology are that procedural complexity in technologies of the prior art can be overcome, a problem that great effects are exerted on product swelling and shrinking by wet manufacture processes can be solved, a dry manufacture process solution is adopted in the interlayer interconnection technology, only simple steps are needed, and a problem of product swelling and shrinking can be prevented.

Owner:山东蓝色电子科技有限公司

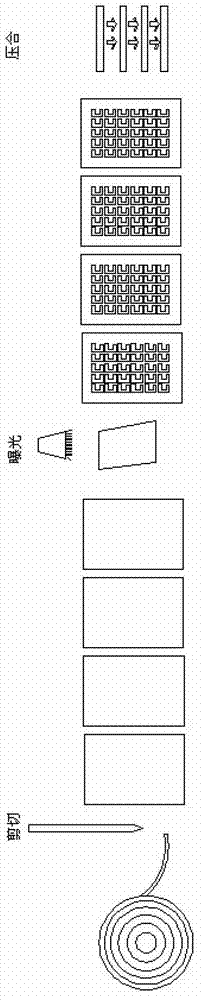

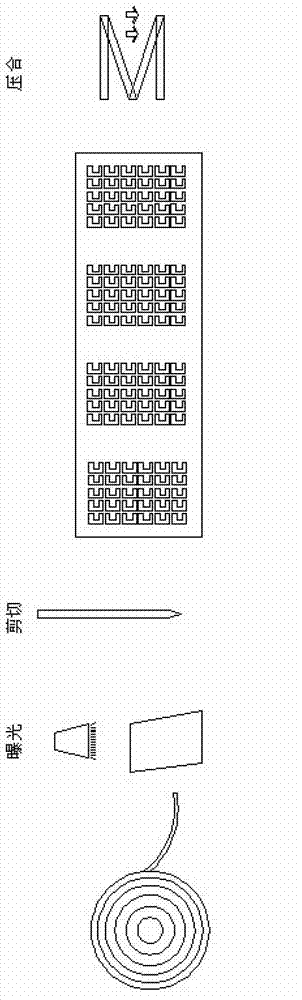

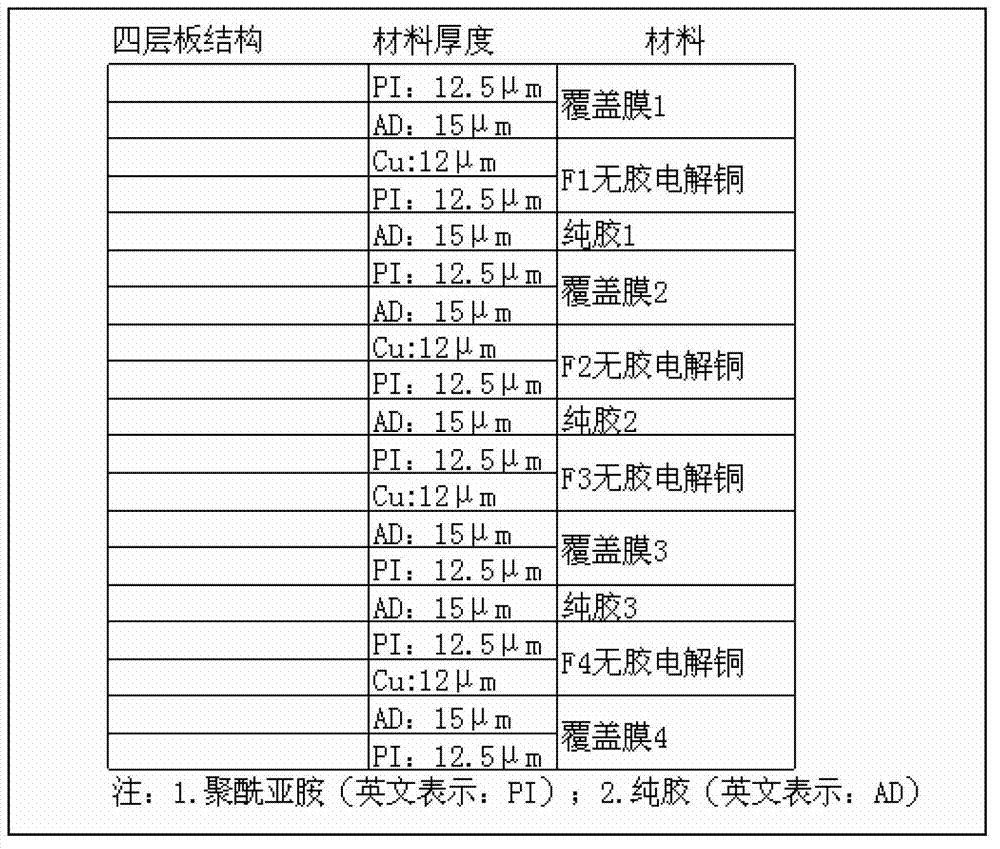

One-step forming method of inner layer circuit of multi-layer flexible circuit board

ActiveCN103079365BImprove qualityAvoid expansion and contractionMultilayer circuit manufactureProduction rateFlexible circuits

The invention discloses a method for once molding an inner-layer line of a multilayer flexible circuit board, and technical problems to be solved are improving the production efficiency and the qualified rate of products. The method for once molding the inner-layer line of the multilayer flexible circuit board comprises the following steps of: pasting a dry film in a whole roll, manufacturing an inner-layer line board of a multilayer board of a flexible circuit board, manufacturing an inner-layer line-board layer, manufacturing an inner-layer line-board combined layer, and manufacturing the inner-layer line of the multilayer flexible circuit board. Compared with the prior art, the processing flows of dry-film pasting, exposing, developing, etching, film removing, microetching and pressing are adopted by the invention to manufacture the inner-layer line board, the inner-layer line-board layer, the inner-layer line-board combined layer and the multilayer flexible circuit board, so that problems of height drop generated between a glued area and a non-glue area after inner-layer soft boards are pressed and expansion and shrinkage of the soft boards caused by pressing an inner-layer covering film for many times are avoided, the quality of the multilayer flexible circuit board is improved, the qualified rate reaches more than 92 percent, the process flow is shortened, and the production rate is improved.

Owner:SHENZHEN XINYU TENGYUE ELECTRONICS

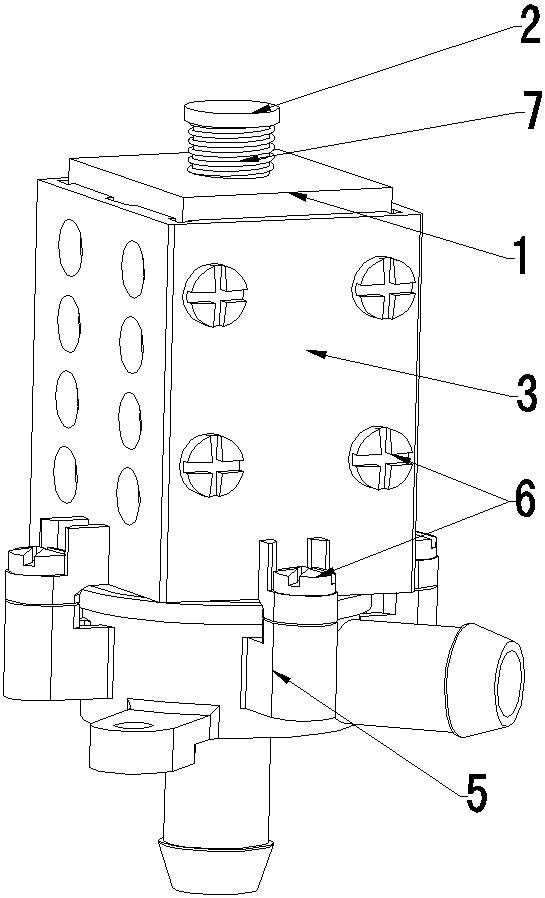

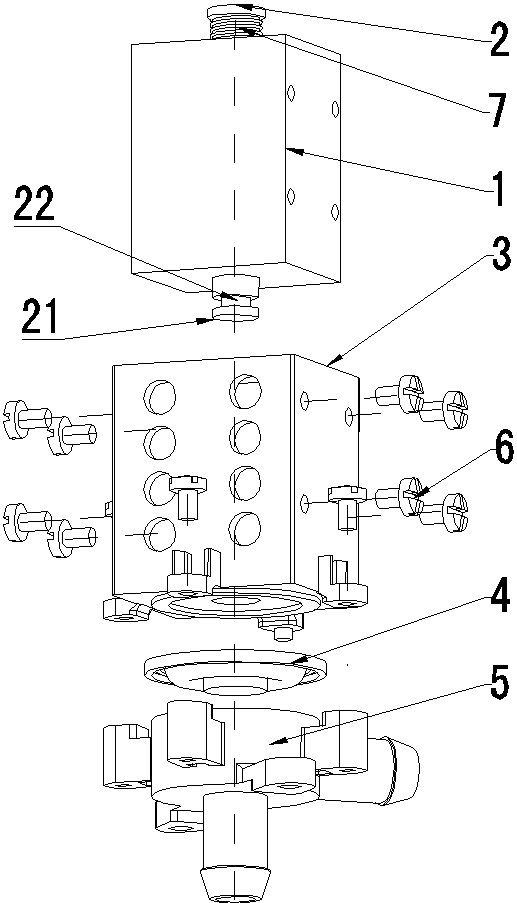

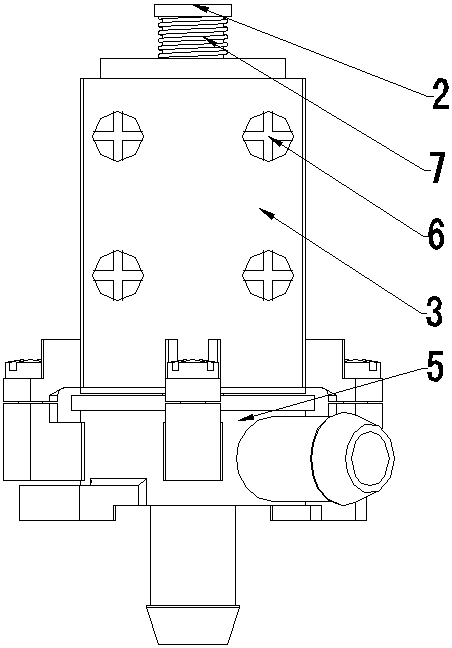

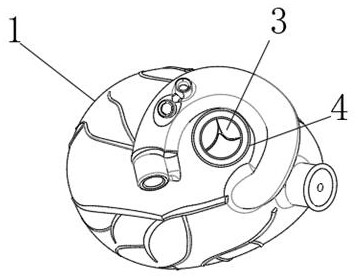

Pressure electromagnetic valve

PendingCN107631053AExtended service lifeEasy to useDiaphragm valvesEngine diaphragmsInlet channelElectromagnetic valve

The invention discloses a pressure electromagnetic valve, which comprises an electromagnetic valve body, a valve body, a fixing upper cover, a sealing gasket and a fixing lower cover. A plurality of installation holes are formed in two side surfaces of the electromagnetic valve body and two side surfaces of the fixing upper cover; the electromagnetic valve body is arranged in the fixing upper cover and fixed through screws; the valve body penetrates through the electromagnetic valve body; a reset spring is arranged at the upper part of the valve body; the sealing gasket is arranged between thefixing upper cover and the fixing lower cover; the fixing upper cover and the fixing lower cover are fixed through screws; the fixing lower cover comprises a fixing lower cover body, a liquid / air inlet channel and a liquid / air outlet channel; the liquid / air inlet channel and the liquid / air outlet channel are fixedly connected with the fixing lower cover body; a holding cavity is arranged in the fixing lower cover body; a liquid / air outlet of the liquid / air inlet channel stretches into the holding cavity; and the liquid / air inlet channel and the liquid / air outlet channel communicate through the holding cavity. According to the pressure electromagnetic valve provided by the invention, an application field and an application range of the pressure electromagnetic valve are greatly enlarged, and the service life of the pressure electromagnetic valve is prolonged.

Owner:ZHONGSHAN HUANUO ELECTRIC CO LTD

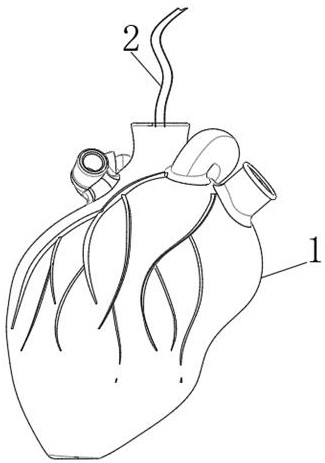

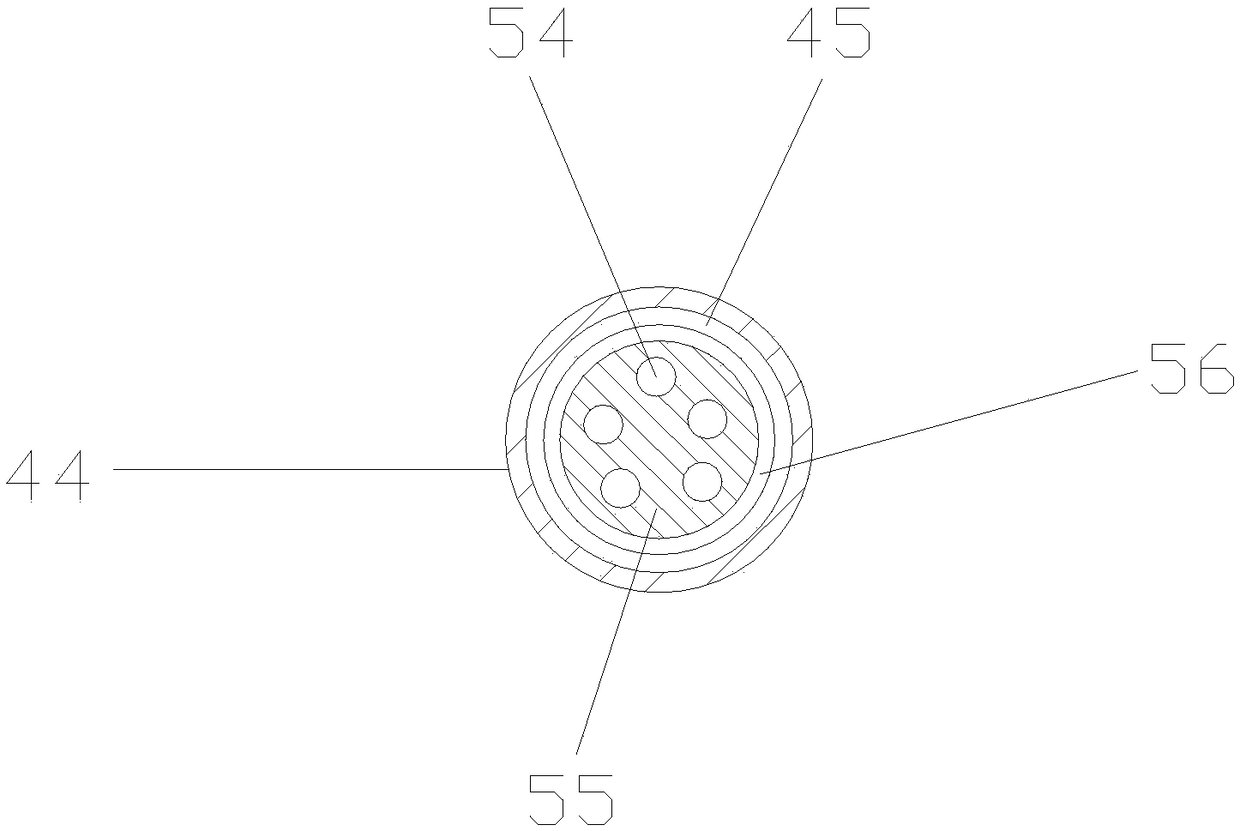

Anti-deformation medical tube capable of self-adapting to internal pressure environment of human body

The invention discloses an anti-deformation medical tube capable of self-adapting to the internal pressure environment of a human body. The anti-deformation medical tube comprises a heart and a catheter, wherein a femoral artery interface is formed in the femoral artery part of the heart, an aortic valve is arranged on the inner cavity wall of the femoral artery interface, the catheter is inserted in the middle of the aortic valve, a second tube wall sliding head is connected to the outer wall of the catheter in a sliding mode, a middle tube is fixedly connected to the bottom end of the second tube wall sliding head, and a first tube wall sliding head is fixedly connected to the bottom end of the middle tube. According to the anti-deformation medical tube capable of self-adapting to the internal pressure environment of the human body, the catheter is inflated, part of gas is guided into an inner cavity of a cavity rubber tube through a through hole formed in the catheter, the cavity rubber tube in the inner cavity of the cavity rubber tube is pushed to push an expansion frame to move outwards, and the expansion frame is controlled to push a nickel-titanium alloy body to be attached to the inner cavity opening wall of the femoral artery interface.

Owner:XIANGTAN UNIV +1

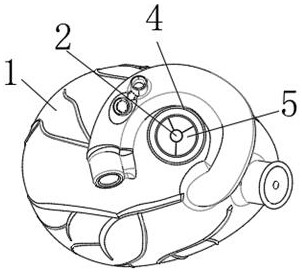

Wooden ground heating floor with heating function

InactiveCN108756134AAdjust the temperature freelyComfortable temperatureLighting and heating apparatusElectric heating systemFiberPower cable

The invention discloses a wooden ground heating floor with a heating function. The wooden ground heating floor with the heating function comprises a floor body, and a false tongue and tongue-and-groove which are matched are separately arranged at two ends of the floor body. The false tongue includes a connecting tongue, a first groove is formed in the upper end of the connecting tongue, and a second groove is formed in the lower end of a connecting groove. The tongue-and-groove includes the connecting groove, a first locking protrusion is arranged at the upper end of the connecting groove, anda second locking protrusion is arranged at the lower end of the connecting groove. A heating layer is arranged inside the floor body, a hollow groove is formed in the heating layer, a plurality of vertical isolation ribs are arranged in the hollow groove, and reinforcing ribs arranged crosswise are arranged between the adjacent isolation ribs, and the intersection parts of the reinforcing ribs isprovided with threading pipes, carbon fiber heating wires are arranged in the threading pipe, the carbon fiber heating wires are centrally connected to an external temperature controller through a cold lead, and a power cable is connected to the temperature controller. The wooden ground heating floor with the heating function has the characteristics of good heating effect, high connection strength, convenient installation and maintenance and good comfort.

Owner:湖州春阁家居科技有限公司

Negative electrode active material for electrical equipment and electrical equipment using same

ActiveCN107112518BAvoid expansion and contractionHigh cycle durabilityNegative electrodesLi-accumulatorsElectrical batterySilicon alloy

[Problem] Provide a proposal that can improve the cycle durability of electric equipment such as lithium-ion secondary batteries. [Solution] A negative electrode active material having a structure in which a silicide containing a transition metal is dispersed in a parent phase mainly composed of amorphous or low-crystallinity silicon is used for an electric device. The phase structure includes a silicon-containing alloy having a predetermined composition, and the diffraction peak intensity B of a transition metal silicide in the range of 2θ=37 to 45° in X-ray diffraction measurement using CuKα1 rays of the silicon-containing alloy The value (B / A) of the ratio (B / A) of the diffraction peak intensity A to the (111) plane of Si in the range of 2θ=24 to 33° is 0.41 or more.

Owner:NISSAN MOTOR CO LTD

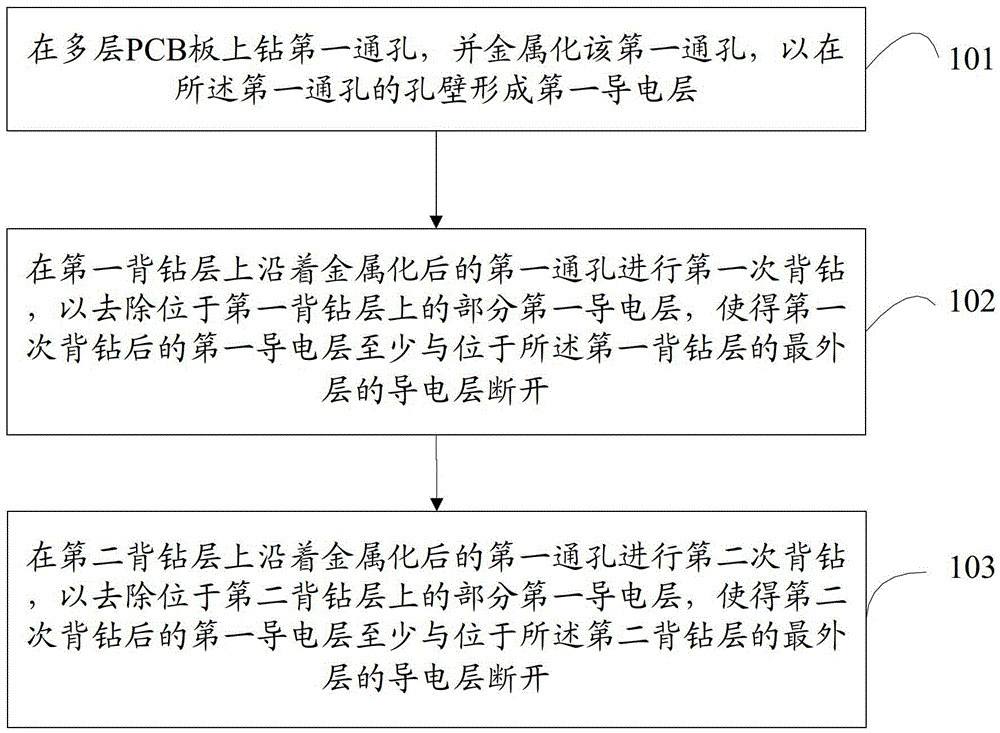

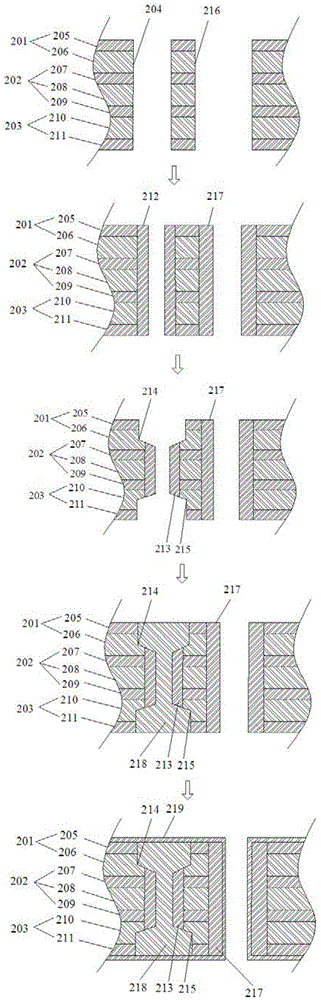

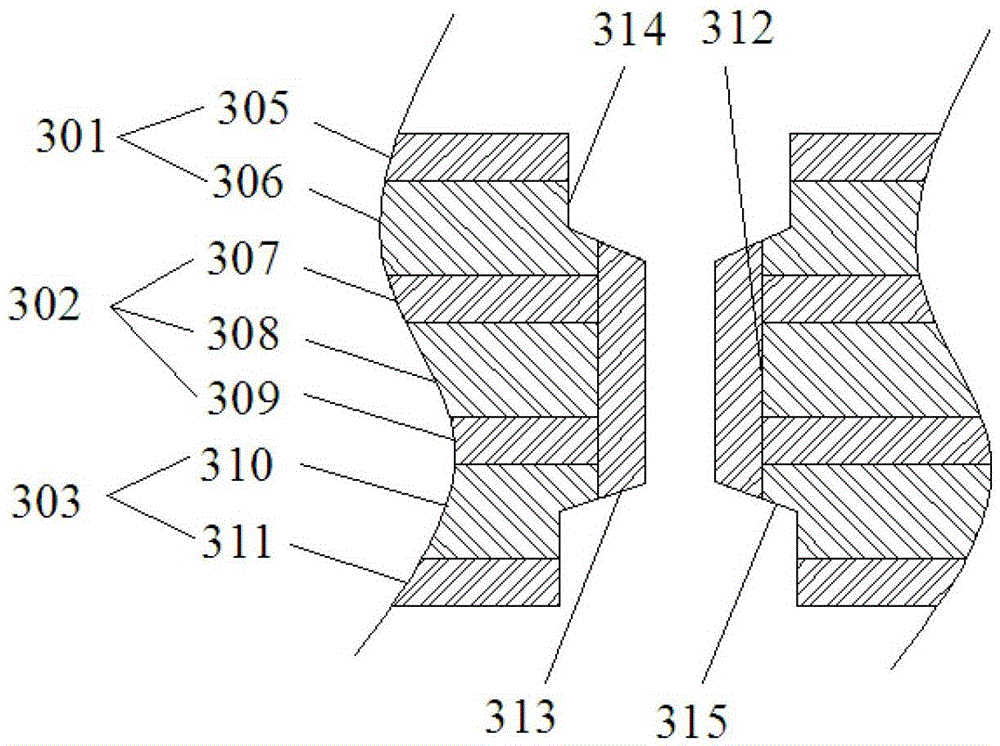

A kind of multilayer pcb board manufacturing method and multilayer pcb board

ActiveCN103517581BAchieve connectionIncrease productivityPrinted circuit detailsMultilayer circuit manufactureEngineeringDrill

The invention discloses a method for manufacturing a multilayer PCB board, which mainly includes: drilling a first through hole on a multilayer PCB board, and metallizing the first through hole to form a first hole wall on the first through hole wall. Conductive layer; perform first backdrilling on the first backdrilling layer along the metallized first through hole to remove part of the first conductive layer located on the first backdrilling layer; on the second backdrilling layer A second back-drilling is performed along the metallized first through hole to remove part of the first conductive layer on the second back-drilled layer. The invention also provides a corresponding multi-layer PCB board. The method of the present invention is by making conductive through-hole on multi-layer PCB board, and removes the part conductive layer of conductive through-hole with the mode of back-drilling, so that the conductive through-hole after back-drilling only connects the conductive layer of lamination, and does not connect with back-drilling. The conductive layer of the drilling layer is disconnected, which realizes the connection between the conductive layers of the stacked layers of the multi-layer PCB board, improves the production efficiency, and reduces the difficulty of alignment.

Owner:SHENNAN CIRCUITS

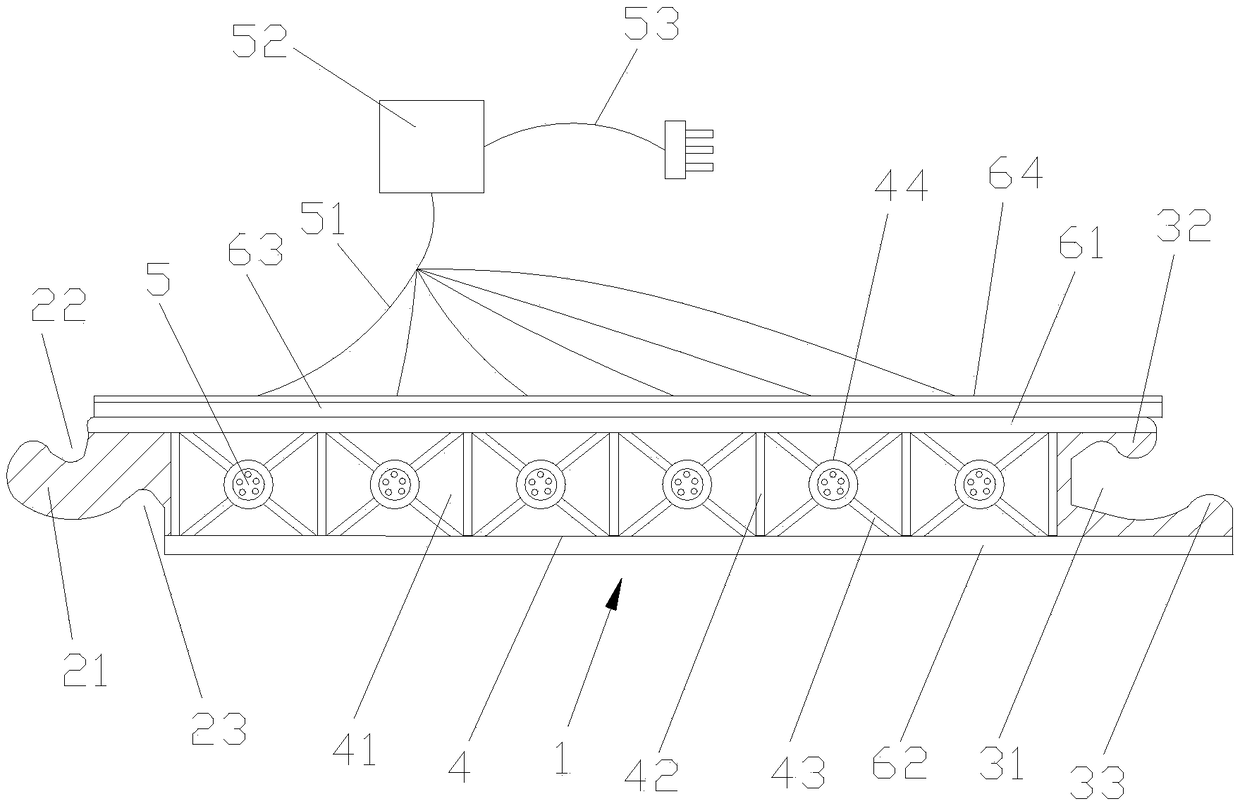

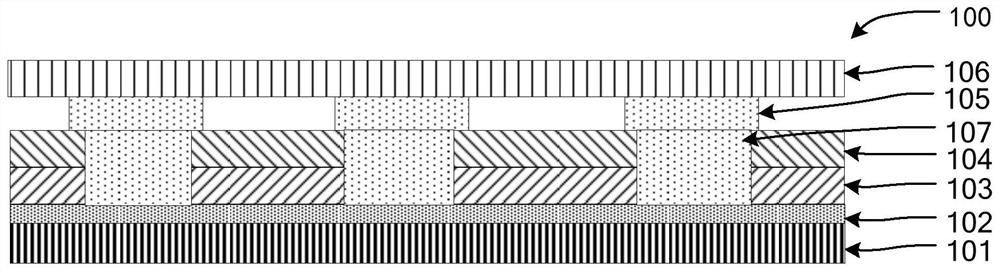

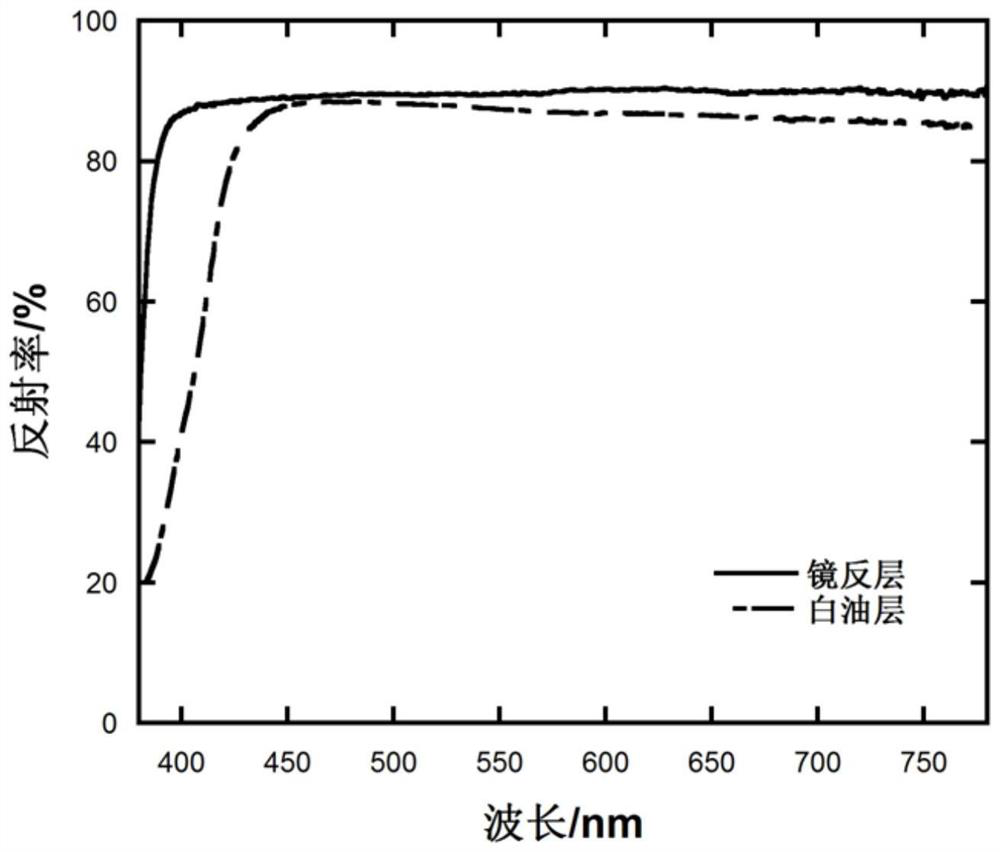

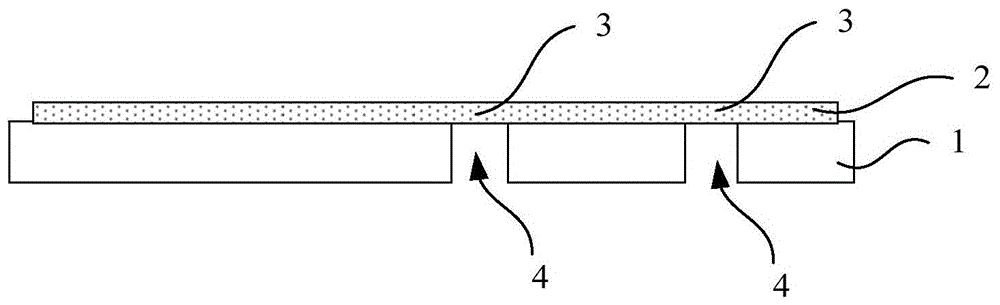

Surface light source, its preparation method and display device using the surface light source

ActiveCN109065529BImprove reflectivityHigh light efficiencySolid-state devicesNon-linear opticsFluorescenceDisplay device

The invention discloses a surface light source, its preparation method and a display device using the surface light source. The surface light source includes a substrate; a wire layer with several wires distributed on a surface of the substrate; a mirror reflection layer, covered on the wire layer; a high temperature resistant film layer, covered on the specular reflection layer; a number of LED chips, distributed on the high temperature resistant film layer and correspondingly connected to the wire; a fluorescent A film covering the LED chip and the high temperature resistant film layer. The surface light source, the preparation method thereof and the display device using the surface light source of the present invention effectively improve the reflectivity and overall light efficiency of the surface light source.

Owner:WUHAN CHINA STAR OPTOELECTRONICS TECH CO LTD

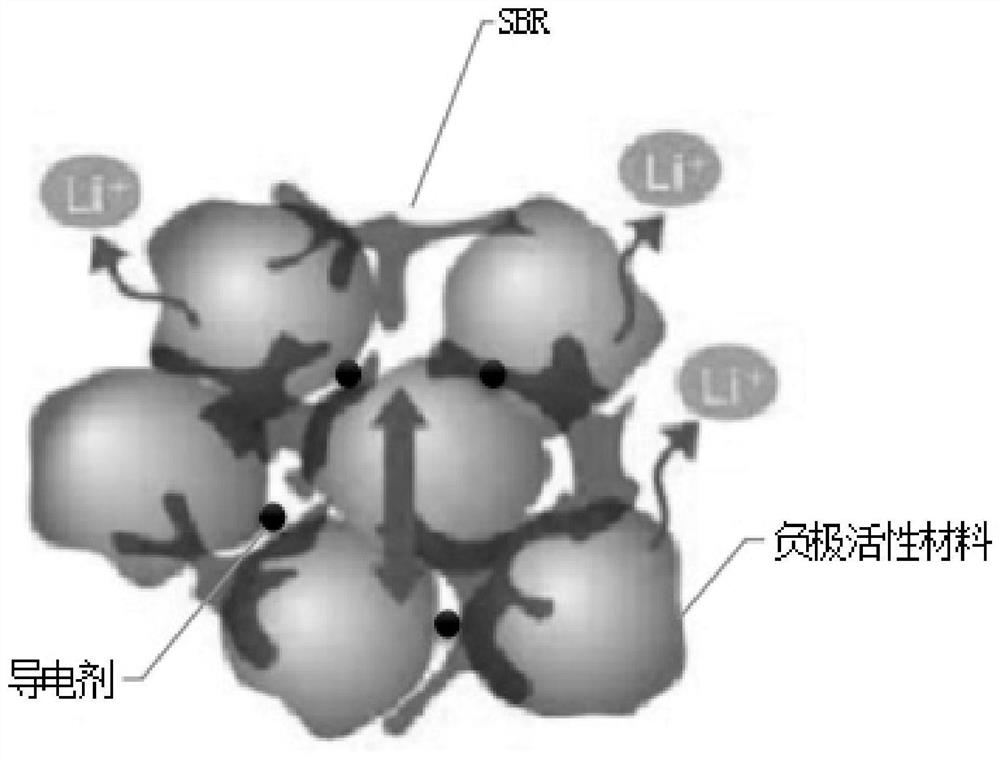

Lithium-ion battery negative electrode slurry, preparation method thereof, negative electrode sheet, and lithium-ion battery

ActiveCN110828789BImprove high temperature storageImprove cycle performanceCell electrodesSecondary cellsElectrical batteryCharge and discharge

The invention relates to the technical field of lithium-ion batteries, and specifically provides a lithium-ion battery negative electrode slurry, a preparation method thereof, a negative electrode sheet, and a lithium-ion battery. The negative electrode slurry of the lithium ion battery comprises a negative electrode active material, a conductive agent, a binding agent, a thickener and deionized water, wherein the negative electrode active material is a silicon-based material; the D50 particle diameter of the conductive agent is (0.05~5 ) μm; the binder is styrene-butadiene rubber, and the modulus of elasticity of styrene-butadiene rubber is (1.25-5.0) MPa. In the present invention, the styrene-butadiene rubber with a specific elastic modulus and the conductive agent with a specific D50 particle size make the lithium-ion battery negative electrode slurry exhibit a very high elastic effect when it is coated to form a negative electrode sheet, and can effectively inhibit the expansion of silicon-based materials. Further inhibit the destruction of the SEI film, thereby improving the electrochemical performance of the battery such as high-temperature storage, cycle performance, and high-rate charge and discharge.

Owner:DONGGUAN CHUANGMING BATTERY TECH

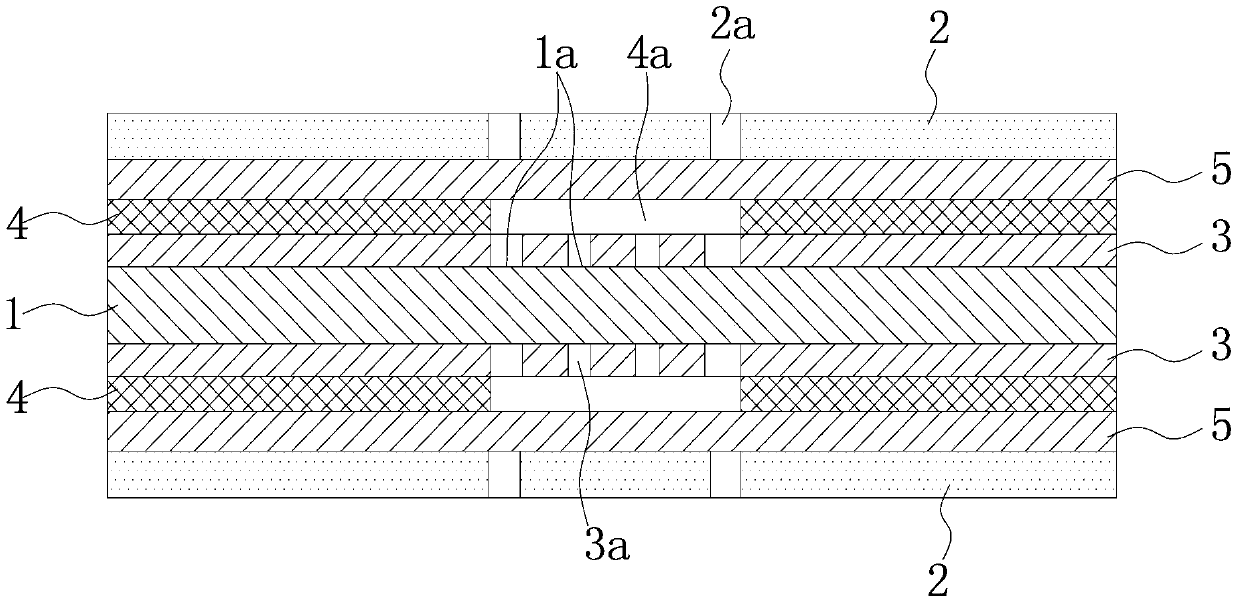

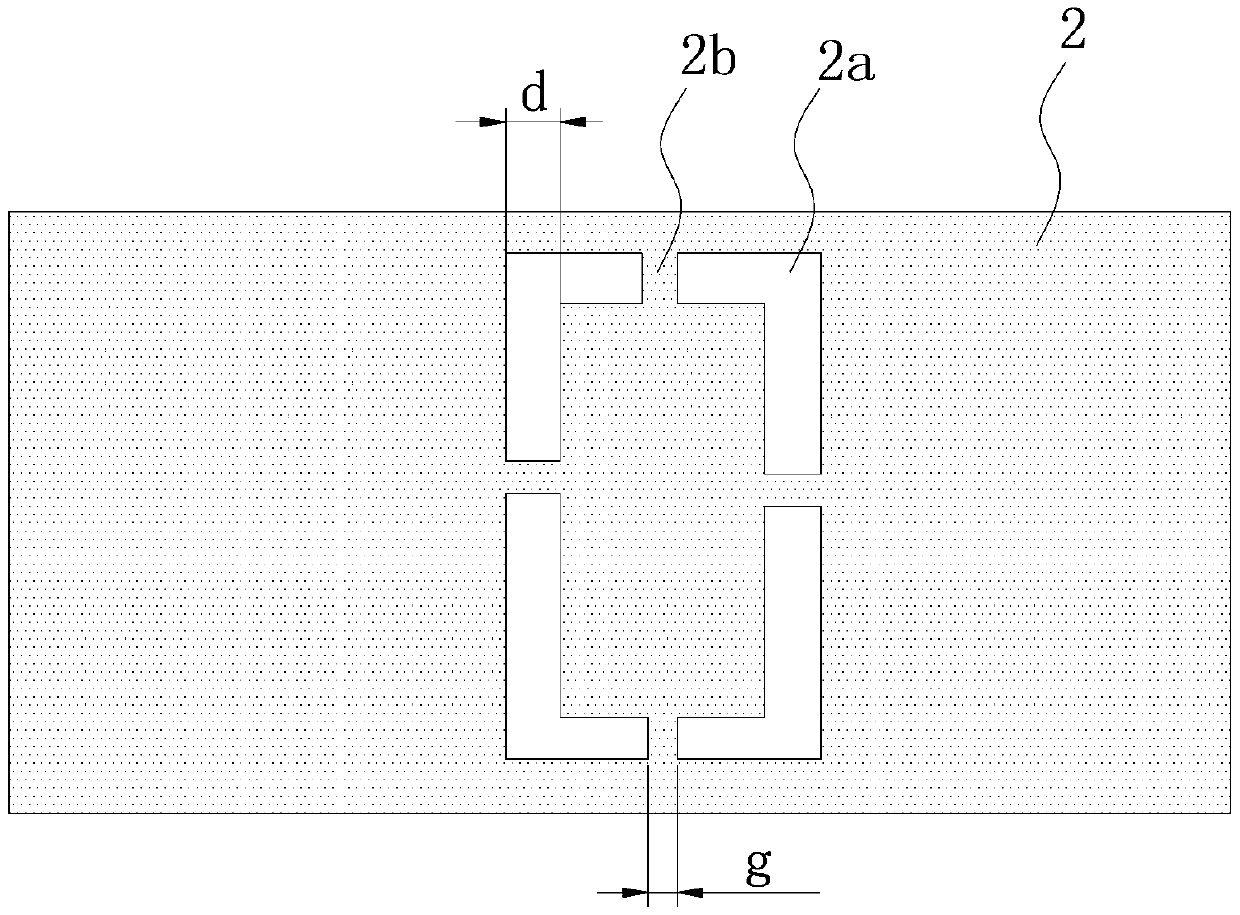

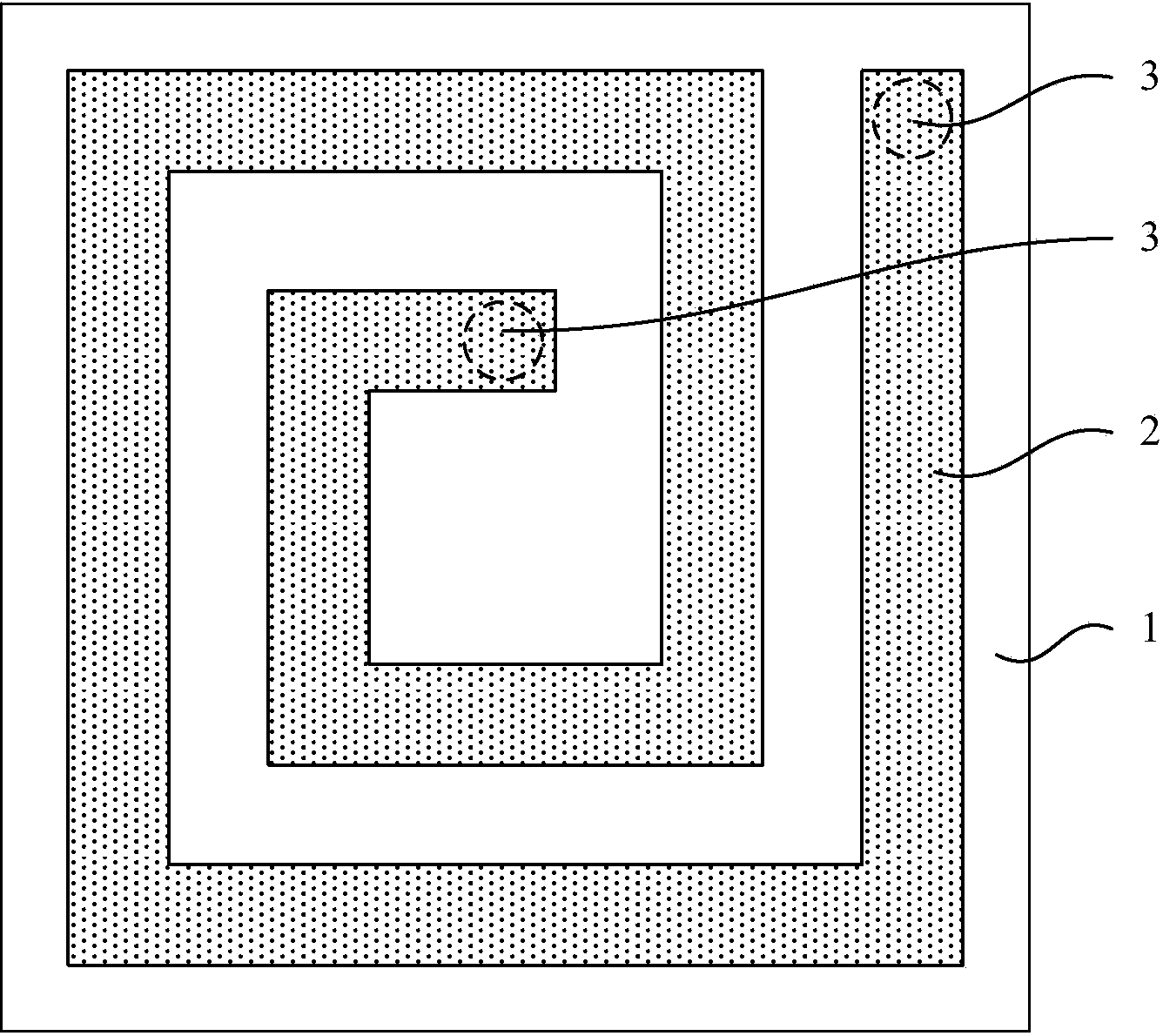

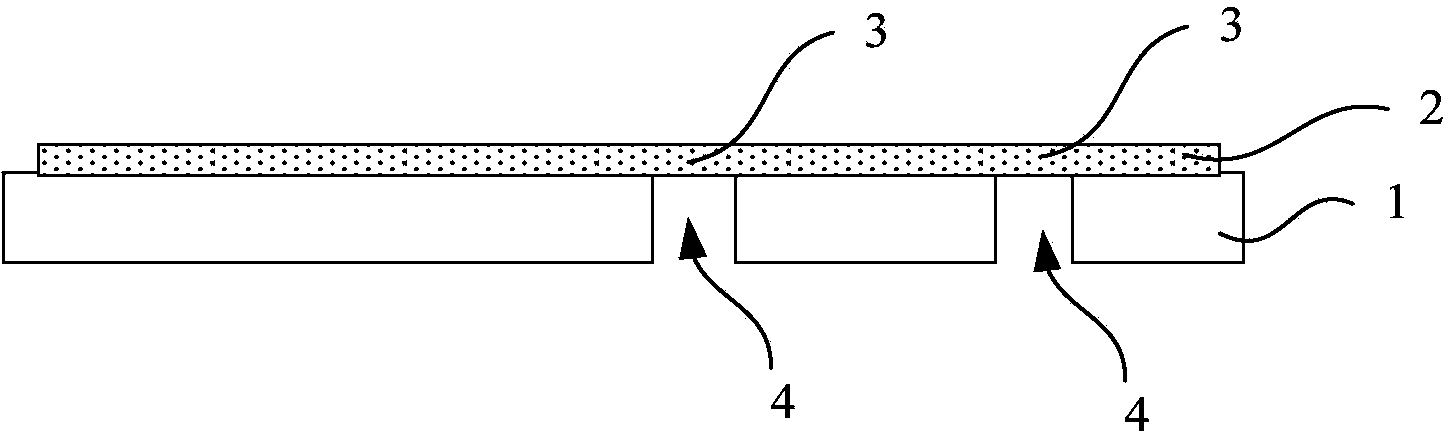

Rigid-flex board for protecting inner layer window opening area and manufacturing method thereof

ActiveCN103384444BAvoid enteringImprove yieldPrinted circuit manufactureElectrical connection printed elementsWindow openingProtection layer

Owner:BOMIN ELECTRONICS CO LTD +1

Method for manufacturing resin plug hole of thin PCB

ActiveCN112533378AAvoid expansion and contractionAvoid Denting the OrificePrinted circuit manufactureMechanical engineeringComposite material

The invention discloses a manufacturing method of a thin PCB resin plug hole. The manufacturing method comprises the following steps of firstly, performing resin plug hole on a PCB by using a double-sided jig and an air guide cushion plate; after hole plugging is completed, the PCB and the double-sided jig being baked together; after baking is completed, the double-sided jig being polished; afterpolishing is completed, laser being used for ablating resin in the hole; the double-sided fixture is removed, and the method enter the subsequent production process. The concept of the laminated boardis creatively provided, the rigid jigs are additionally arranged on the two faces of the PCB to form the laminated board, due to the fact that the rigidity of the laminated board is large, resin on the surface of the laminated board can be removed through mechanical polishing, the resin on the surface of the laminated board is made to be located on the same plane, and then laser ablation is conducted; According to the method, problems of large expansion and shrinkage of the board, hole sinking, board surface pits and the like during resin grinding of the PCB made of the traditional PTFE material can be effectively avoided.

Owner:ANHUI SUN CREATE ELECTRONICS

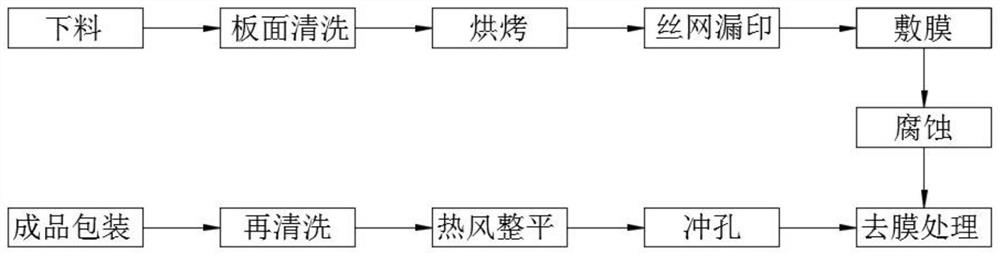

Binding board thick frame printing process

InactiveCN112055473AEasy to controlSmall side erosionPrinted circuit liquid treatmentConductive pattern formationSolder pasteMegasonic cleaning

The invention discloses a binding board thick frame printing process, and particularly relates to the technical field of circuit board printing, the binding board thick frame printing process comprises the following steps: S1, blanking, specifically, cutting a substrate into a required shape to prepare a binding board; s2, plate surface cleaning, specifically, putting the binding board into water,and cleaning the binding board in an ultrasonic cleaning mode; s3, baking, specifically, bakingthe cleaned binding board, and drying water; s4, silk screen skip printing, specifically, printing a required circuit diagram on the binding board through silk screen skip printing lead-free solder paste; and S5, coating, specifically, coating the binding board with a circuit diagram protection film, and preparing for corrosion. According to the circuit board printing process, printing is conducted on the binding board, board explosion and expansion and contraction are avoided through cleaning and drying, corrosion is achieved through spraying of spray heads, control is easy, lateral corrosion is small, the binding board can be effectively protected through hot air leveling, flaws are avoided when the high-precision circuit board is produced, the product reliability is high, and the production cost can be controlled at the normal level.

Owner:东莞市高迈电子有限公司

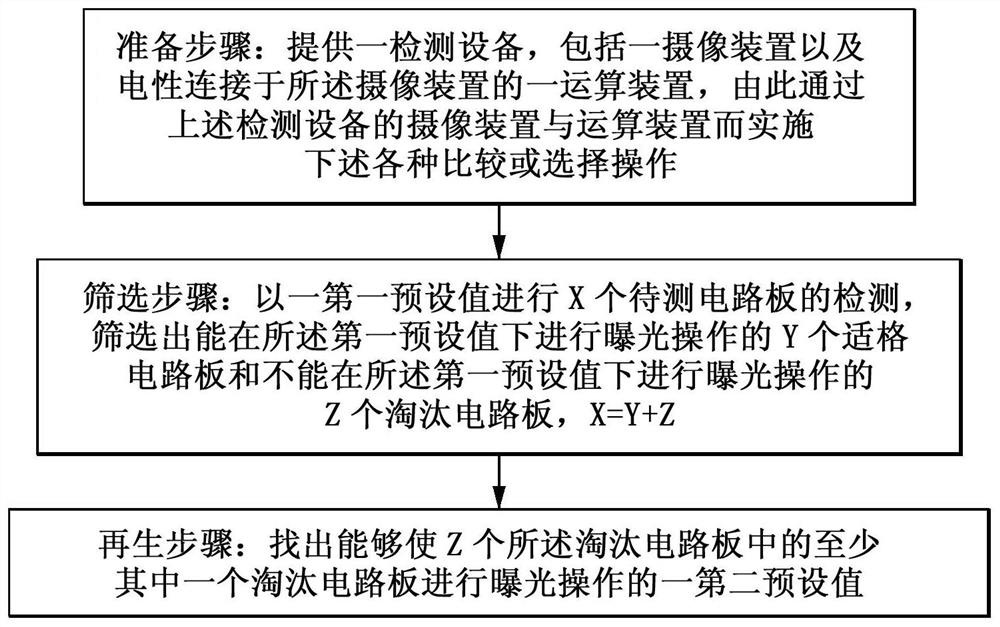

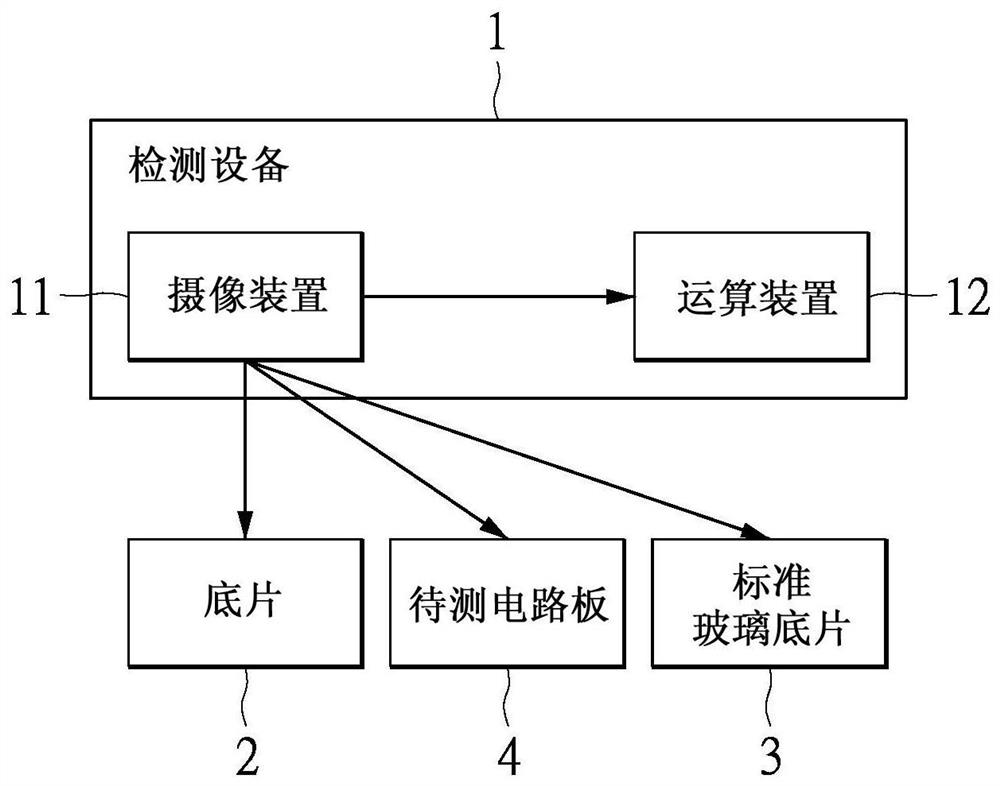

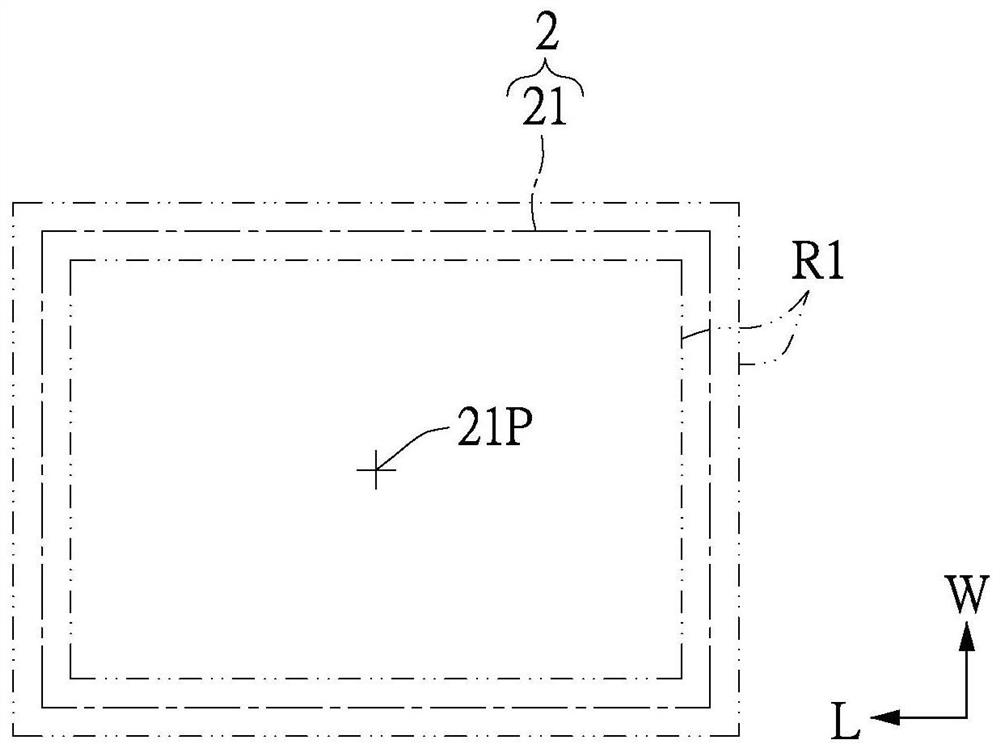

Circuit board detection method

InactiveCN111163586BAvoid expansion and contractionExtended service lifePrinted circuit manufactureThermodynamicsProcess engineering

The invention discloses a circuit board detection method. The circuit board detection method includes: a screening step, a regeneration step and an exposure step; A qualified circuit board for exposure operation under the first preset value, and an eliminated circuit board that cannot perform exposure operation under the first preset value; A second preset value, and the second preset value is relative to a second film; the exposure step is implemented in an exposure device, and an environment in the exposure device is controlled by an environment control structure The temperature is cooled, so that the Y qualified circuit boards, the first negative, the at least one eliminated circuit board, and the second negative can be maintained during the exposure operation in the exposure equipment. The ambient temperature is below a predetermined temperature.

Owner:C SUN MFG

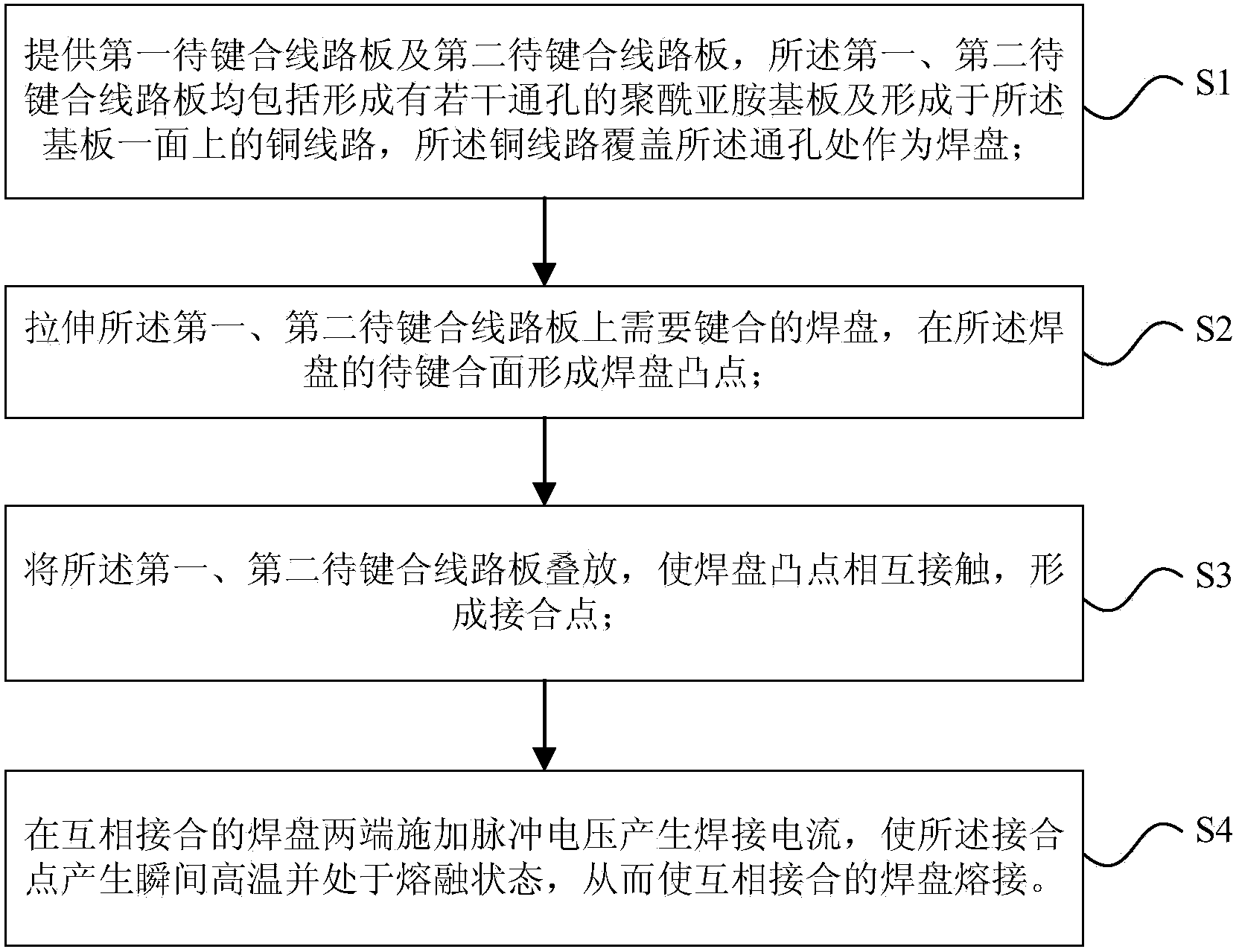

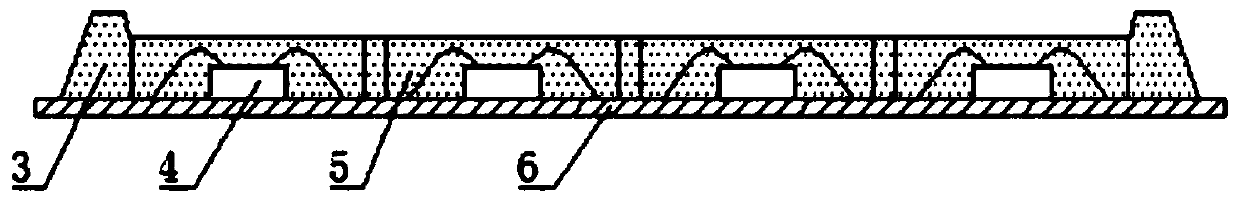

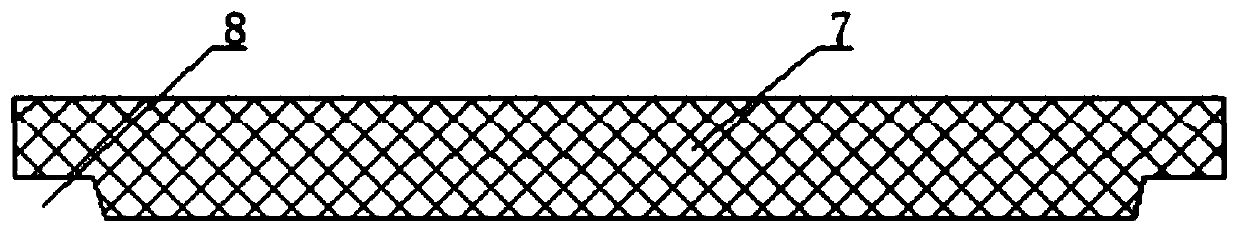

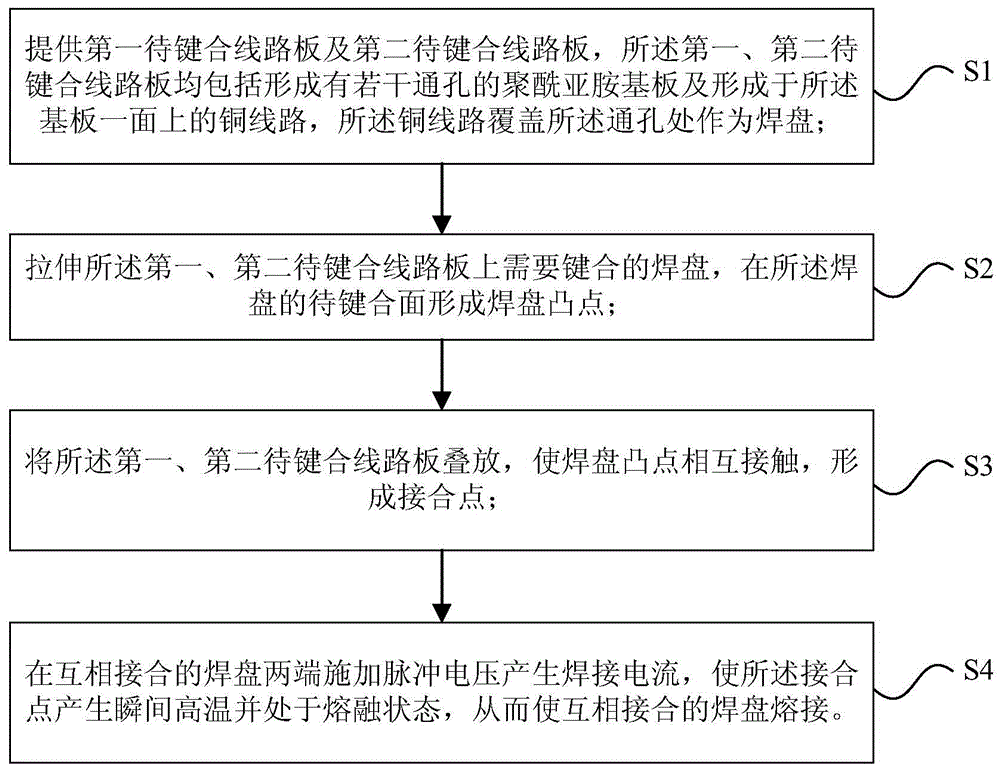

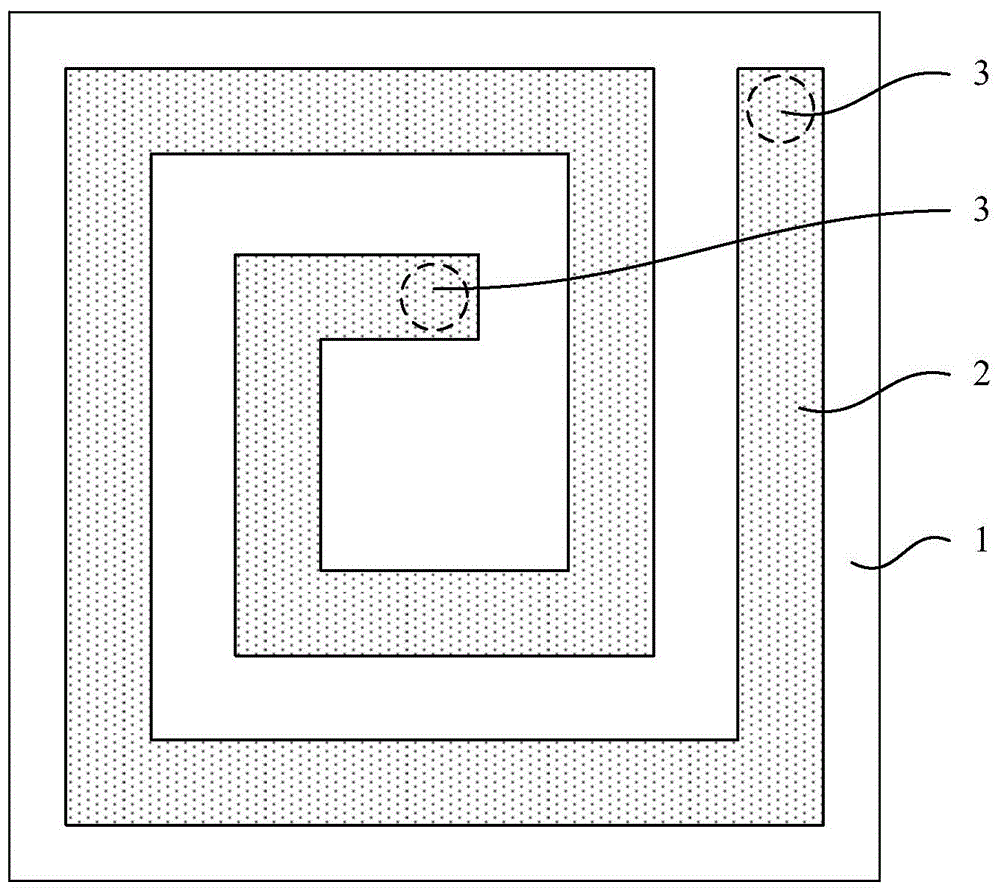

Flexible circuit board manufacturing method

ActiveCN104168725AReduce cost pressureReduce processing costsPrinted element electric connection formationMolten stateSocial benefits

The invention provides a flexible circuit board manufacturing method. The flexible circuit board manufacturing method at least comprises the following steps that 1, a first circuit board to be bonded and a second circuit board to be bonded are provided, wherein the first circuit board to be bonded and the second circuit board to be bonded respectively comprise a polyimide substrate and a copper line, each polyimide substrate is provided with a plurality of through holes, each copper line is formed on one face of the corresponding substrate, and the copper lines cover the through holes to serve as bonding pads; 2, the bonding pads, needing to be bonded, on the first circuit board to be bonded and the second circuit board to be bonded are stretched, and bonding pad convex points are formed on the to-be-bonded faces of the bonding pads; 3, the first circuit board to be bonded and the second circuit board to be bonded are stacked, so that the bonding pad convex points make contact to form junction points; 4, pulse voltage is exerted on the two ends of the jointed bonding pads so that welding current can be generated, and the junction points are at a high temperature instantaneously and in a molten state, so that the jointed bonding pads are welded in a fusion mode. The bonding pads are welded in the fusion mode in a pulse voltage spot welding mode, the flexible circuit board holes can be communicated and connected, the process is simple and efficient, and meanwhile good economic benefits and social benefits are obtained.

Owner:上海蓝沛信泰光电科技有限公司

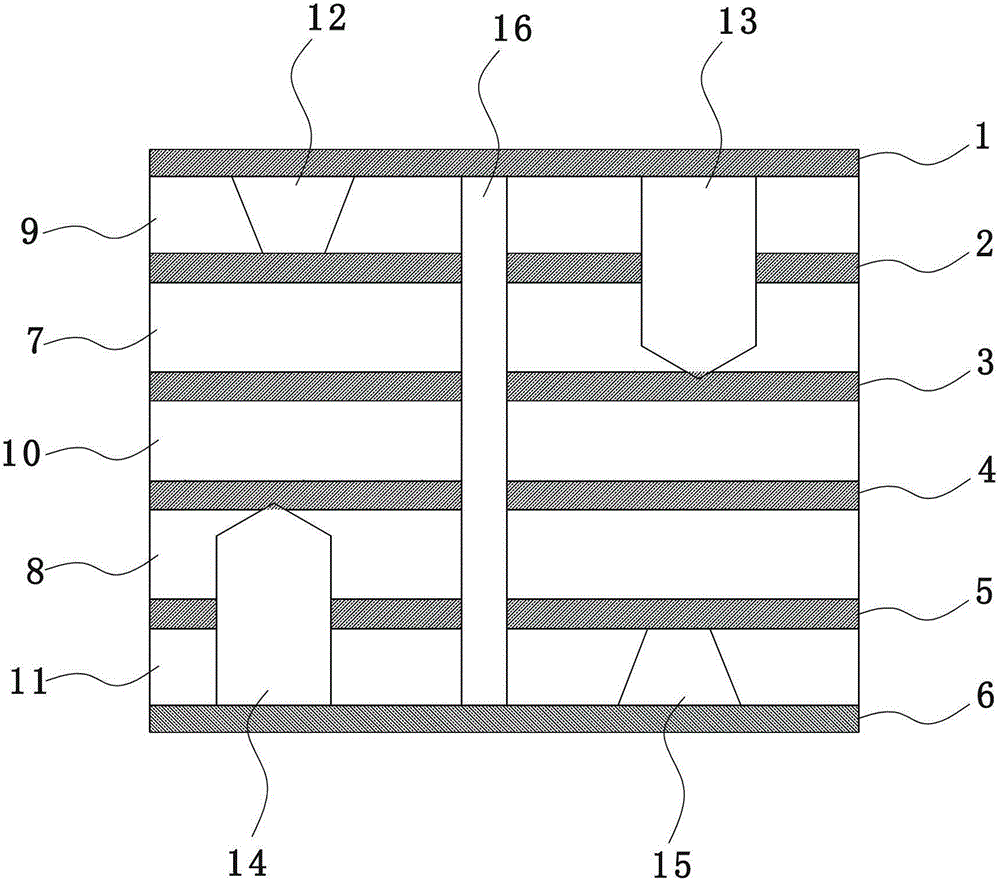

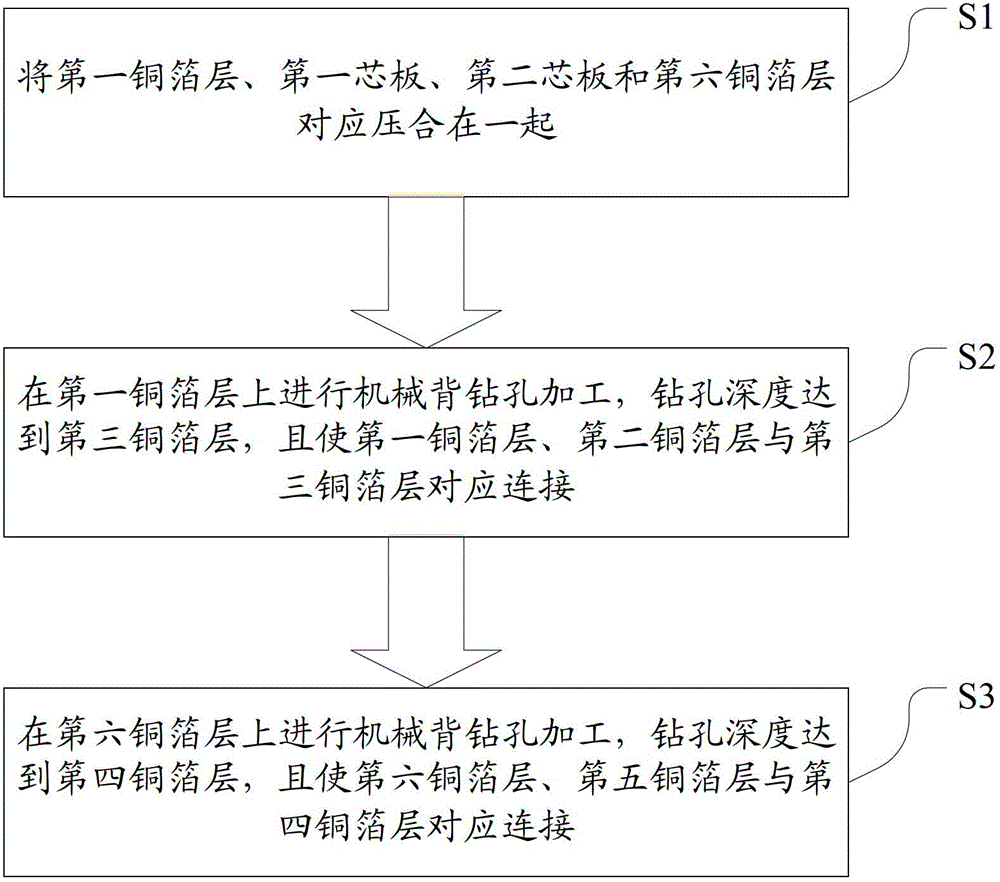

HDI board with mechanical back drilling structure and manufacturing method thereof

ActiveCN103025051BShorten the production cycleAvoid expansion and contractionPrinted circuit detailsMultilayer circuit manufactureHigh densityMetallurgy

The invention further provides a high density interconnect (HDI) plate with a mechanic back drilling structure and a manufacturing method thereof. The method comprises that: S1: a first copper foil layer, a first core plate, a second core plate and a sixth copper foil layer are correspondingly subjected to laminating together; S2: the first copper foil layer is subjected to mechanic back drilling processing with the drilling depth reaching a third copper foil layer, and the first copper foil layer, the second copper foil layer and the third copper foil layer are correspondingly connected; S3: the sixth copper foil layer is subjected to the mechanic back drilling processing with the drilling depth reaching a fourth copper foil layer, and the sixth copper foil layer, a fifth copper foil layer and the fourth copper foil layer are correspondingly connected. By adopting a manufacturing way that two core plates are firstly subjected to the laminating one time and then are subjected to the mechanic back drilling processing one time, the production cycle of the HDI plate is greatly shortened, the production cost is reduced, at the same time, the problem of panel expansion caused by multiple times of laminating, laser drillings and abrasive belt grindings is avoided, and the counterpoint accuracy between layers is guaranteed. Compared with the prior art, the HDI plate has the advantages of simple manufacturing process, high production efficiency, low cost and the like.

Owner:SHENZHEN SUNTAK MULTILAYER PCB

A kind of thick copper board of different types of circuit boards and the manufacturing method of circuit boards

ActiveCN105704914BIncrease productivityIncrease profitMultilayer circuit manufactureCircuit laminationEngineeringCopper

The invention discloses a thick copper plate for different types of circuit boards and a production method for the circuit board. The thick copper plate is of a square structure, and a thick copper plate unit and a connecting area are arranged on the thick copper plate; a gong side and a connecting position are arranged at the outer side of each thick copper plate unit, and each thick copper plate unit is connected to a connecting part through the connecting position; a plurality of locating holes are arranged in the connecting area and are located on a frame of the thick copper plate. The invention also discloses a production method for the circuit board. According to the thick copper plate for different types of circuit boards and the production method for the circuit board, the utilization rate of the board and the production efficiency of the circuit board are effectively improved, the production cost is saved, the waste of the production raw materials is reduced and the fast batch production is realized; meanwhile, the circuit board is directly formed in the thick copper plate and then composing and laminating are carried out without taking an FR4 substrate as a lag, so that the expansion problem of materials of the copper plate and the FR4 substrate after laminating is avoided, the use of the FR4 substrate is reduced, the production process and the production time are reduced, an effect of coating the FR4 substrate on the copper plate is better realized, and the circuit board is protected.

Owner:南通胜宏科技有限公司

Mold and method for improving warping of ultrathin plastic package body product

InactiveCN110491791AAvoid expansion and contractionImprove warpageSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringMechanical engineering

The invention relates to a mold and a method for improving warping of an ultrathin plastic package body product. The method comprises the following steps: step 1, designing an upper mold of an encapsulation mold into a peripheral slotted structure; step 2, mounting the upper mold of the peripheral slotted encapsulation mold at the position of an upper die of an encapsulation machine table; step 3,after the plastic package of the substrate is completed, forming a circle of reinforced step-shaped plastic package body around the whole substrate plastic package body; step 4, designing a pressingplate with a special-shaped structure according to the step-shaped plastic package body; step 5, overlapping the plurality of warped substrates in the same direction; step 6, pressing the special-shaped pressing plate in the middle of the plastic package body; and step 7, during post-curing, using the special-shaped pressing plate for pressurizing, and concentrating acting force in the middle of the plastic package body, so that the substrate and the plastic package body are subjected to reverse deformation. According to the invention, the structure of the plastic package body is changed through die design, and the specially designed special-shaped pressing plate is adopted for back pressing during post-curing, so that the problem of warping of the substrate can be effectively improved.

Owner:JCET GROUP CO LTD

A method of manufacturing a flexible circuit board

ActiveCN104168725BReduce cost pressureReduce processing costsPrinted element electric connection formationMolten statePolyimide substrate

The invention provides a flexible circuit board manufacturing method. The flexible circuit board manufacturing method at least comprises the following steps that 1, a first circuit board to be bonded and a second circuit board to be bonded are provided, wherein the first circuit board to be bonded and the second circuit board to be bonded respectively comprise a polyimide substrate and a copper line, each polyimide substrate is provided with a plurality of through holes, each copper line is formed on one face of the corresponding substrate, and the copper lines cover the through holes to serve as bonding pads; 2, the bonding pads, needing to be bonded, on the first circuit board to be bonded and the second circuit board to be bonded are stretched, and bonding pad convex points are formed on the to-be-bonded faces of the bonding pads; 3, the first circuit board to be bonded and the second circuit board to be bonded are stacked, so that the bonding pad convex points make contact to form junction points; 4, pulse voltage is exerted on the two ends of the jointed bonding pads so that welding current can be generated, and the junction points are at a high temperature instantaneously and in a molten state, so that the jointed bonding pads are welded in a fusion mode. The bonding pads are welded in the fusion mode in a pulse voltage spot welding mode, the flexible circuit board holes can be communicated and connected, the process is simple and efficient, and meanwhile good economic benefits and social benefits are obtained.

Owner:上海蓝沛信泰光电科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com