Rigid-flex board for protecting inner layer window opening area and manufacturing method thereof

A technology of rigid-flex board and production method, applied in the field of rigid-flex board, can solve the problems of short circuit of rigid-flex board and the production efficiency of explosion board, and achieve the effect of saving production cost, avoiding internal stress and reducing the risk of board explosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

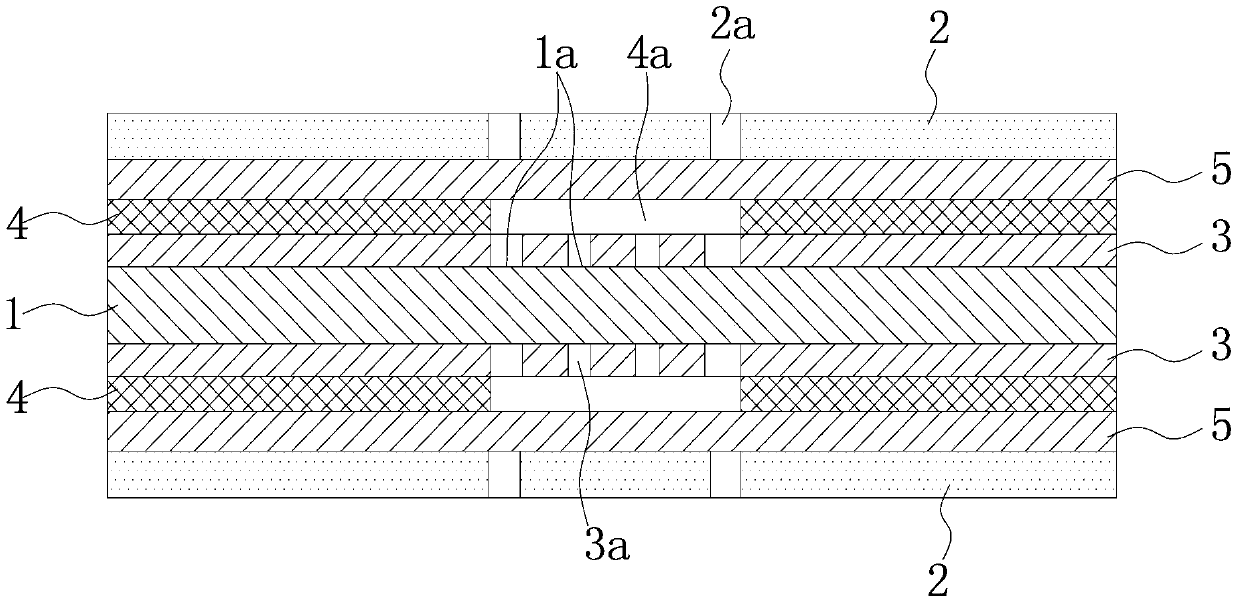

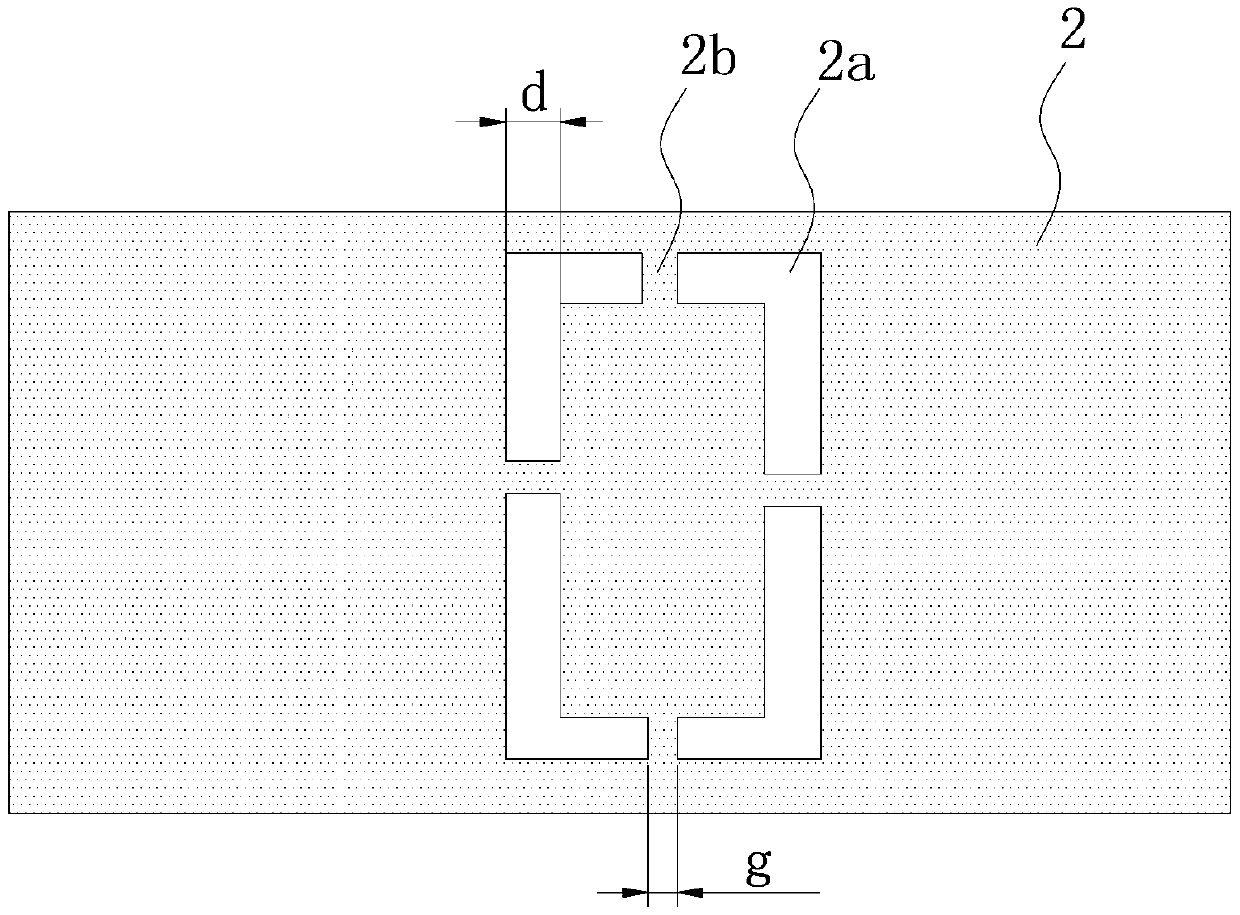

[0027] refer to figure 1 and figure 2 As shown, a rigid-flexible board for protecting the window opening area of the inner layer of the present invention includes a flexible board 1 and rigid boards 2 arranged on the upper and lower sides of the flexible board 1, and the window opening area on the flexible board 1 There are soldering pads or gold fingers 1a inside; between the flexible board 1 and the rigid board 2 on the upper and lower sides of the flexible board 1, a flexible board cover film 3 and a pure rubber film 4 are respectively arranged in sequence from the inside to the outside, The cover film 3 of the flexible board is provided with a cover film window 3a adapted to the pad or golden finger 1a, and the pure rubber film 4 is provided with a pure rubber film window 4a adapted to the window area; A covering film protective layer 5 is provided between the pure rubber film 4 and the rigid board 2; several slits 2a are arranged at intervals along the outer contour o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com