Lithium manganate cathode material and preparation method thereof

A cathode material, lithium manganate technology, applied in the direction of positive electrode, chemical instruments and methods, manganate/permanganate, etc., can solve the contradiction between energy density and high temperature performance of lithium manganate material, reduce the specific capacity of cathode material , reduce the energy density of materials and other issues, to achieve the effect of improving high-temperature storage and high-temperature cycle performance, eliminating technical contradictions, and facilitating industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] The preparation formula is LiMn 1.97 m 0.03 o 4 Surface vitrified lithium manganate cathode material.

[0023] Lithium carbonate, manganese source (EMD) and additive B are fully mixed according to their elemental molar ratio of 1:1.97:0.03, then kept at 650°C for 4h and then at 850°C for 12 hours. After the heat preservation is completed, the temperature is directly lowered in the water circulation cooling zone. After cooling to room temperature, sieve to get the finished product.

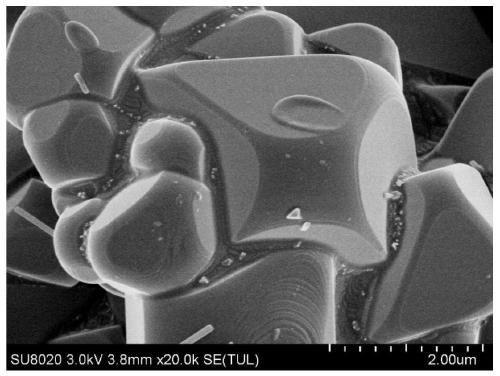

[0024] Depend on figure 1 It can be seen from the scanning electron microscope image in the figure that the surface of the obtained lithium manganate particles has obvious vitrification phenomenon. The sharp corners of the particles are basically eliminated.

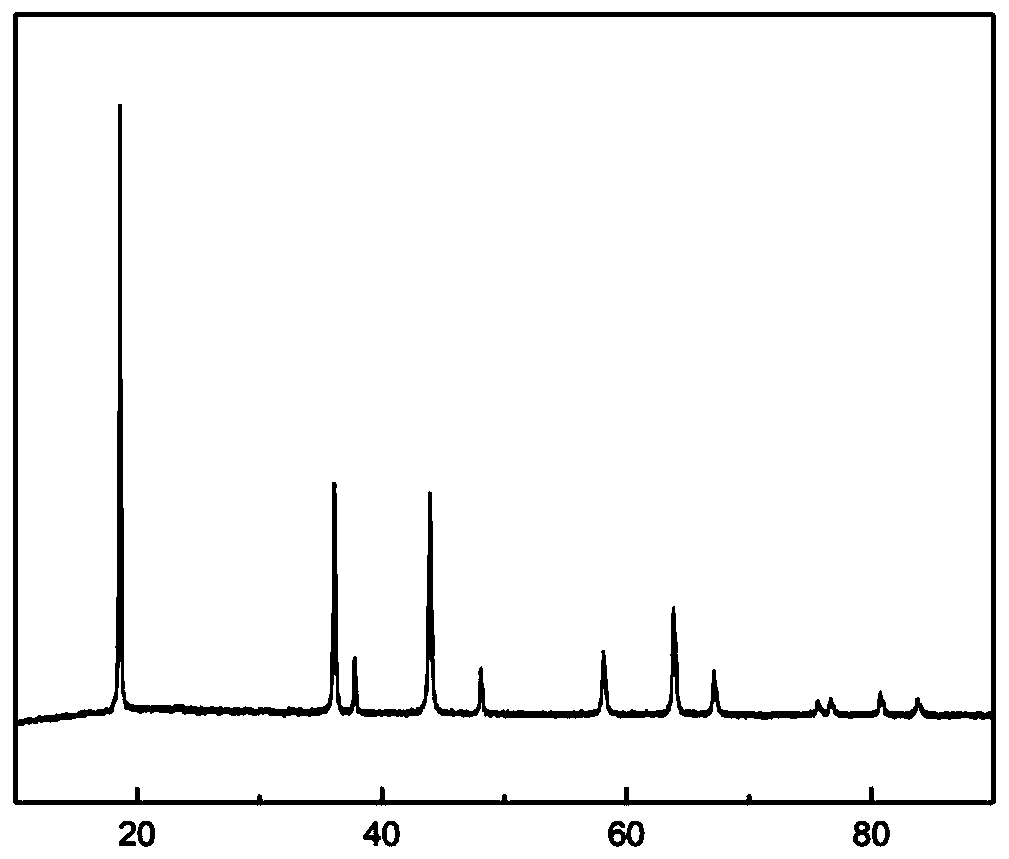

[0025] Depend on figure 2 It can be seen from the XRD pattern in the figure that the obtained lithium manganese oxide is a standard spinel phase, and no impurity phase exists.

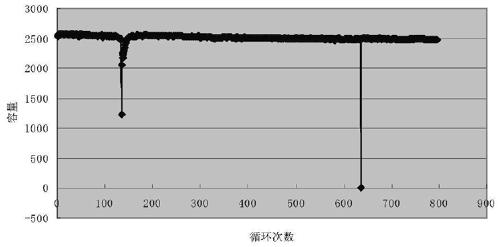

[0026] Depend on image 3 The high-temperature ...

Embodiment 2

[0028] The preparation formula is LiMn 1.99 m 0.01 o 4 Surface vitrified lithium manganate cathode material.

[0029] Lithium carbonate, manganese source (Mn 3 o 4 ) and additive S according to their elemental molar ratio of 1:1.95:0.01 are fully mixed, then kept at 450°C for 8h and then at 780°C for 14 hours. After the heat preservation is completed, the temperature is directly lowered in the water circulation cooling zone. After cooling to room temperature, sieve to get the finished product.

Embodiment 3

[0031] The preparation formula is LiMn 1.95 m 0.05 o 4 Surface vitrified lithium manganate cathode material.

[0032] Lithium carbonate, manganese source (Mn 3 o 4 ), additive S and additive Mg according to their elemental molar ratio of 1:1.95:0.02:0.03, after being fully mixed, they were kept at 580°C for 6 hours and then at 820°C for 8 hours. After the heat preservation is completed, the temperature is directly lowered in the water circulation cooling zone. After cooling to room temperature, sieve to get the finished product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com