Lithium-ion battery negative electrode slurry, preparation method thereof, negative electrode sheet, and lithium-ion battery

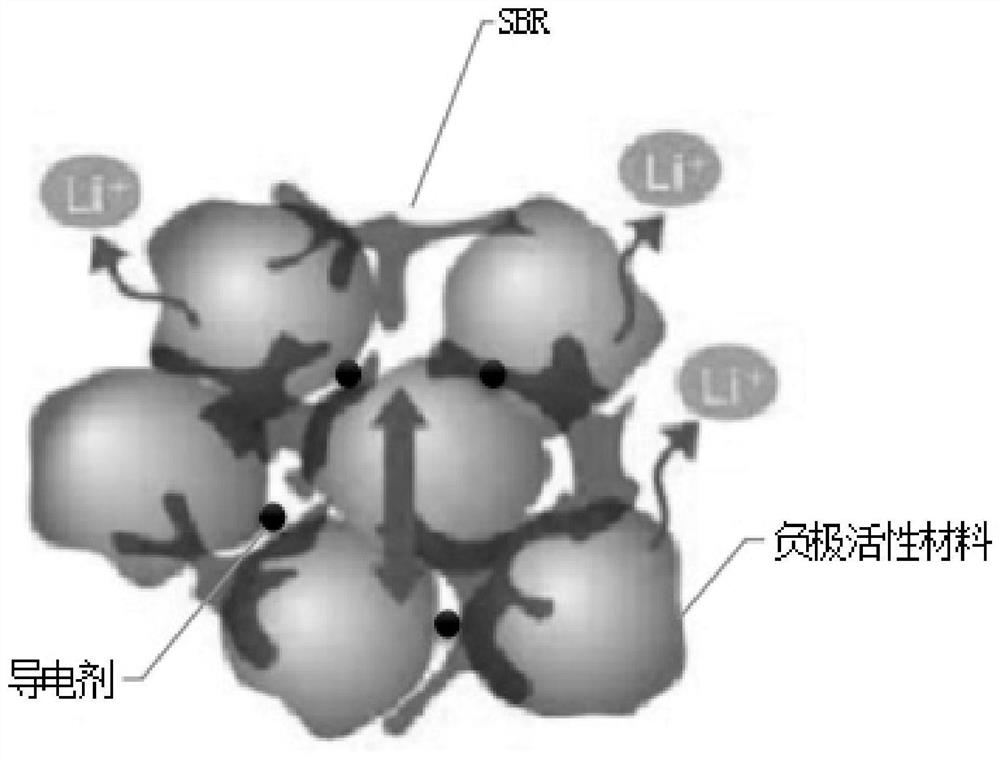

A lithium-ion battery, negative electrode slurry technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of poor cycle performance, easy increase in battery impedance, easy capacity decay, etc., to improve high-temperature storage, coating Good connection effect and good coating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] In one embodiment, the preparation method of the lithium ion battery negative electrode slurry at least includes the following steps:

[0042] Step S01. Weighing the above-mentioned negative electrode active material, conductive agent, binder, thickener, deionized water;

[0043] Step S02. Mix the weighed negative electrode active material, conductive agent, thickener, and part of deionized water to obtain a first slurry;

[0044]Step S03. Mix the remaining deionized water with the first slurry, adjust the viscosity, add the weighed binder, and continue stirring until the slurry is uniform to obtain a second slurry;

[0045] Step S04. Vacuumize and stir the second slurry obtained in step S03 to obtain negative electrode slurry.

[0046] The preparation method of the lithium-ion battery negative electrode slurry will be further explained below.

[0047] In a specific manufacturing process, the preparation of the above-mentioned lithium-ion battery negative electrode sl...

Embodiment 1

[0069] A lithium-ion battery negative electrode slurry, a preparation method thereof, a negative electrode sheet, and a lithium-ion battery.

[0070] Among them, the lithium-ion battery negative electrode slurry contains silicon carbon materials, Super P (D50 is about 1 μm), SBR (elastic modulus is 1.25MPa), CMC and deionized water;

[0071] Specifically, 94.5g of silicon carbon material, 2g of Super P, 2g of SBR, 1.5g of CMC, and 113g of deionized water.

[0072] The preparation method of the lithium ion battery negative electrode slurry is as follows:

[0073] Step S11. Weighing the above-mentioned negative electrode active material, conductive agent, binder, thickener, deionized water;

[0074] Step S12. Mix the weighed negative electrode active material, conductive agent, thickener, and 45g of deionized water, first stir at a stirring speed of 20r / min for 10min, premix the materials, and then mix them at 50r / min The stirring speed of min was stirred for 30min to obtain t...

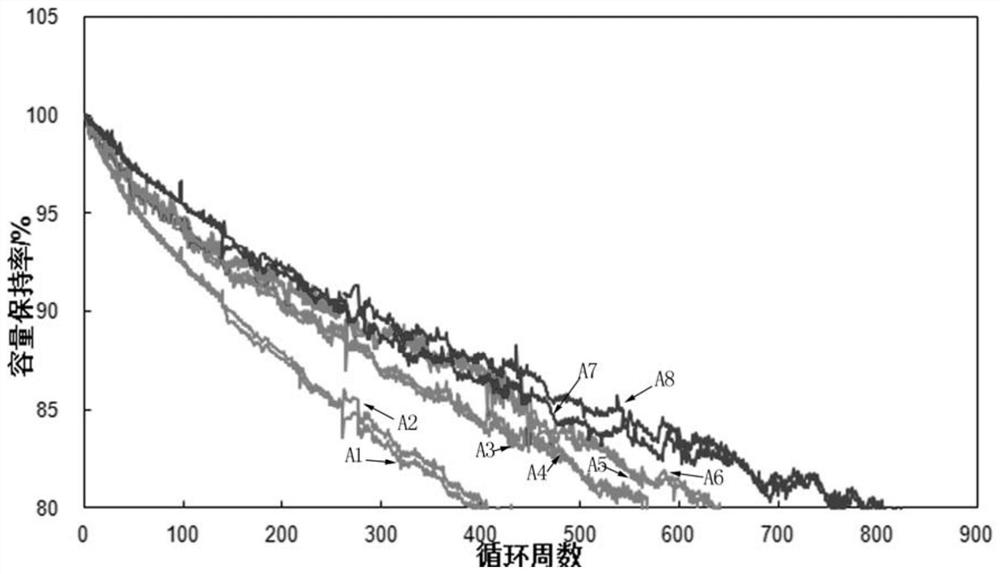

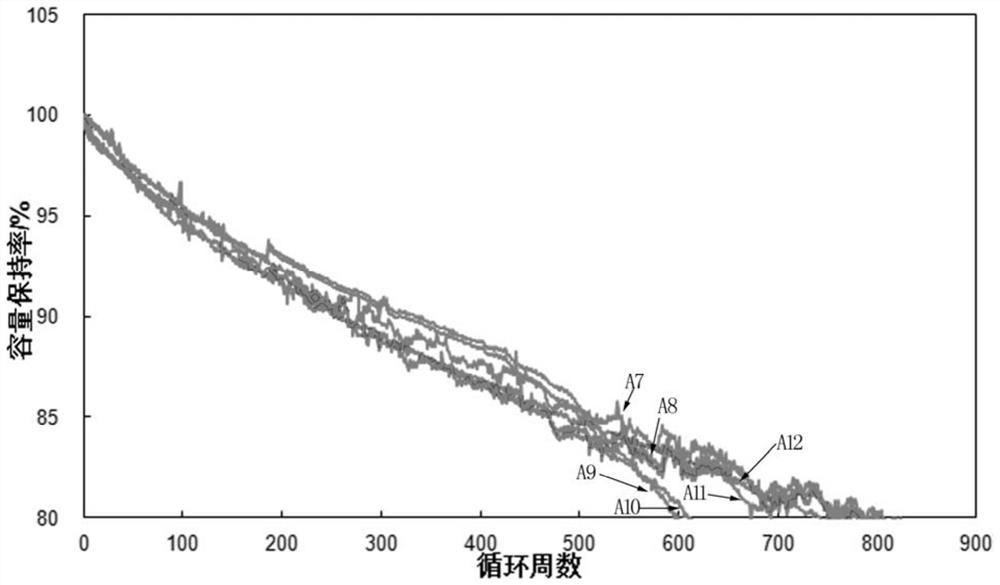

Embodiment 2

[0086] A lithium-ion battery negative electrode slurry, a preparation method thereof, a negative electrode sheet, and a lithium-ion battery.

[0087] Among them, the lithium-ion battery negative electrode slurry contains silicon carbon material, Super P conductive agent (D50 is about 1 μm), SBR (elastic modulus is 2.5MPa), CMC and deionized water;

[0088] Specifically, 94.5g of silicon carbon material, 2g of Super P, 2g of SBR, 1.5g of CMC, and 113g of deionized water.

[0089] The preparation method of the lithium ion battery negative electrode slurry is as follows:

[0090] Step S21. Weighing the above-mentioned negative electrode active material, conductive agent, binder, thickener, deionized water;

[0091] Step S22. Mix the weighed negative electrode active material, conductive agent, thickener, and 45g of deionized water, first stir at a stirring speed of 20r / min for 10min, premix the materials, and then mix them at 50r / min The stirring speed of min was stirred for 30...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com