Interlayer interconnection technology

A technology of interlayer interconnection and process, applied in the direction of circuit lamination, electrical connection formation of printed components, electrical components, etc., can solve the problems of complex process and product expansion and contraction, and achieve the effect of simple steps and avoiding expansion and contraction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

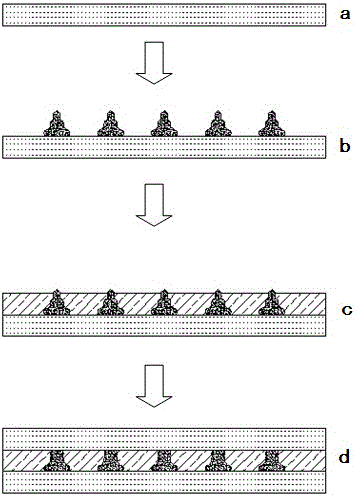

[0015] combined with figure 1 , to further describe the present invention:

[0016] An interlayer interconnection process mentioned in the present invention adopts the following steps:

[0017] a. It is to roughen the copper surface;

[0018] b. Use wire bonding equipment to make gold bumps on the copper surface that needs to be interconnected. The height of the gold bumps is 50~70um;

[0019] c. It is the covering glue layer, the glue thickness is 25um; the adhesive glue layer used can be any one of epoxy resin glue, acrylic glue or liquid crystal polymer glue.

[0020] d. The copper on the other side is thermally bonded to its opposite position at a temperature of 140 degrees for 4 hours to complete the interlayer interconnection.

[0021] The invention has the advantages of solving the problems in the prior art that the process is complicated and that the wet process has a great influence on the expansion and contraction of the product. The dry process is adopted in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com