Method for once molding inner-layer line of multilayer flexible circuit board

A flexible circuit board and inner layer circuit technology, applied in the direction of multi-layer circuit manufacturing, etc., can solve the problems of long production process, obvious high and low positions, and unrealistic dry film on the inner layer flexible board.

Active Publication Date: 2013-05-01

SHENZHEN XINYU TENGYUE ELECTRONICS

View PDF5 Cites 14 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0002] In the existing technology for producing flexible circuit boards, the commonly used production process for the inner layer circuit of four to eight layer boards is: the inner layer base material is stacked layer by layer and then pressed and solidified, and then the inner layer circuit is made. This method leads to After lamination of the soft board, the height of the glued area and the non-adhesive area are obvious, and the dry film of the inner soft board is not solid, and the soft board is expanded and shrunk after repeated pressing of the inner cover film, which eventually leads to The qualified rate of the product is low, and the production process of the prior art is long and the productivity is low

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

[0087] The technological parameter of table 1 embodiment

[0088]

[0089]

[0090]

[0091]

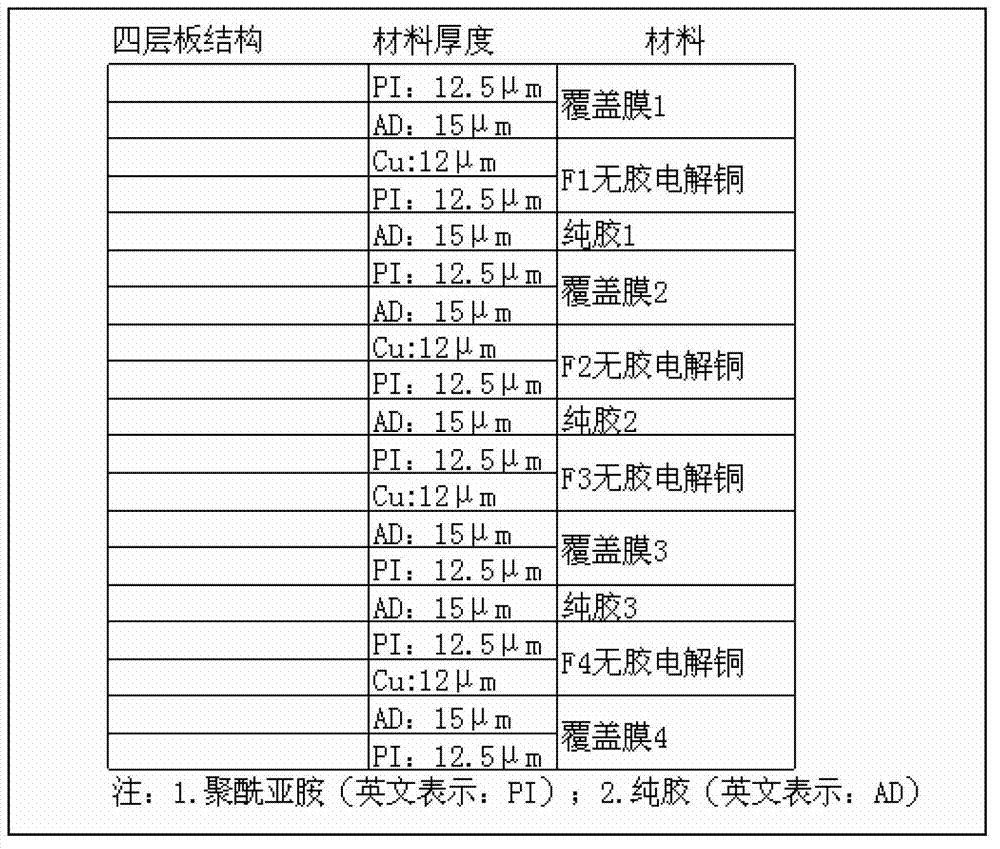

[0092] The structure of the multilayer flexible circuit board that embodiment makes is as image 3 As shown, after the conduction test, the pass rate of the multilayer flexible circuit board is 92%.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Login to View More

Abstract

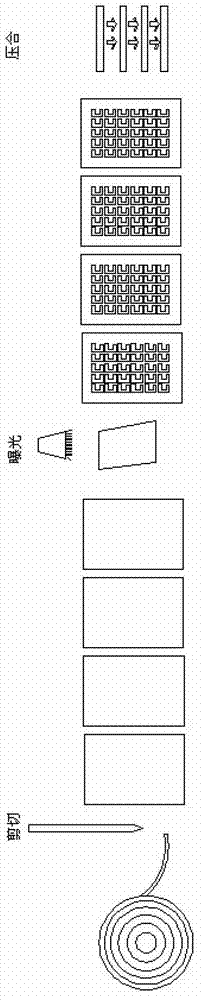

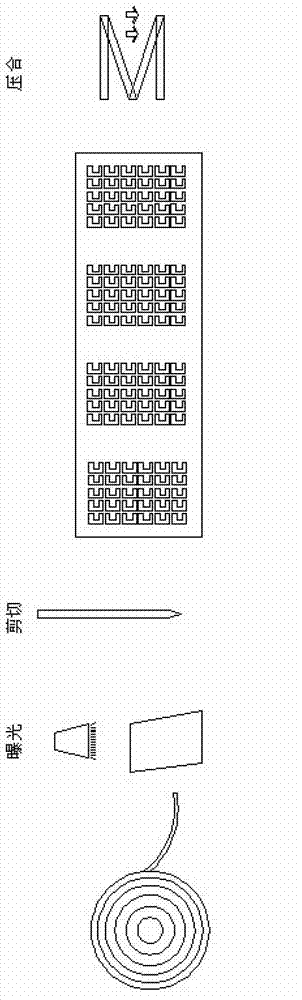

The invention discloses a method for once molding an inner-layer line of a multilayer flexible circuit board, and technical problems to be solved are improving the production efficiency and the qualified rate of products. The method for once molding the inner-layer line of the multilayer flexible circuit board comprises the following steps of: pasting a dry film in a whole roll, manufacturing an inner-layer line board of a multilayer board of a flexible circuit board, manufacturing an inner-layer line-board layer, manufacturing an inner-layer line-board combined layer, and manufacturing the inner-layer line of the multilayer flexible circuit board. Compared with the prior art, the processing flows of dry-film pasting, exposing, developing, etching, film removing, microetching and pressing are adopted by the invention to manufacture the inner-layer line board, the inner-layer line-board layer, the inner-layer line-board combined layer and the multilayer flexible circuit board, so that problems of height drop generated between a glued area and a non-glue area after inner-layer soft boards are pressed and expansion and shrinkage of the soft boards caused by pressing an inner-layer covering film for many times are avoided, the quality of the multilayer flexible circuit board is improved, the qualified rate reaches more than 92 percent, the process flow is shortened, and the production rate is improved.

Description

technical field [0001] The invention relates to a manufacturing process of a circuit board, in particular to a manufacturing process of a flexible circuit board. Background technique [0002] In the existing technology for producing flexible circuit boards, the commonly used production process for the inner layer circuit of four to eight layer boards is: the inner layer base material is stacked layer by layer and then pressed and solidified, and then the inner layer circuit is made. This method leads to After lamination of the soft board, the height of the glued area and the non-adhesive area are obvious, and the dry film of the inner soft board is not solid, and the soft board is expanded and shrunk after repeated pressing of the inner cover film, which eventually leads to The qualified rate of products is relatively low, and the production process flow of the prior art is long and the productivity is low. Contents of the invention [0003] The purpose of the present inv...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): H05K3/46

Inventor 苏锡明

Owner SHENZHEN XINYU TENGYUE ELECTRONICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com